Home

-

Flexible Circuit Boards

-

Transparent Flexible Printed Circuit FPC On PET Substrate for Power Battery Market PCB and Microwave Amplifier

Home

-

Flexible Circuit Boards

-

Transparent Flexible Printed Circuit FPC On PET Substrate for Power Battery Market PCB and Microwave Amplifier

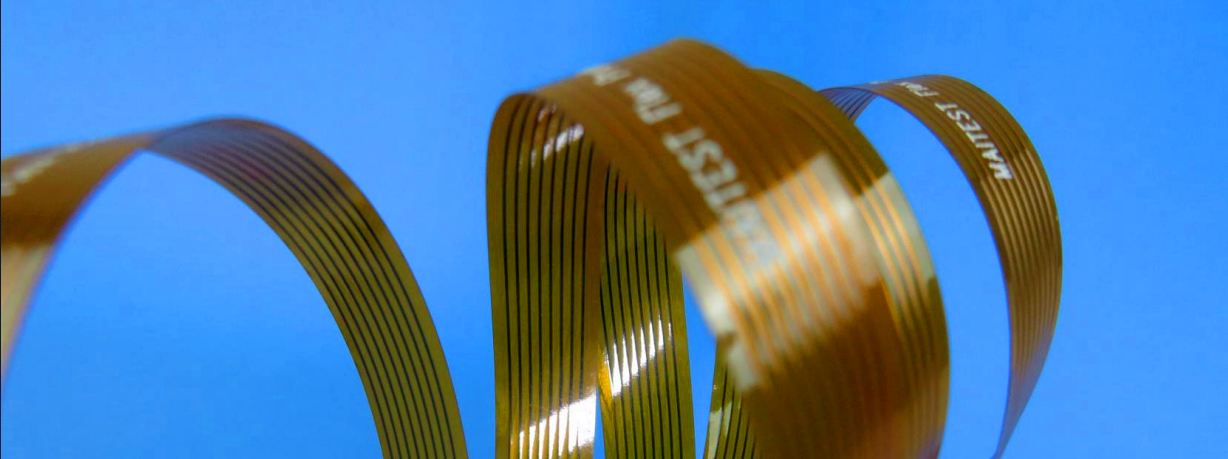

Transparent Flexible Printed Circuit FPC On PET Substrate for Power Battery Market PCB and Microwave Amplifier

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

General Description

This type of flexible printed circuit is constructed on PET material for microwave amplifier applications. It is a single-layer FPC with a thickness of 0.15mm. The base laminate is sourced from Shengyi, and it is fabricated in accordance with IPC 6012 Class 2 using the provided Gerber data. A polyimide stiffener is applied to the insertion part.

.jpg)

Parameter and data sheet

| Size of Flexible PCB | 70.18 X 68.28mm |

| Number of Layers | 1 |

| Board Type | Flexible PCB |

| Board Thickness | 0.15mm |

| Board Material | PET 25µm |

| Board Material Supplier | ITEQ |

| Tg Value of Board Material | 60℃ |

| PTH Cu thickness | N/A |

| Inner Iayer Cu thicknes | N/A |

| Surface Cu thickness | 35 µm |

| Coverlay Colour | Transparent |

| Number of Coverlay | 2 |

| Thickness of Coverlay | 25 µm |

| Stiffener Material | Polyimide |

| Stiffener Thickness | 0.2mm |

| Type of Silkscreen Ink | IJR-4000 MW300 |

| Supplier of Silkscreen | TAIYO |

| Color of Silkscreen | Black |

| Number of Silkscreen | 1 |

| Peeling test of Coverlay | No peelable |

| Legend Adhesion | 3M 90℃ No peeling after Min. 3 times test |

| Surface Finish | Immersion Gold |

| Thickness of Nickle/Gold | Au: 0.03µm(Min.); Ni 2-4µm |

| RoHS Required | Yes |

| Famability | 94-V0 |

| Thermal Shock Test | Pass, -25℃±125℃, 1000 cycles. |

| Thermal Stress | Pass, 300±5℃,10 seconds, 3 cycles. No delamination, no blistering. |

| Function | 100% Pass electrical test |

| Workmanship | Compliance with IPC-A-600H & IPC-6013C Class 2 |