Does the PCB Define the Color, or Does the Color Define the PCB?

In the market, PCBs for various board products come in a dizzying array of colors. Common ones include black, green, blue, yellow, purple, red, and brown; some manufacturers even innovate with unique hues like white and pink. A traditional misconception holds that black PCBs equal high-end products, while red or yellow ones are for low-end use—but is this true?

1.The Origin of Color: The Protective Mission of Solder Mask

First, uncoated PCB copper layers oxidize easily when exposed to air. Both sides of a PCB are copper layers, which end up with smooth, unprotected surfaces regardless of additive or subtractive manufacturing. Though less reactive than aluminum, iron, or magnesium, pure copper oxidizes rapidly in air (due to oxygen and moisture). Given the thin copper layers in PCBs, oxidized copper becomes a poor conductor, severely harming electrical performance.

To prevent this, separate soldering and non-soldering areas, and protect the PCB surface, engineers created solder mask—a special coating that forms a protective layer to block copper-air contact. Solder mask can be clear, but clear versions expose the PCB’s base color, making manufacturing, maintenance, and sales less user-friendly. Thus, pigments are added to create colored PCBs (green, black, red, blue, etc.).

2.The Quality Truth: Color is Unrelated to Performance

Crucially, PCB color has nothing to do with quality. A black PCB differs from a blue or yellow one only in solder mask color. With identical design and manufacturing, color never affects performance or heat dissipation. Black PCBs, however, hide surface traces, making post-production maintenance difficult. For this reason, manufacturers now increasingly abandon black solder mask in favor of dark green, dark brown, or dark blue—all for easier manufacturing and repair.

The “color equals high/low-end” myth stems from manufacturers using black PCBs for high-end products and other colors for low-end ones. In short: PCBs give meaning to colors, not the reverse.

Comparison of Cost and Production Characteristics by PCB Color

Color |

Relative Manufacturing Cost |

Production Complexity |

Typical Application Scenarios |

Green |

Baseline (1.0x) |

Low |

Consumer Electronics (75% market share), industrial control equipment |

Black |

2.0x |

High |

Military/Medical Equipment (EMI Shielding), high-end consumer electronics |

White |

2.5x |

High |

LED Lighting (85% light reflectivity), high-precision optical instruments |

Blue |

1.2x |

Medium |

Network Communication Equipment (high-frequency signals), high-end graphics cards |

Yellow |

1.5x |

Medium |

Automotive ECU Modules (high-temperature environments), aerospace sensors |

Red |

1.8x |

Medium |

Industrial Automation Equipment (high-temperature resistance), experimental prototype development |

Purple |

2.2x |

High |

Medical Imaging Equipment (optimized X-ray penetration), special optical devices |

3.Precious Coatings: For Performance, Not Luxury

As for precious metals (gold, silver) on PCBs: Some manufacturers highlight gold or silver plating in promotions, but this is not just a “high-end label.” PCBs need exposed copper areas (called pads) for component soldering. These pads oxidize easily, leading to poor solderability and higher resistivity—ruining end-product performance. Thus, engineers protect pads by plating inert metals (gold), applying silver via chemical processes, or using special chemical films. The goal is to prevent oxidation and ensure soldering yield rates.

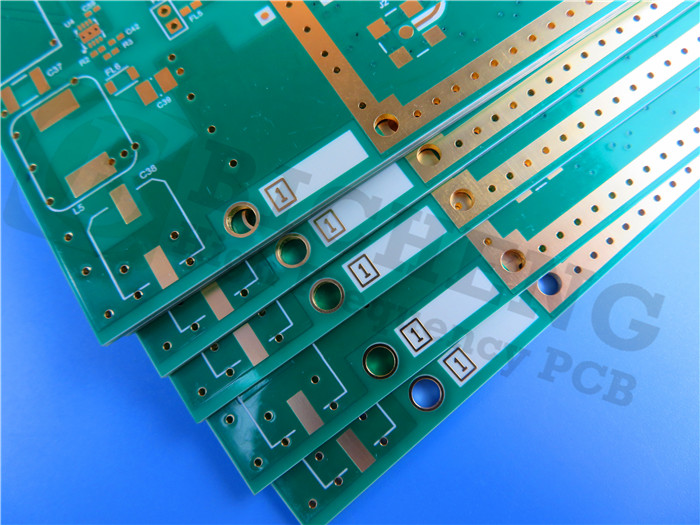

RO4003C LoPro ENIG PCB with Green Solder Mask

4.Core Conclusion: Function Defines Color

In summary, PCB color is determined by solder mask (for oxidation resistance, soldering separation, and protection) and unrelated to quality. Precious metal coatings on pads exist to safeguard performance, not signal luxury. Ultimately, PCBs define color meaning—not the other way around.

Home

Home