Home

-

RF PCB

-

Rogers RO4835 High Frequency PCB 10mil 20mil 30mil ED Copper 10.7mil 20.7mil 30.7mil LoPro Copper PCB

Home

-

RF PCB

-

Rogers RO4835 High Frequency PCB 10mil 20mil 30mil ED Copper 10.7mil 20.7mil 30.7mil LoPro Copper PCB

Rogers RO4835 High Frequency PCB 10mil 20mil 30mil ED Copper 10.7mil 20.7mil 30.7mil LoPro Copper PCB

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

Introduction

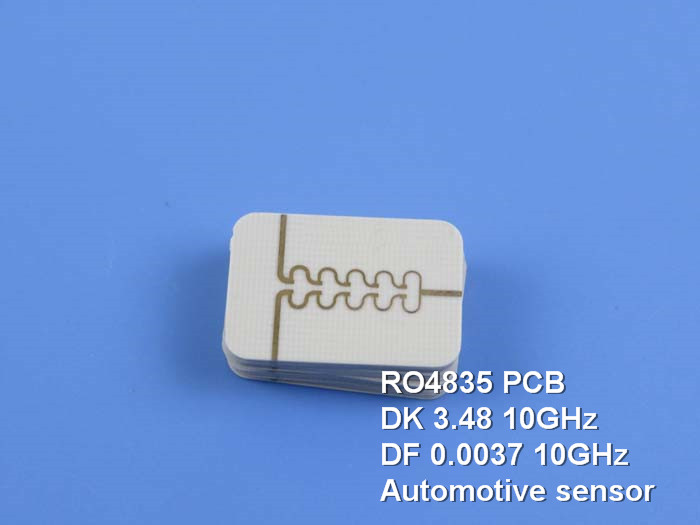

Rogers RO4835 PCBs, crafted as hydrocarbon ceramic laminates, stand out as antioxidative high-frequency materials engineered for peak stability in elevated-temperature environments. Unlike other hydrocarbon-based alternatives, RO4835 PCB exhibits remarkable oxidation resistance, safeguarding performance over time. Tailored to blend superior high-frequency capabilities with cost-effective circuit fabrication, RO4835 laminates offer a winning combination for diverse applications. Their electrical and mechanical attributes closely mirror those of the trusted RO4350B substrates, ensuring a seamless transition for long-time users.

Crucially, oxidation poses a threat to all thermoset laminate materials, with prolonged exposure to heat causing gradual increases in a circuit substrate's dielectric constant and dissipation factor. RO4835 PCB 's enhanced resistance to oxidation makes it a prime choice for applications where maintaining consistent performance under challenging conditions is non-negotiable.

Features and Benefits

1. Significantly improved oxidation resistance compared to typical thermoset microwave materials, which are designed for performance sensitive, high volume applications.

2. Low loss exhibits excellent electrical performance allowing application with higher operating frequencies, especially ideal for automotive applications.

3. Tight dielectric constant tolerance results in controlled impedance transmission lines

4. Lead-free process compatible results in no blistering or delamination

5. Low Z-axis expansion results in reliable plated through holes

6. Low in-plane expansion coefficient remains stable over an entire range of circuit processing temperatures

7. CAF resistant

Our PCB Capability (RO4835 PCB)

PCB Capability (RO4835) |

|

PCB Material: |

Hydrocarbon Ceramic Laminates |

Designation: |

RO4835 |

Dielectric constant: |

3.48 (10 GHz) |

Dissipation Factor |

0.0037 (10 GHz) |

Layer count: |

Single Sided PCB, Double Sided PCB, Multilayer PCB, Hybrid PCB |

Copper weight: |

1oz (35µm), 2oz (70µm) |

Dielectric thickness (ED copper) |

6.6mil (0.168mm), 10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm) |

Dielectric thickness (LoPro copper) |

4mil (0.102mm), 7.3mil (0.186mm), 10.7mil (0.272mm), 20.7mil (0.526mm), 30.7mil (0.780mm), 60.7mil (1.542mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, Immersion gold, Immersion silver, Immersion tin, ENEPIG, OSP, Pure gold plated etc.. |

Typical Applications

1. Automotive Radar and Sensors

2. Point-to point Microwave

3. Power Amplifiers

4. Phased - Array Radar

5. RF Components

Appendix: Typical Values of RO4835

| Property | RO4835 | Direction | Units | Condition | Test Method |

| Dielectric Constant,εProcess | 3.48±0.05 | Z | - | 10 GHz/23℃ | IPC-TM-650 2.5.5.5 Clamped Stripline |

| Dielectric Constant,εDesign | 3.66 | Z | - | 8 to 40 GHz | Differential Phase Length Method |

| Dissipation Factortan,δ | 0.0037 | Z | - | 10 GHz/23℃ | IPC-TM-650 2.5.5.5 |

| Thermal Coefficient of ε | +50 | Z | ppm/℃ | -100℃to 150℃ | IPC-TM-650 2.5.5.5 |

| Volume Resistivity | 5 x 108 | MΩ.cm | COND A | IPC-TM-650 2.5.17.1 | |

| Surface Resistivity | 7 x108 | MΩ | COND A | IPC-TM-650 2.5.17.1 | |

| Electrical Strength | 30.2(755) | Z | Kv/mm(v/mil) | IPC-TM-650 2.5.6.2 | |

| Tensile Modulus | 7780(1128) | Y | MPa(ksi) | RT | ASTM D 638 |

| Tensile Strength | 136(19.7) | Y | MPa(ksi) | RT | ASTM D 638 |

| Flexural Strength | 186 (27) | Mpa (kpsi) | IPC-TM-650 2.4.4 | ||

| Dimensional Stability | <0.5 | X,Y | mm/m (mils/inch) |

after etch+E2/150℃ | IPC-TM-650 2.4.39A |

| Coefficient of Thermal Expansion | 10 12 31 |

X Y Z |

ppm/℃ | -55℃to288℃ | IPC-TM-650 2.4.41 |

| Tg | >280 | ℃ TMA | A | IPC-TM-650 2.4.24.3 | |

| Td | 390 | ℃ TGA | ASTM D 3850 | ||

| Thermal Conductivity | 0.66 | W/m/oK | 80℃ | ASTM C518 | |

| Moisture Absorption | 0.05 | % | 48hrs immersion 0.060" | ||

| sample Temperature 50℃" | ASTM D 570 | ||||

| Density | 1.92 | gm/cm3 | 23℃ | ASTM D 792 | |

| Copper Peel Stength | 0.88 (5.0) | N/mm (pli) | after solder float 1 oz. EDC Foil |

IPC-TM-650 2.4.8 | |

| Flammability | V-0 | UL 94 | |||

| Lead-free Process Compatible | Yes |