Home

-

Antenna PCB

-

Rogers RT Duroid 5880 PTFE Composite PCB 10mil 20mil 31mil 62mil Thickness with Immersion Gold, Immersion Silver, Immersion Tin and HASL

Home

-

Antenna PCB

-

Rogers RT Duroid 5880 PTFE Composite PCB 10mil 20mil 31mil 62mil Thickness with Immersion Gold, Immersion Silver, Immersion Tin and HASL

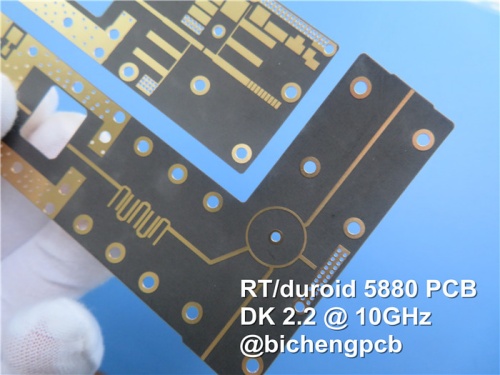

Rogers RT Duroid 5880 PTFE Composite PCB 10mil 20mil 31mil 62mil Thickness with Immersion Gold, Immersion Silver, Immersion Tin and HASL

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

Product Introduction

We present a high-performance RF circuit board fabricated using Rogers RT/duroid 5880 high-frequency laminates. Rogers RT/duroid 5880 PCB delivers exceptional electrical properties for demanding microwave and millimeter-wave applications, available in multiple thickness configurations (10mil, 20mil, 31mil, 62mil) with comprehensive surface treatment options including Immersion Gold, Immersion Silver, Immersion Tin, and HASL.

Material Advantages

Rogers RT/duroid 5880 PCB board material incorporates glass microfiber reinforced PTFE composition, delivering outstanding performance for precision stripline and microstrip circuits. Key benefits of RT/duroid 5880 laminates include:

Exceptional dielectric constant uniformity through randomly oriented microfibers

Consistent dielectric stability across panels and wide frequency ranges

Ultra-low dissipation factor (0.0004 @ 1MHz to 0.0009 @ 10GHz) enabling reliable performance through Ku-band and beyond

Versatile configuration support for double-layer boards, multilayer constructions, and hybrid designs

Characteristic black substrate appearance with low water absorption and superior chemical resistance

.jpg)

Application Spectrum

Rogers RT/duroid 5880 RF PCB is engineered for advanced applications including:

Precision microstrip and stripline circuits

Commercial airline broadband antennas

Radar systems and millimeter-wave devices

Point-to-point digital radio antennas

.jpg)

PCB Cababiltity (RT/duroid 5880)

PCB Material: |

Glass microfiber reinforced PTFE composites |

Designation: |

RT/duroid 5880 |

Dielectric constant: |

2.2 ±0.02 (process) |

|

2.2 (design) |

Layer count: |

2 Layer, Multilayer, Hybrid type (Mixed) |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

PCB thickness: |

10mil (0.254mm), 20mil (0.508mm) |

|

31mil (0.787mm), 62mil (1.575mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, OSP, etc.. |

RT/duroid 5880 PCB material can be made in double layer board, multilayer board and hybrid types. The double sided boards are available in a variety of thicknesses, such as 10mil, 20mil, 31mil and 62mil.

Technical Support

Rogers RT/duroid 5880 based solutions are backed by comprehensive technical expertise. Contact our engineering team to discuss how these high-frequency PCBs can optimize your specific application requirements.

The basic colour of RT/duroid 5880 PCB is black.

Rogers RT/duroid 5880 PCB also has the properties of low water absorption, excellent chemical resistance etc.

If you have any questions, please feel free to contact us.

Thank you for your reading.

Appendix: Typical Values of Rogers 5880

| RT/duroid 5880 Typical Value | ||||||

| Property | RT/duroid 5880 | Direction | Units | Condition | Test Method | |

| Dielectric Constant,εProcess | 2.20 2.20±0.02 spec. |

Z | N/A | C24/23/50 C24/23/50 |

1 MHz IPC-TM-650 2.5.5.3 10 GHz IPC-TM 2.5.5.5 |

|

| Dielectric Constant,εDesign | 2.2 | Z | N/A | 8GHz to 40 GHz | Differential Phase Length Method | |

| Dissipation Factor,tanδ | 0.0004 0.0009 |

Z | N/A | C24/23/50 C24/23/50 |

1 MHz IPC-TM-650 2.5.5.3 10 GHz IPC-TM 2.5.5.5 |

|

| Thermal Coefficient of ε | -125 | Z | ppm/℃ | -50℃to 150℃ | IPC-TM-650 2.5.5.5 | |

| Volume Resistivity | 2 x 107 | Z | Mohm cm | C/96/35/90 | ASTM D 257 | |

| Surface Resistivity | 3 x 107 | Z | Mohm | C/96/35/90 | ASTM D 257 | |

| Specific Heat | 0.96(0.23) | N/A | j/g/k (cal/g/c) |

N/A | Calculated | |

| Tensile Modulus | Test at 23℃ | Test at 100℃ | N/A | MPa(kpsi) | A | ASTM D 638 |

| 1070(156) | 450(65) | X | ||||

| 860(125) | 380(55) | Y | ||||

| Ultimate Stress | 29(4.2) | 20(2.9) | X | |||

| 27(3.9) | 18(2.6) | Y | ||||

| Ultimate Strain | 6 | 7.2 | X | % | ||

| 4.9 | 5.8 | Y | ||||

| Compressive Modulus | 710(103) | 500(73) | X | MPa(kpsi) | A | ASTM D 695 |

| 710(103) | 500(73) | Y | ||||

| 940(136) | 670(97) | Z | ||||

| Ultimate Stress | 27(3.9) | 22(3.2) | X | |||

| 29(5.3) | 21(3.1) | Y | ||||

| 52(7.5) | 43(6.3) | Z | ||||

| Ultimate Strain | 8.5 | 8.4 | X | % | ||

| 7.7 | 7.8 | Y | ||||

| 12.5 | 17.6 | Z | ||||

| Moisture Absorption | 0.02 | N/A | % | 0.62""(1.6mm) D48/50 | ASTM D 570 | |

| Thermal Conductivity | 0.2 | Z | W/m/k | 80℃ | ASTM C 518 | |

| Coefficient of Thermal Expansion | 31 48 237 |

X Y Z |

ppm/℃ | 0-100℃ | IPC-TM-650 2.4.41 | |

| Td | 500 | N/A | ℃ TGA | N/A | ASTM D 3850 | |

| Density | 2.2 | N/A | gm/cm3 | N/A | ASTM D 792 | |

| Copper Peel | 31.2(5.5) | N/A | Pli(N/mm) | 1oz(35mm)EDC foil after solder float |

IPC-TM-650 2.4.8 | |

| Flammability | V-0 | N/A | N/A | N/A | UL 94 | |

| Lead-free Process Compatible | Yes | N/A | N/A | N/A | N/A |