Home

-

Standard PCB

-

Taconic TSM-DS3 High-Frequency PCB Double-Sided 30mil Taconic Substrate with 1oz Copper and Immersion Gold Finish

Home

-

Standard PCB

-

Taconic TSM-DS3 High-Frequency PCB Double-Sided 30mil Taconic Substrate with 1oz Copper and Immersion Gold Finish

Taconic TSM-DS3 High-Frequency PCB Double-Sided 30mil Taconic Substrate with 1oz Copper and Immersion Gold Finish

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

Brief Introduction

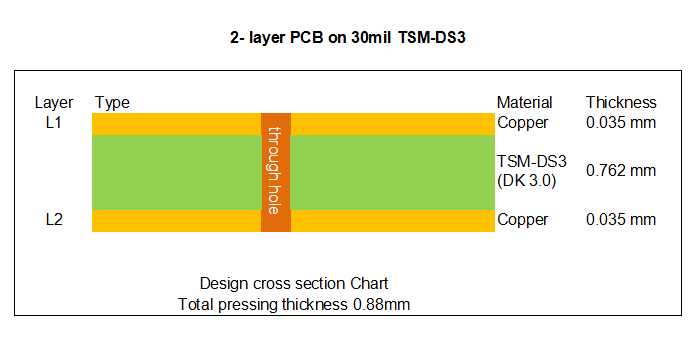

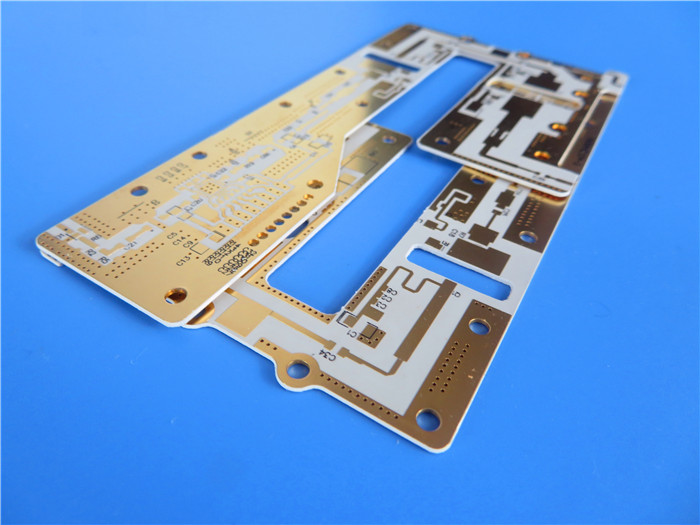

This Taconic TSM-DS3 high-frequency PCB is a 2-layer rigid board engineered for demanding RF and microwave applications. 2-Layer Taconic TSM-DS3 PCB board features a 0.762mm (30mil) TSM-DS3 core material clad with 35μm copper layers on both sides, resulting in a finished thickness of 0.88mm. With dimensions of 120mm × 75mm (±0.15mm tolerance), this Taconic TSM-DS3 circuit board supports 7/8 mil trace/space design rules and 0.3mm minimum hole size, enabling precise high-frequency circuit implementation.

Taconic TSM-DS3 PCB utilizes 1oz finished copper weight on outer layers with 20μm via plating thickness, ensuring reliable electrical connections. The immersion gold surface finish provides excellent solderability and environmental protection, while the black top silkscreen facilitates component placement. Manufactured without solder mask on either side, this Taconic TSM-DS3 high-frequency board undergoes 100% electrical testing prior to shipment, guaranteeing performance and reliability in critical applications.

PCB Specifications

| PCB SIZE | 120 x 75mm=1up |

| BOARD TYPE | Double sided PCB |

| Number of Layers | 2 layers |

| Surface Mount Components | YES |

| Through Hole Components | NO |

| LAYER STACKUP | copper ------- 18um(0.5 oz)+plate TOP layer |

| TSM-DS3 0.762mm | |

| copper ------- 18um(0.5oz) + plate BOT Layer | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 7 mil / 8 mil |

| Minimum / Maximum Holes: | 0.3 mm / 2.5 mm |

| Number of Different Holes: | 11 |

| Number of Drill Holes: | 72 |

| Number of Milled Slots: | 1 |

| Number of Internal Cutouts: | 1 |

| Impedance Control: | no |

| Number of Gold finger: | 0 |

| BOARD MATERIAL | |

| Ceramic-filled Fiberglass | TSM-DS3 |

| Final foil external: | 1.0 oz |

| Final foil internal: | N/A |

| Final height of PCB: | 0.88 mm ±0.1 |

| PLATING AND COATING | |

| Surface Finish | Immersion gold, 49% |

| Solder Mask Apply To: | N/A |

| Solder Mask Color: | N/A |

| Solder Mask Type: | N/A |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | Top Side |

| Colour of Component Legend | Black |

| Manufacturer Name or Logo: | N/A |

| VIA | Plated through hole(PTH), minimum size 0.3mm. |

| FLAMIBILITY RATING | 94 V0 |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059"" |

| Board plating: | 0.0029"" |

| Drill tolerance: | 0.002"" |

| TEST | 100% Electrical Test prior shipment |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

Our PCB Capability (2025)

| Factory Process Capability (2025) | |

| Substrate Types | Standard FR-4, High Tg FR-4, High Frequency Materials, Rigid Polyimide, Flexible Polyimide, Transparent PET Materials, AL2O3 Ceramic, AlN Ceramic etc. |

| Substrate Brands | Shengyi, ITEQ, KB, Isola, Taiwan Union, Rogers Corp. Taconic, Wangling, Panasonic etc |

| Board Types | Rigid PCB, Flexible Circuits, Rigid-Flex PCB, Hybrid PCB, HDI PCB, Heavy Copper, High Speed, High frequency etc. |

| Copper Clad Laminates(CCL) | High Tg FR-4: S1000-2M, TU-872 SLK, TU-768, TU-883, IT-180A, FR408HR, 370HR, High CTI FR-4: S1600L, ST115 High speed: M6 (R5775G Core / R-5670 Prepreg) |

| Rogers Corp: RO4350B, RO4003C, RO4725JXR, RO4730G3, RO4360G2, RO4533, RO4534, RO4535, RO4830, RO4835, RO3003, RO3006, RO3010, RO3035, RO3203, RO3210; RT/Duriod 5880; RT/Duriod 5870, RT/Duriod 6002, RT/duroid 6006, RT/Duroid 6010.2LM, RT/duroid 6035HTC; RT/duroid 5880LZ, RT/duroid 6202; TMM3, TMM4, TMM6, TMM10, TMM10i, TMM13i, Kappa 438; AD250C, AD255C, AD300D, AD350A, AD450, AD600, AD1000, TC350; TC600; DiClad 880, DiClad 870, DiClad 527; IsoClad 917, IsoClad 933; CLTE-XT, CLTE-AT, CLTE-MW; CuClad 217, CuClad 233, CuClad 250. | |

| Taconic: TLF-35; RF-35TC, RF-60A, RF-60TC, RF-35A2,RF-30, RF-35, RF-45, RF-10, TRF-45; TLX-0, TLX-6, TLX-7, TLX-8; TLX-9, TLY-3, TLY-5, TLY-5Z; CER-10; TSM-DS3 | |

| Wangling: F4BM217, F4BM220, F4BM233, F4BM245, F4BM255, F4BM265, F4BM275, F4BM294, F4BM300; F4BME217, F4BME220, F4BME233, F4BME245, F4BME255, F4BME265, F4BME275, F4BME294, F4BME300; F4BTM298, F4BTM300, F4BTM320, F4BTM350; F4BTME298, F4BTME300, F4BTME320, F4BTME350; TP300, TP440, TP600, TP615, TP960, TP1020, TP1100, TP1600, TP2000, TP2200, TP2500; TF300, TF440, TF600, TF960, TF1020, TF1600; F4BTMS220, F4BTMS233, F4BTMS255, F4BTMS265, F4BTMS294, F4BTMS300, F4BTMS350, F4BTMS430, F4BTMS450, F4BTMS615, F4BTMS1000; TFA294, TFA300, TFA615, TFA1020; WL-CT300, WL-CT330, WL-CT330Z, WL-CT338, WL-CT350, WL-CT440, WL-CT615. |

|

| Maximum Delivery Size | 1200mm x 572 mm |

| Minimum Finished Board Thickness | L≤2L: 0.15mm; 4L: 0.4mm |

| Maximum Finished Board Thickness | 10.0 mm |

| Blind Buried Holes (Non-crossing) | 0.1mm |

| Maximum Hole Aspect Ratio | 15:01 |

| Minimum Mechanical Drill Hole Diameter | 0.1 mm |

| Through-hole Tolerance | +/- 0.0762 mm |

| Press-fit Hole Tolerance | +/- 0.05mm |

| Non-plated Copper Hole Tolerance | +/- 0.05mm |

| Maximum Number of Layers | 32 |

| Internal and External Layer Maximum Copper Thickness | 12Oz |

| Minimum Drill Hole Tolerance | +/- 2mil |

| Minimum Layer-to-Layer Tolerance | +/- 3mil |

| Minimum Line Width/Spacing | 3mil/3mil |

| Minimum BGA Diameter | 8mil |

| Impedance Tolerance | < 50Ω ±5Ω; ≥50Ω±10% |

| Special Technology | High density interconnection (HDI), Hybrid design/ mixed PCB, Blind/Buried vias, Resin filled / copper filled and capped, Copper coin embedded, Staircase PCB, Edge plated PCB, Heavy copper PCB, Half holes/castled Edge holes, Thick PCB etc |

| Surface Treatment Processes | Leaded/Lead-free HASL, Immersion Gold, Immersion Silver, Immersion Tin, OSP, ENIG, ENEPIG, Pure gold, Carbon Ink, Peelable Mask, Gold Finger, etc. |