Home

-

Standard PCB

-

4-Layer 1.2mm High-Tg FR-4 TU-768 HDI PCB Coating Immersion Gold for Consumer Electronics and Automotive

Home

-

Standard PCB

-

4-Layer 1.2mm High-Tg FR-4 TU-768 HDI PCB Coating Immersion Gold for Consumer Electronics and Automotive

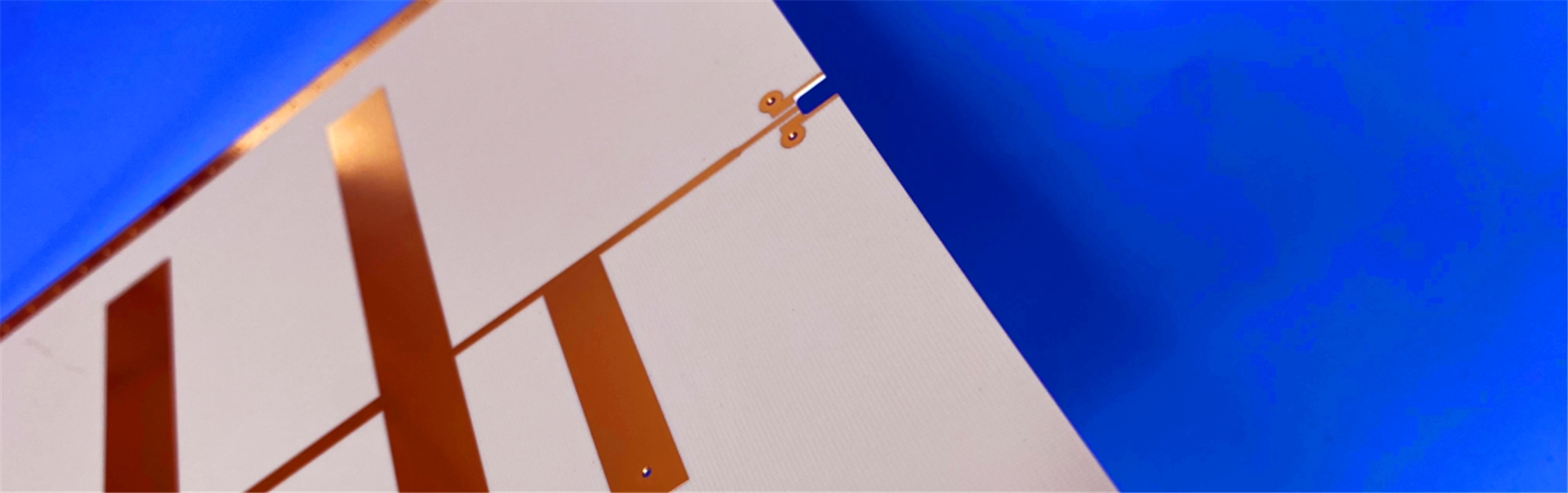

4-Layer 1.2mm High-Tg FR-4 TU-768 HDI PCB Coating Immersion Gold for Consumer Electronics and Automotive

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

Brief Introduction

This high-performance 4-layer PCB is engineered for applications demanding superior reliability and dense circuitry. Fabricated on robust TU-768 High-Tg base material, it ensures exceptional thermal stability. TU-768 PCB board features a sophisticated High-Density Interconnection (HDI) design, incorporating both blind vias from inner layer 2 to the bottom side and buried vias between inner layers 2 and 3, enabling complex routing in a compact structure.

Each layer is plated with 1oz copper for consistent conductivity, while the surface is finished with immersion gold on soldering pads for excellent solderability and a green solder mask on non-pad areas for protection. The standard build utilizes a 0.8mm thick core, resulting in a final finished PCB thickness of 1.6mm. For efficient production, the boards are typically panelized as 16-up arrays on a 320mm x 280mm panel. Guaranteeing the highest level of quality and reliability, every board is strictly fabricated to IPC-Class-3 standards and undergoes 100% electrical testing prior to shipment.

.jpg)

PCB Specifications

| Item | Description | Requirement | Actual | Result |

| 1. Laminate | Material Type | FR-4 TU-768 | FR-4 TU-768 | ACC |

| Tg | 170℃ | 170℃ | ACC | |

| Supplier | Taiwan Union (TU) | Taiwan Union (TU) | ACC | |

| Thickness | 1.2±10% mm | 1.18-1.21mm | ACC | |

| 2.Plating thickness | Hole Wall | ≥25µm | 26.15µm | ACC |

| Outer copper | 35µm | 37.85µm | ACC | |

| Inner Copper | 30µm | 31.15µm | ACC | |

| 3.Solder mask | Material Type | TAIYO/ PSR-2000GT600D | PSR-2000GT600D | ACC |

| Color | Green | Green | ACC | |

| Rigidity (Pencil Test) | ≥4H or above | 5H | ACC | |

| S/M Thickness | ≥10µm | 19.55µm | ACC | |

| Location | Both Sides | Both Sides | ACC | |

| 4. Component Mark | Material Type | TAIYO/ IJR-4000 MW300 | IJR-4000 MW300 | ACC |

| Color | White | White | ACC | |

| Location | C/S, S/S | C/S, S/S | ACC | |

| 5. Vias | Through holes | Yes | L1-L4 | ACC |

| Blind vias | Yes | L3-L4 | ACC | |

| Buried vias | Yes | L2-L3 | ACC | |

| 6. Identification | UL Mark | YES | YES | ACC |

| Date Code | WWYY | 0421 | ACC | |

| Mark Location | Solder Side | Solder Side | ACC | |

| 7. Surface Finish | Method | Immersion Gold | Immersion Gold | ACC |

| Tin Thickness | ||||

| Nickel Thickness | 3-6µm | 5.27µm | ACC | |

| Gold Thickness | 0.05µm | 0.065µm | ACC | |

| 8. Normativeness | RoHS | Directive 2015/863/EU | OK | ACC |

| REACH | Directive 1907 /2006 | OK | ACC | |

| 9.Annular Ring | Min. Line Width (mil) | 6mil | 5.8mil | ACC |

| Min. Spacing (mil) | 5mil | 5.2mil | ACC | |

| 10.V-groove | Angle | 30±5º | 30º | ACC |

| Residual thickness | 0.4±0.1mm | 0.39mm | ACC | |

| 11. Beveling | Angle | |||

| Height | ||||

| 12. Function | Electrical Test | 100% PASS | 100% PASS | ACC |

| 13. Appearance | IPC Class Level | IPC-A-600J &6012D Class 2 | IPC-A-600J &6012D Class 2 | ACC |

| Visual Inspection | IPC-A-600J &6012D Class 2 | IPC-A-600J &6012D Class 2 | ACC | |

| Warp and Twist | ≦0.7% | 0.32% | ACC | |

| 14. Reliability Test | Tape Test | No Peeling | OK | ACC |

| Solvent Test | No Peeling | OK | ACC | |

| Solderability Test | 265 ±5℃ | OK | ACC | |

| Thermal Stress Test | 288 ±5℃ | OK | ACC | |

| Ionic Contamination Test | ≦ 1.56 µg/c㎡ | 0.58µg/c㎡ | ACC |

Main Applications

Consumer Electronics

Server, workstation

Automotive

Our Advantages

ISO9001, ISO14001, IATF16949, ISO13485, UL Certified;

16000㎡ workshop;

30000㎡ output capability per month;

Prototype to large volume production capability

IPC Class 2 / IPC Class 3;

Any layer HDI PCBs;

Delivery on time: >98%

Customer complaint rate: <1%

Our PCB Capability (2025)

| Factory Process Capability (2025) | |

| Substrate Types | Standard FR-4, High Tg FR-4, High Frequency Materials, Rigid Polyimide, Flexible Polyimide, Transparent PET Materials, AL2O3 Ceramic, AlN Ceramic etc. |

| Substrate Brands | Shengyi, ITEQ, KB, Isola, Taiwan Union, Rogers Corp. Taconic, Wangling, Panasonic etc |

| Board Types | Rigid PCB, Flexible Circuits, Rigid-Flex PCB, Hybrid PCB, HDI PCB, Heavy Copper, High Speed, High frequency etc. |

| Copper Clad Laminates(CCL) | High Tg FR-4: S1000-2M, TU-872 SLK, TU-768, TU-883, IT-180A, FR408HR, 370HR, High CTI FR-4: S1600L, ST115 High speed: M6 (R5775G Core / R-5670 Prepreg) |

| Rogers Corp: RO4350B, RO4003C, RO4725JXR, RO4730G3, RO4360G2, RO4533, RO4534, RO4535, RO4830, RO4835, RO3003, RO3006, RO3010, RO3035, RO3203, RO3210; RT/Duriod 5880; RT/Duriod 5870, RT/Duriod 6002, RT/duroid 6006, RT/Duroid 6010.2LM, RT/duroid 6035HTC; RT/duroid 5880LZ, RT/duroid 6202; TMM3, TMM4, TMM6, TMM10, TMM10i, TMM13i, Kappa 438; AD250C, AD255C, AD300D, AD350A, AD450, AD600, AD1000, TC350; TC600; DiClad 880, DiClad 870, DiClad 527; IsoClad 917, IsoClad 933; CLTE-XT, CLTE-AT, CLTE-MW; CuClad 217, CuClad 233, CuClad 250. | |

| Taconic: TLF-35; RF-35TC, RF-60A, RF-60TC, RF-35A2,RF-30, RF-35, RF-45, RF-10, TRF-45; TLX-0, TLX-6, TLX-7, TLX-8; TLX-9, TLY-3, TLY-5, TLY-5Z; CER-10; TSM-DS3 | |

| Wangling: F4BM217, F4BM220, F4BM233, F4BM245, F4BM255, F4BM265, F4BM275, F4BM294, F4BM300; F4BME217, F4BME220, F4BME233, F4BME245, F4BME255, F4BME265, F4BME275, F4BME294, F4BME300; F4BTM298, F4BTM300, F4BTM320, F4BTM350; F4BTME298, F4BTME300, F4BTME320, F4BTME350; TP300, TP440, TP600, TP615, TP960, TP1020, TP1100, TP1600, TP2000, TP2200, TP2500; TF300, TF440, TF600, TF960, TF1020, TF1600; F4BTMS220, F4BTMS233, F4BTMS255, F4BTMS265, F4BTMS294, F4BTMS300, F4BTMS350, F4BTMS430, F4BTMS450, F4BTMS615, F4BTMS1000; TFA294, TFA300, TFA615, TFA1020; WL-CT300, WL-CT330, WL-CT330Z, WL-CT338, WL-CT350, WL-CT440, WL-CT615. |

|

| Maximum Delivery Size | 1200mm x 572 mm |

| Minimum Finished Board Thickness | L≤2L: 0.15mm; 4L: 0.4mm |

| Maximum Finished Board Thickness | 10.0 mm |

| Blind Buried Holes (Non-crossing) | 0.1mm |

| Maximum Hole Aspect Ratio | 15:01 |

| Minimum Mechanical Drill Hole Diameter | 0.1 mm |

| Through-hole Tolerance | +/- 0.0762 mm |

| Press-fit Hole Tolerance | +/- 0.05mm |

| Non-plated Copper Hole Tolerance | +/- 0.05mm |

| Maximum Number of Layers | 32 |

| Internal and External Layer Maximum Copper Thickness | 12Oz |

| Minimum Drill Hole Tolerance | +/- 2mil |

| Minimum Layer-to-Layer Tolerance | +/- 3mil |

| Minimum Line Width/Spacing | 3mil/3mil |

| Minimum BGA Diameter | 8mil |

| Impedance Tolerance | < 50Ω ±5Ω; ≥50Ω±10% |

| Special Technology | High density interconnection (HDI), Hybrid design/ mixed PCB, Blind/Buried vias, Resin filled / copper filled and capped, Copper coin embedded, Staircase PCB, Edge plated PCB, Heavy copper PCB, Half holes/castled Edge holes, Thick PCB etc |

| Surface Treatment Processes | Leaded/Lead-free HASL, Immersion Gold, Immersion Silver, Immersion Tin, OSP, ENIG, ENEPIG, Pure gold, Carbon Ink, Peelable Mask, Gold Finger, etc. |