Home

-

Prototype PCB

-

Taconic TLY-5Z High Frequency PCB 60mil 30mil 20mil and 10mil RF PCB with Immersion Gold

Home

-

Prototype PCB

-

Taconic TLY-5Z High Frequency PCB 60mil 30mil 20mil and 10mil RF PCB with Immersion Gold

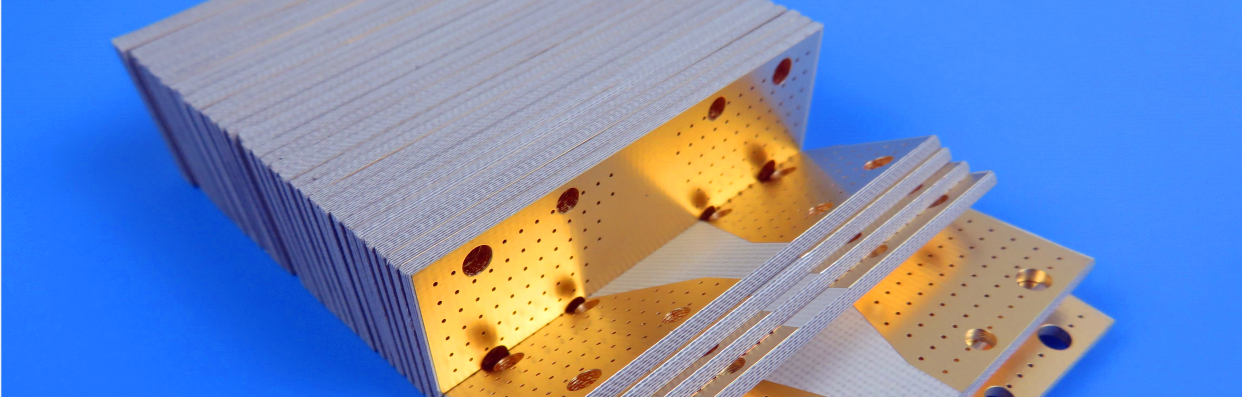

Taconic TLY-5Z High Frequency PCB 60mil 30mil 20mil and 10mil RF PCB with Immersion Gold

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

Introduction

Taconic TLY-5Z high-frequency PCBs are advanced composite materials engineered for demanding applications, particularly in aerospace where lightweight performance is critical. Combining ceramic, PTFE, and woven fiberglass reinforcement, TLY-5Z laminate achieves exceptional dimensional stability while maintaining a low-density profile. Its unique composition results in significantly reduced Z-axis expansion compared to traditional PTFE-rich composites, along with enhanced thermal stability—exhibiting just half the thermal expansion of standard PTFE laminates.Taconic TLY-5Z material's superior mechanical properties enable improved drilling performance and reliable operation through repeated thermal cycling, making it an optimal solution for high-frequency applications requiring both precision and durability.

.jpg)

Benefits of Taconic TLY-5Z PCB:

Low Z Axis CTE

Plated through hole stability

Low density (1.92 g/cm3)

Attractive price/performance ratio

Excellent peel strength

Compatible with flat copper

.jpg)

Typical Applications:

Aerospace components

Low weight antennas for aircraft

RF passive components

Our PCB Capability (TLY-5Z)

PCB Capability (TLY-5Z) |

|

PCB Material: |

Composites of Ceramic, PTFE and Woven Fiberglass |

Designation: |

TLY-5Z |

Dielectric constant: |

2.20 +/- 0.04 (10GHz) |

Dissipation Factor |

0.0015 (10GHz) |

Layer count: |

Single Sided, Double Sided PCB, Multilayer PCB, Hybrid PCB |

Copper weight: |

1oz (35 µm), 2oz (70µm) |

Laminate thickness: |

10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm ) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, ENEPIG, OSP, Pure gold plated etc.. |

About Us

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen China, severing cellular base station antenna, satellite, high frequency passive components, microstrip line and band line circuit, millimeter wave equipment, radar systems, digital radio frequency antenna and other fields worldwide for 20 years. Our high frequency PCBs are mainly built on 3 high frequency material brands: Rogers Corporation, Taconic and Wangling. Dielectric constant ranges from 2.2 to 10.2 etc.

We also have divisions of FR-4 circuit board, flexible circuits and metal core PCBs featured as prototypes, small runs to mass production. We also actively research and build such high value added PCB projects as HDI, quick turn, impedance control, heavy copper and backplane board etc. This has made our PCB products generate an effective prolongation and complementation, as well as formation of integrated products line ranging from low-end to high-end.

Our PCBs are used for a variety of purposes, including, but not limited to, computer networking, safety and surveillance, power supply, telecommunication, automotive electronics, medical apparatus and instruments, national defense and industrial equipment etc.

Appendix: Typical Values of TLY-5Z

| TLY-5Z Typical Values | |||||

| Property | Test Method | Unit | Value | Unit | Value |

| Dk @ 1.9 GHz | IPC-650 2.5.5.5.1 Mod. | 2.20+/- 0.04 | 2.20+/- 0.04 | ||

| Df @ 1.9 GHz | IPC-650 2.5.5.5.1 Mod. | 0.001 | 0.001 | ||

| Df @ 10 GHz | IPC-650 2.5.5.5.1 Mod. | 0.0015 | 0.0015 | ||

| Tc(D)K (-55 ~150°C) | IPC-650 2.5.5.6 Mod. | ppm/°C | -72 | ppm/°C | -72 |

| Dielectric Breakdown Voltage | IPC-650 2.5.6 | kV | 45 | kV | 45 |

| Dielectric Strength | IPC-650 2.5.6.2 | V/mil | 770 | V/mm | 30,315 |

| Moisture Absorption | IPC-650 2.6.2.1 | % | 0.03 | % | 0.03 |

| Peel Strength (1 oz. copper) | IPC-650 2.4.8 | lbs./inch | 7 | N/mm | 1.3 |

| Volume Resistivity | IPC-650 2.5.17.1 | Mohms/cm | 10^9 | Mohms/cm | 10^9 |

| Surface Resistivity | IPC-650 2.5.17.1 | Mohms | 10^8 | Mohms | 10^8 |

| Tensile Strength (MD) | IPC-650 2.4.18.3 | psi | 9137 | N/mm2 | 63 |

| Tensile Strength (CD) | IPC-650 2.4.18.3 | psi | 9572 | N/mm2 | 66 |

| Tensile Modulus (MD) | IPC-650 2.4.18.3 | psi | 182,748 | N/mm2 | 1260 |

| Tensile Modulus (CD) | IPC-650 2.4.18.3 | psi | 165,344 | N/mm2 | 1140 |

| Elongation (MD) | IPC-650 2.4.18.3 | % | 6 | % | 6 |

| Elongation (CD) | IPC-650 2.4.18.3 | % | 6.9 | % | 6.9 |

| Flex Strength (MD) | ASTM D790 | psi | 10,300 | N/mm2 | 71 |

| Flex Strength (CD) | ASTM D790 | psi | 11,600 | N/mm2 | 80 |

| Flex Modulus (MD) | ASTM D790 | psi | 377,100 | N/mm2 | 2600 |

| Flex Modulus (CD) | ASTM D790 | psi | 432,213 | N/mm2 | 2980 |

| Dimensional Stability (MD) | IPC-650 2.4.39 (Bake) | % (10 mil) | -0.05 | % (30 mil) | -0.05 |

| Dimensional Stability (CD) | IPC-650 2.4.39 (Bake) | % (10 mil) | -0.17 | % (30 mil) | -0.11 |

| Dimensional Stability (MD) | IPC-650 2.4.39 (Stress) | % (10 mil) | -0.07 | % (30 mil) | -0.07 |

| Dimensional Stability (CD) | IPC-650 2.4.39 (Stress) | % (10 mil) | -0.22 | % (30 mil) | -0.14 |

| Density (Specific Gravity) | IPC-650 2.3.5 | g/cm3 | 1.92 | g/cm3 | 1.92 |

| Specific Heat | IPC-650 2.4.50 | J/g°C | 0.95 | J/g°C | 0.95 |

| Thermal Conductivity | IPC-650 2.4.50 | W/M*K | 0.2 | W/M*K | 0.2 |

| CTE (x-y) (50 - 150°C) | IPC-650 2.4.41 | ppm/ºC | 30-40 | ppm/ºC | 30-40 |

| CTE (z) (50 - 150°C) | IPC-650 2.4.41 | ppm/ºC | 130 | ppm/ºC | 130 |

| Hardness | ASTM D2240 (Durometer) | - | 68 | - | 68 |

| UL-94 Flammability Rating | UL-94 | V-0 | V-0 |