Home

-

Rogers PCB

-

Rogers DiClad 527 PCB: Stable Dk and Low Loss 0.0018 for Radar and Base Station Antennas

Home

-

Rogers PCB

-

Rogers DiClad 527 PCB: Stable Dk and Low Loss 0.0018 for Radar and Base Station Antennas

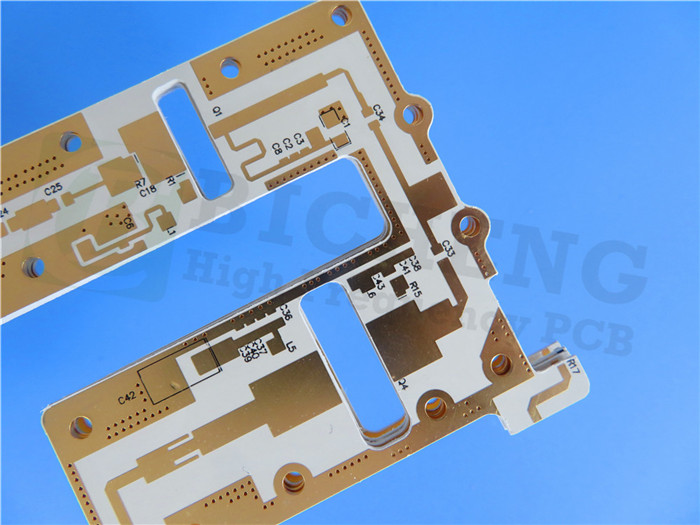

Rogers DiClad 527 PCB: Stable Dk and Low Loss 0.0018 for Radar and Base Station Antennas

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

General Description

Rogers DiClad 527 PCBs are fiberglass-woven reinforced composite materials, specifically engineered to serve as substrates for printed circuit boards.

Compared to pure PTFE-based materials, DiClad 527 laminates feature a higher proportion of fiberglass reinforcement relative to PTFE content. This precisely balanced composition not only enables a broader range of adjustable dielectric constant (Dk) values but also enhances two critical performance attributes: superior dimensional stability and more accurate registration during PCB manufacturing.

Standard Panel Sizes for DiClad 527:

18" x 12" (457 x 305mm)

18" x 24" (457 x 610mm)

Standard Thicknesses for DiClad 527:

0.020" (0.508mm) with a tolerance of +/- 0.0020"

0.030" (0.762mm) with a tolerance of +/- 0.0020"

0.060" (1.524mm) with a tolerance of +/- 0.0020"

Standard Claddings for DiClad 527:

Electrodeposited Copper Foil

1/2 oz. (18µm)

1 oz. (35µm)

For information on other available PCB configurations, such as additional thicknesses, panel sizes, and claddings, please contact our Customer Service or Sales Engineering teams.

Key Features:

- Dk range: 2.40 to 2.60

- Low dissipation factor: .0018 at 10GHz

- Low moisture absorption

Key Benefits:

- Stable Dk across a wide frequency range

- Low circuit losses at high frequencies

- Minimal performance variation in high humidity environments

- Excellent dimensional stability

- Consistent product performance

- Uniform electrical properties across frequencies

- Reliable mechanical performance

- Excellent chemical resistance

Our PCB Capability (DiClad 527)

PCB Capability (DiClad 527) |

|

PCB Material: |

Woven Fiberglass/PTFE composite |

Designation: |

DiClad 527 |

Dielectric constant: |

2.40-2.60 10GHz/23˚C |

Dissipation factor |

0.0017 10GHz/23˚C |

Layer count: |

Single Sided, Double Sided, Multi-layer PCB, Hybrid PCB |

Copper weight: |

1oz (35µm), 2oz (70µm) |

Dielectric thickness |

20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Immersion gold, HASL, Immersion silver, Immersion tin, ENEPIG, OSP, Bare copper, Pure gold etc.. |

Typical Applications:

- Radar feed networks

- Commercial phased array networks

- Low-loss base station antennas

- Guidance systems

- Digital radio antennas

- Filters, couplers, and LNAs

DiClad 527 Data Sheet

| Typical Value | |||||||

| Properties | DiClad 527 | Units | Test Conditions | Test Method | |||

| Electrical Properties | |||||||

| Dielectric Constant | 2.40-2.60 | - | 23˚C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 | ||

| Dielectric Constant | 2.40-2.60 | - | 23˚C @ 50% RH | 1 MHz | IPC TM-650 2.5.5.3 | ||

| Dissapation Factor | 0.0017 | 23˚C @ 50% RH | 10 GHz | IPC TM-650 2.5.5.5 | |||

| Dissapation Factor | 0.0010 | 23˚C @ 50% RH | 1 MHz | IPC TM-650 2.5.5.3 | |||

| Thermal Coefficient of Dielectric Constant |

-153 | ppm/˚C | -10 to 140˚C | 10 GHz | IPC TM-650 2.5.5.5 | ||

| Volume Resistivity | 1.2 x 109 | MΩ-cm | C96/35/90 | - | IPC TM-650 2.5.17.1 | ||

| Surface Resistivity | 4.5 x 107 | MΩ | C96/35/90 | - | IPC TM-650 2.5.17.1 | ||

| Dielectric Breakdown | >45 | kV | D48/50 | - | ASTM D-149 | ||

| Arc Resistance |

>180 | - | - | ASTM D-495 | |||

| Thermal Properties | |||||||

| Coefficient of Thermal Expansion - x | 14 | ppm/˚C | - | 50˚C to 150˚C | IPC TM-650 2.4.41 | ||

| Coefficient of Thermal Expansion - y | 21 | ppm/˚C | - | 50˚C to 150˚C | IPC TM-650 2.4.41 | ||

| Coefficient of Thermal Expansion - z | 173 | ppm/˚C | - | 50˚C to 150˚C | IPC TM-650 2.4.24 | ||

| Thermal Conductivity |

0.26 | W/(m.K) | ASTM E1461 | ||||

| Mechanical Properties | |||||||

| Copper Peel Strength | 14 | Lbs/in | 10s @288˚C | 35 μm foil | IPC TM-650 2.4.8 | ||

| Young’s Modulus | 517, 706 | kpsi | 23˚C @ 50% RH | - | ASTM D-638 | ||

| Tensile Strength (MD, CMD) | 19.0, 15.0 | kpsi | 23˚C @ 50% RH | - | ASTM D-882 | ||

| Compressive Modulus | 359 | kpsi | 23˚C @ 50% RH | - | ASTM D-695 | ||

| Flex Modulus |

537 | kpsi | 23˚C @ 50% RH | ASTM D-3039 | |||

| Physical Properties | |||||||

| Flammability | V-0 | C48/23/50 & C168/70 |

UL 94 | ||||

| Moisture Absorption | 0.03 | 0 | E1/105+D24/23 | IPC TM-650 2.6.2.2 | |||

| Density | 231 | g/cm³ | C24/23/50 | Method A | ASTM D792 | ||

| NASA Outgassing |

Total Mass Lost | 0.02 | 0 | 125°C, ≤ 10-6 torr | NASA SP-R-0022A | ||

| Collected Volatiles | 0.00 | 0 | |||||

| Water Vapor Recovered | 0.01 | 0 | |||||