Home

-

RF PCB

-

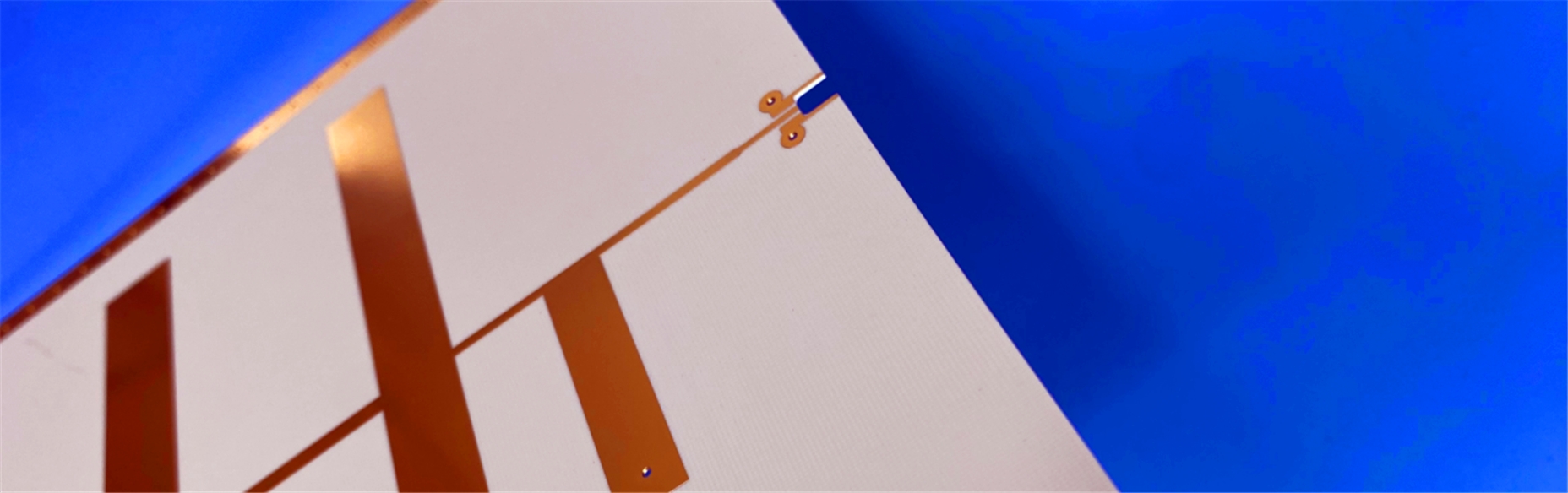

Shengyi SCGA-500 GF265 High Frequency PCB -- Made with Glass-Reinforced PTFE RF Circuit Materials for RF Applications

Home

-

RF PCB

-

Shengyi SCGA-500 GF265 High Frequency PCB -- Made with Glass-Reinforced PTFE RF Circuit Materials for RF Applications

Shengyi SCGA-500 GF265 High Frequency PCB -- Made with Glass-Reinforced PTFE RF Circuit Materials for RF Applications

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

General Description

The SCGA - 500 GF265 PCB, developed by Shengyi Technology Co., Ltd. (SYTECH), is a high - frequency circuit material that combines the benefits of low - loss PTFE and woven glass. With a UL 94 V - 0 fire rating, it is engineered to meet the exacting demands of today’s most challenging RF/Microwave design environments.

This SCGA - 500 GF265 material stands out for its precisely controlled dielectric constant, which enables it to deliver outstanding electrical and mechanical performance. Across a broad frequency spectrum from 1GHz to 20GHz and a wide temperature range of - 40°C to +125°C, SCGA - 500 GF265 PCB maintains a consistent and stable dielectric constant (DK) of 2.55 ± 0.04 and a dissipation factor of 0.0014.

In addition to its electrical prowess, the SCGA - 500 GF265 laminate offers remarkable physical properties. It demonstrates excellent dimensional stability, ensuring that components fabricated from it retain their shape and functionality under various conditions. GF265 RF PCB also boasts high chemical resistance, low moisture absorption, and strong copper peel strength, all of which contribute to its durability and reliability. Regarding passive inter - modulation (PIM) performance, typical values of - 163 dBc can be achieved when using RTF and VLP type copper foils.

For high - volume manufacturing scenarios where achieving the right balance between cost - effectiveness and performance is crucial, the SCGA - 500 GF265 PCB proves to be an ideal option. It provides manufacturers with a reliable and efficient solution that doesn't compromise on quality, making it a top pick in the industry for a wide array of applications.

.jpg)

Features

- Consistent and Stable Dk/Df over Frequency and Temperature

- Low Dielectric Loss Tangent

- Excellent Price Performance Value

Typical applications

- Base Station Antennas

- Power Amplifiers

- Satellite Communications

- DAS and CPE Antenna

- Automotive Radar and Wireless Communications.

PCB Capability(SCGA-500 GF265)

PCB Capability (SCGA-500 GF265) |

|

PCB Material: |

PTFE Woven Glass |

Designation: |

SCGA-500 GF265 |

Dielectric constant: |

2.65 (10 GHz) |

Dissipation factor |

0.0017 (10 GHz) |

Layer count: |

Double Sided PCB, Multilayer PCB, Hybrid PCB |

Copper weight: |

1oz (35µm), 2oz (70µm) |

Dielectric thickness |

10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 40mil (1.016mm), 50mil (1.270mm), 60mil (1.524mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Immersion gold ( ENIG), HASL, Immersion silver, Immersion tin, ENEPIG, OSP, Bare copper, Pure gold plated etc.. |

.jpg)

Our Advantages

- Powerful PCB capabilities support your research and development, sales and marketing;

- PCB Products and Manufacturing are certified by authorized organizations;

- 16000㎡ workshop with 30000㎡ output capability and 8000 types of PCB's per month;

- Quick CADCAM checking and free PCB quotation;

- No minimum order quantity. 1 piece is available;

- A Team with passion, discipline, responsibility and honesty;

- More than 19+ years of high frequency PCB experience;

- Prototype PCB capability to Volume Production capability;

- Delivery on time: >98%, Customer complaint rate: <1%

- IPC Class 2 / IPC Class 3;

Appendix: General Properties of SCGA-500

| SCGA-500 General Properties | |||||||

| Items | Typical Value GF220 | Typical Value GF255 | Typical Value GF265 | Typical Value GF300 | Unit | Method | Test Condition |

| Dielectric Constant | 2.2±0.02 | 2.55±0.04 | 2.65±0.04 | 3.00±0.04 | - | IPC-TM-650 2.5.5.5 | 10GHz/23℃ |

| Process Dk | |||||||

| Dissipation factor (Loss Tangent) | 0.0009 | 0.0014 | 0.0017 | 0.0023 | - | IPC-TM-650 2.5.5.5 | 10GHz/23℃ |

| TcDK | -110 | -70 | -60 | -25 | ppm/℃ | IEC 61189-2-721 | 10GHz (-40-150℃) |

| CTE (X/Y/Z-axis) | 41/30/217 | 8.2/7.9/145 | 9.2/8.8/118 | 6.2/8.6/95 | ppm/℃ | IPC-TM-650 2.4.24 | TMA (30-260℃) |

| Volume Resistivity | 1.5*108 | 1.5*108 | 1.2*108 | 1.3*108 | MΩ·cm | IPC-TM-650 2.5.17.1 | A |

| Surface Resistivity | 8.8*107 | 1.6*108 | 1.3*108 | 1.4*108 | MΩ | IPC-TM-650 2.5.17.1 | A |

| Peel Strength | 1.2 [6.86] | 1.2 [6.86] | 1.2 [6.86] | 1.2 [6.86] | N/mm [lb/in] | IPC-TM-650 2.4.8 | 288℃/10s |

| Water Absorption | 0.007 | 0.007 | 0.007 | 0.01 | % | IPC-TM-650 2.6.2.1 | D-24/23 |

| Thermal Conductivity | 0.27 | 0.29 | 0.28 | 0.28 | W/(m·K) | ASTM C518 | 100℃ |

| Tensile Modulus (LW/CW) | 1.9/2.6 | 1.27/7.8 | 1.9/6.8 | 7.9/8.8 | GPa | IPC-TM-650 2.4.4 | A |

| Tensile Strength (LW/CW) | 60/76 | 64/214 | 60/212 | 254/279 | MPa | IPC-TM-650 2.4.4 | A |

| Density | 2.18 | 2.25 | 2.22 | 2.27 | g/cm3 | ASTM D792 | - |

| Flammability | V-0 | V-0 | V-0 | V-0 | Rating | UL-94 | C-48/23/50 |