How to Choose Copper Thickness for Thick Copper PCBs?

You may not have paid much attention to the copper thickness on PCBs, but it actually determines the current a product can withstand, its heat generation, and its service life. To put it simply: copper thickness = number of lanes on a highway. Too few lanes (too thin copper) cause current "traffic jams" and severe heat; too many lanes (too thick copper), while unobstructed, lead to higher costs and more difficult processing.

In fields like new energy, energy storage, drones, high-power motors, and industrial power supplies, thick copper PCBs are almost a standard configuration. Shenzhen Bicheng Electronic Technology Co., Ltd. can provide thick copper PCBs ranging from 2oz to 12oz and has delivered solutions for hundreds of high-current control and new energy projects.

1.What Are the Standards for PCB Copper Thickness?

In the PCB industry, copper thickness is commonly measured in ounces (oz), typically referring to the weight of copper foil per square foot. The conversion to thickness is as follows:

Copper Thickness (oz) |

Thickness (μm) |

Common Applications |

0.5oz |

17μm |

High-frequency signal boards, light-load products |

1oz |

35μm |

Conventional consumer electronics, general industrial control |

2oz |

70μm |

Medium-current products, power supply boards |

3oz |

105μm |

High-current control boards, industrial power supplies |

6oz |

210μm |

Energy storage, new energy vehicle BMS, charging piles |

10~12oz |

350~420μm |

Extra-high-current, special industrial equipment |

Quick tip: In the industry, PCBs with ≥2oz copper are generally called thick copper PCBs, while those with >10oz are extra-thick copper PCBs.

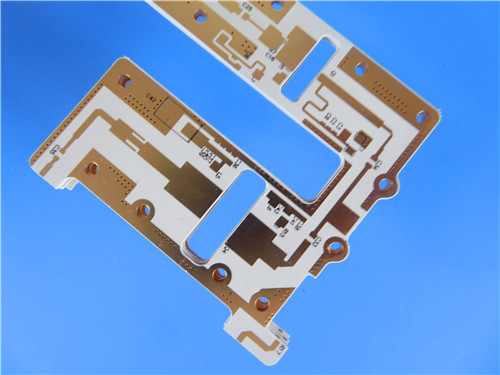

2-layer Rogers TC350 2OZ ENIG PCB

2.Where are thick copper PCBs used?

To determine if you need a thick copper PCB, refer to the following conditions:

Current > 5A with long circuit paths

Severely heat-generating power components on the board

Products requiring long-term full-load operation

High ambient temperature with heat dissipation requirements

Common applications:

Industrial power supplies, photovoltaic inverters, energy storage systems

New energy vehicle OBCs, BMS, high-voltage power distribution units

High-power motor drives, charging piles, rail transit power supplies

Special military and aerospace equipment

3.What If You Choose Too Thick Copper?

Thick copper not only boosts current-carrying capacity but also lowers temperature rise and extends service life. For instance: With the same 10A current, a 3oz copper layer sees a temperature rise over 20℃ lower than a 1oz one, which clearly benefits component longevity.

Though thick copper has merits, thicker isn’t always better. Potential issues include:

Higher cost: More copper foil consumption, longer plating time, and increased processing costs.

Wiring limitations: Thicker copper means stricter minimum line width/space restrictions.

Diminished pattern precision: Etching gets harder, leading to irregular edges.

Longer lead time: Thick copper lamination and processing take 1-3 days longer than conventional PCBs.

We recommends: Use thick copper only in high-current areas and keep conventional copper thickness elsewhere (achievable via “local thick copper” or “copper coin embedding”). This balances performance, cost, and lead time.

4. Why Choose Us for Thick Copper PCBs?

Shenzhen Bicheng Electronics Technology Co., Ltd. offers PCBs with various copper thicknesses and multiple types to meet your diverse needs.

Our company supports up to 12oz max internal/external copper thickness (specialized in Heavy Copper PCBs), paired with high-performance substrates (High Tg FR-4, Rogers, Wangling, Taconic) for stable high-current/thermal performance.

We ensure precision: 3mil/3mil min line width/spacing, strict impedance tolerance (<50Ω±5Ω; ≥50Ω±10%), and up to 32-layer design. Quality is guaranteed by ISO9001&14001 certification, UL-94 V0 flammability rating, IPC-Class-2 standard, plus 100% electrical test & AOI inspection.

Ideal for new energy, industrial power, 5G—choose Bicheng for reliable thick copper PCB solutions!

Home

Home