Home

-

Standard PCB

-

6-Layer S1000-2M PCB HDI Printed Circuit Board 90 Ohm Impedance Control HASL Finish

Home

-

Standard PCB

-

6-Layer S1000-2M PCB HDI Printed Circuit Board 90 Ohm Impedance Control HASL Finish

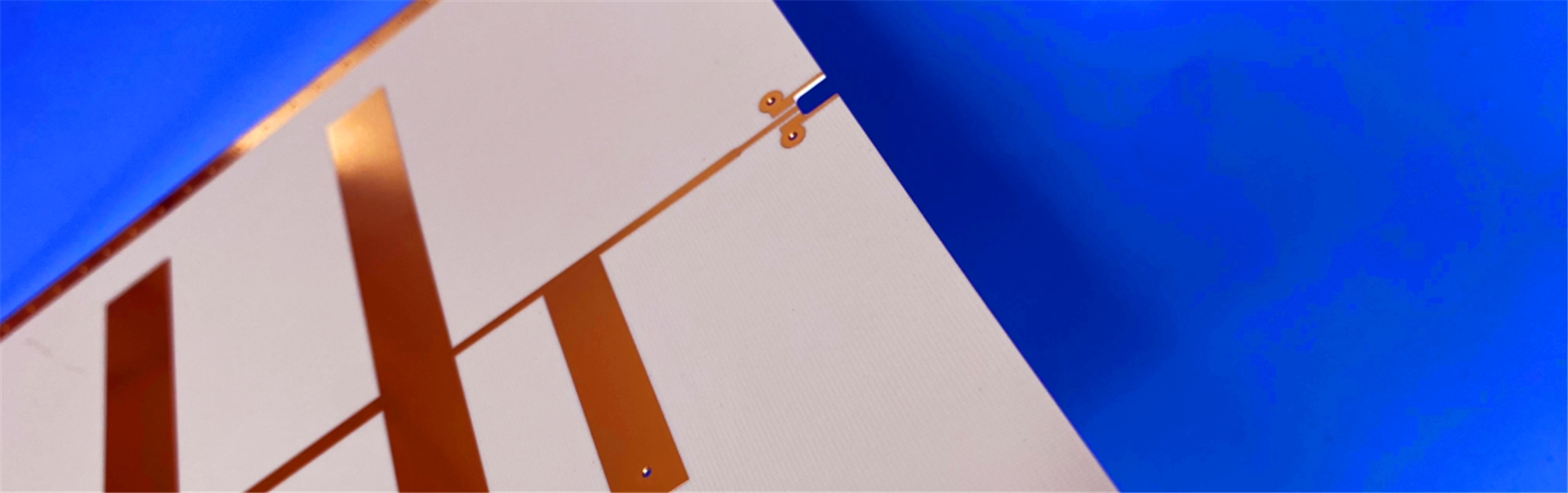

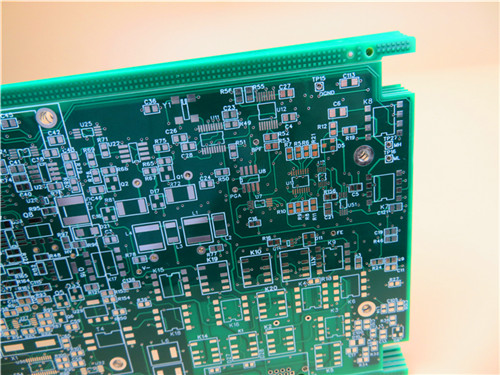

6-Layer S1000-2M PCB HDI Printed Circuit Board 90 Ohm Impedance Control HASL Finish

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

General Description

This high-performance 6-layer HDI PCB is manufactured using FR-4 S1000-2M material, known for its high Tg and low CTE properties. The board features controlled differential impedance configurations including 90 ohm on layer 3 with 6mil/7mil and 6mil/10mil trace/gap specifications, and layer 4 with 7mil/7mil and 6mil/7mil parameters. Constructed with 1oz copper on all layers, the board features HASL surface finish and green solder mask for reliable performance.

S1000-2M HDI PCB incorporates advanced via structures with blind vias from top layer to inner layer 4 and buried vias between inner layers 3 and 4. Manufactured to IPC-Class 2 standards, each board undergoes rigorous quality control and is supplied with V-cut scoring for easy separation. Packages contain 25 boards per shipment, ensuring consistent quality for volume production requirements.

Applications

Computers

Communications

Automotive electronics etc.

PCB Parameters

| PCB Parameters | ||||||||||||||||||||||||

| Item | Description | Requirement | Actual | Result | Hole Diameter Measurement (Unit: mm),Tolerance: PTH±0.075; NPTH±0.05 | |||||||||||||||||||

| 1. Laminate | Material Type | FR-4 S1000-2M | FR-4 S1000-2M | ACC | ||||||||||||||||||||

| Tg | 170℃ | 170℃ | ACC | Hole Code | PTH | Required | Actual value | Result | ||||||||||||||||

| Supplier | SHENGYI | SHENGYI | ACC | 1 | Y | 0.375 | 0.375 | 0.400 | 0.400 | 0.375 | ACC | |||||||||||||

| Thickness | 1.6±10% mm | 1.63-1.68mm | ACC | 2 | Y | 0.500 | 0.500 | 0.550 | 0.525 | 0.525 | ACC | |||||||||||||

| 2.Plating thickness | Hole Wall | ≥25µm | 30.17µm | ACC | 3 | Y | 0.7*2.4 | 0.7*2.4 | 0.7*2.41 | 0.69*2.4 | 0.7*2.4 | ACC | ||||||||||||

| Outer copper | 35µm | 41.09µm | ACC | 4 | Y | 0.625 | 0.625 | 0.600 | 0.625 | 0.600 | ACC | |||||||||||||

| Inner Copper | 30µm | 33.69µm | ACC | 5 | Y | 0.725 | 0.725 | 0.725 | 0.750 | 0.725 | ACC | |||||||||||||

| 3.Solder mask | Material Type | TAIYO/ PSR-2000GT600D | TAIYO/ PSR-2000GT600D | ACC | 6 | Y | 0.900 | 0.925 | 0.900 | 0.900 | 0.900 | ACC | ||||||||||||

| Color | Green | Green | ACC | 7 | Y | 1.000 | 1.000 | 0.950 | 0.975 | 1.000 | ACC | |||||||||||||

| Rigidity (Pencil Test) | ≥4H or above | 5H | ACC | 8 | N | 1.050 | 1.050 | 1.050 | 1.075 | 1.050 | ACC | |||||||||||||

| S/M Thickness | ≥10 µm | 20.11µm | ACC | 9 | Y | 1.300 | 1.300 | 1.300 | 1.325 | 1.325 | ACC | |||||||||||||

| Location | Both Sides | Both Sides | ACC | 10 | Y | 1.350 | 1.350 | 1.325 | 1.350 | 1.325 | ACC | |||||||||||||

| 4. Component Mark | Material Type | TAIYO/ IJR-4000 MW300 | IJR-4000 MW300 | ACC | 11 | Y | 1.575 | 1.575 | 1.600 | 1.600 | 1.575 | ACC | ||||||||||||

| Color | White | White | ACC | 12 | Y | 1.650 | 1.650 | 1.700 | 1.675 | 1.675 | ACC | |||||||||||||

| Location | C/S | C/S | ACC | 13 | Y | 1.700 | 1.700 | 1.750 | 1.725 | 1.725 | ACC | |||||||||||||

| 5.Vias | Through holes | Yes | L1-L6 | ACC | 14 | Y | 3.250 | 3.250 | 3.250 | 3.275 | 3.250 | ACC | ||||||||||||

| Blind vias | Yes | L1-L5 | ACC | 15 | Y | 3.450 | 3.450 | 3.400 | 3.425 | 3.450 | ACC | |||||||||||||

| Buried vias | Yes | L4-L5 | ACC | 16 | Y | 0.7*2.6 | 0.7*259 | 0.7*2.61 | 0.69*2.6 | 0.7*2.59 | ACC | |||||||||||||

| 6. Identification | UL Mark | YES | YES | ACC | ||||||||||||||||||||

| Date Code | WWYY | 0421 | ACC | |||||||||||||||||||||

| Mark Location | Solder Side | Solder Side | ACC | |||||||||||||||||||||

| 7. Surface Finish | Method | HASL Lead Free | HASL Lead Free | ACC | ||||||||||||||||||||

| Tin Thickness | 3-6µm | 4.06µm | ACC | |||||||||||||||||||||

| Nickel Thickness | ||||||||||||||||||||||||

| Gold Thickness | Impedance Test Report | |||||||||||||||||||||||

| 8. Normativeness | RoHS | Directive 2015/863/EU | OK | ACC | Sample NO. | Layer | Line Width(mil)±10% | Line Space (mil)±10% | Impedance Type | Required Value (ohm) | Tolerance | Actual Value | Result | |||||||||||

| REACH | Directive 1907 /2006 | OK | ACC | Single End | Differential | |||||||||||||||||||

| 9.Annular Ring | Min. Line Width (mil) | 6mil | 5.8mil | ACC | 1 | L3 | 6.000 | 7.000 | V | 90.00 | ±10% | 93.59 | ACC | |||||||||||

| Min. Spacing (mil) | 5mil | 5.2mil | ACC | L3 | 6.000 | 10.000 | V | 100.00 | ±10% | 102.33 | ACC | |||||||||||||

| 10.V-groove | Angle | 30° | 30° | ACC | L4 | 7.000 | 7.000 | V | 90.00 | ±10% | 88.99 | ACC | ||||||||||||

| Residual thickness | 0.5mm | 0.5mm | ACC | L4 | 6.000 | 7.000 | V | 90.00 | ±10% | 90.76 | ACC | |||||||||||||

| 11. Beveling | Angle | |||||||||||||||||||||||

| Height | ||||||||||||||||||||||||

| 12. Function | Electrical Test | 100% PASS | 100% PASS | ACC | ||||||||||||||||||||

| 13. Appearance | IPC Class Level | IPC-A-600J &6012D Class 2 | IPC-A-600J &6012D Class 2 | ACC | ||||||||||||||||||||

| Visual Inspection | IPC-A-600J &6012D Class 2 | IPC-A-600J &6012D Class 2 | ACC | |||||||||||||||||||||

| Warp and Twist | ≦0.7% | 0.21% | ACC | |||||||||||||||||||||

| 14. Reliability Test | Tape Test | No Peeling | OK | ACC | ||||||||||||||||||||

| Solvent Test | No Peeling | OK | ACC | |||||||||||||||||||||

| Solderability Test | 265 ±5℃ | OK | ACC | |||||||||||||||||||||

| Thermal Stress Test | 288 ±5℃ | OK | ACC | |||||||||||||||||||||

| Ionic Contamination Test | ≦ 1.56 µg/c㎡ | 0.56µg/c㎡ | ACC |