Can You Distinguish Between PTH and NPTH on a PCB?

In our daily interactions with printed circuit boards (PCBs), we often notice numerous holes of various sizes. Some are used for soldering components, others for securing the board, and some may seem inconspicuous but play a critical role in establishing electrical connections. These holes can generally be categorized into two types: PTH (Plated Through Hole) and NPTH (Non-Plated Through Hole).

This article will delve into their structures, functions, and key differences to help you gain a clear understanding!

1.What Are PTH and NPTH?

The most significant difference between PTH and NPTH lies in whether the hole walls are plated with a copper layer.

Picture 1: Left shows PTH (with copper plating), right shows NPTH (without copper plating)

PTH: The hole walls are plated with copper, making them conductive and enabling electrical connections between different layers of the PCB.

NPTH: The hole walls are bare and non-conductive, serving only mechanical or structural purposes.

2.The Role of PTH

PTH is essential for establishing electrical connections between different layers of a PCB. Its common applications include:

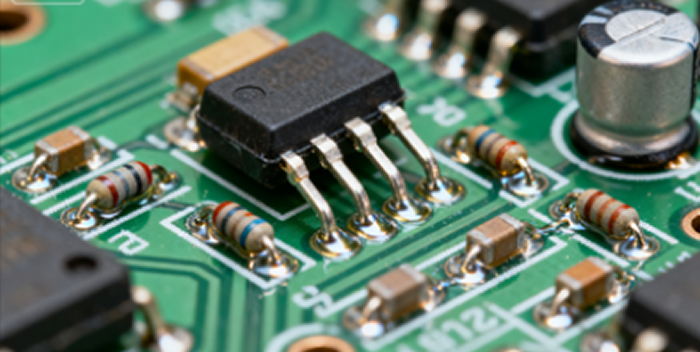

2.1 Soldering Through-Hole Components (e.g., DIP Components)

Typical examples include resistors, capacitors, and inductors with pin leads.

The hole diameter is designed to be slightly larger than the component pins to facilitate insertion and soldering.

Picture 2: Soldering of through-hole components in PTH

2.2 Signal Transmission (Commonly Known as "Via")

In practical PCB designs, smaller PTHs, known as vias, are used to connect copper traces across different layers.

Vias are indispensable in high-speed or high-density PCB designs and are essentially a smaller, more densely packed form of PTH.

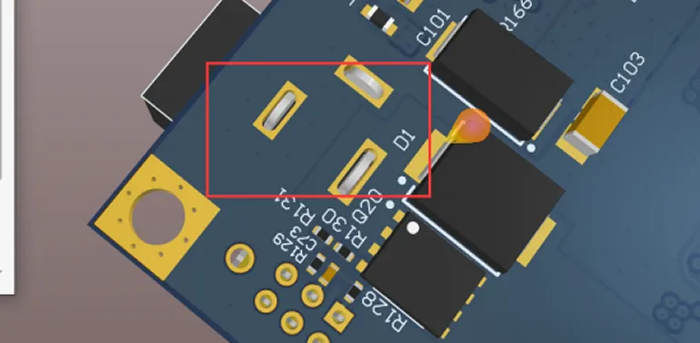

3. What Is the Purpose of NPTH?

NPTHs are larger and non-conductive, so what are they used for?

In fact, NPTHs play a crucial role in mechanical and structural applications:

Screw Mounting: Used for securing the PCB to enclosures, heat sinks, or other structural components.

Securing External Interfaces/Connectors: Providing mechanical support for connectors and ports.

Test Fixture Alignment: Serving as positioning holes for testing and alignment during assembly.

Picture 3: Typical NPTH applications (screw holes and alignment pins)

Generally, NPTHs have larger diameters and do not conduct electricity within the board. Their primary purpose is to ensure structural integrity or facilitate installation.

4. Summary

Below is a comparison table highlighting the differences between PTH and NPTH:

Feature |

PTH (Plated Through Hole) |

NPTH (Non-Plated Through Hole) |

Plating |

✅ Copper-plated |

❌ No copper plating |

Conductivity |

✅ Conductive |

❌ Non-conductive |

Application |

Soldering/inter-layer signal transmission (including vias) |

Screw mounting, positioning, structural support |

Common Size |

Generally smaller (vias are even smaller) |

Generally larger, for structural components |

Necessity |

Essential for all multi-layer boards |

Used based on structural requirements |

Although PTH and NPTH are merely "holes" on a PCB, they are critical to both the electrical and mechanical performance of the board. It is essential to distinguish between them during the design phase to avoid potential production issues or functional defects.

By understanding the distinct roles of PTH and NPTH, designers can optimize PCB layouts for better performance, reliability, and manufacturability. Whether you are designing high-speed circuits or robust mechanical assemblies, paying attention to these details will ensure your PCB meets all electrical and structural requirements.

Home

Home