.png)

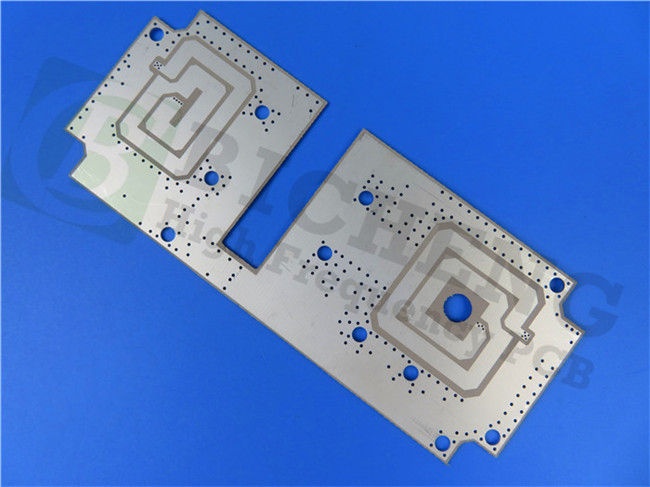

RT/duroid 6002 High Frequency PCB Material Introduction Hello everyone. Welcome back to our channel. Today, we are going to talk about the high frequency PCB made on RT/duroid 6002 material. Rogers RT/duroid 6002 high frequency PCB material is the preferred PTFE-based ceramic composites. It is a kind of low loss and low dielectric constant laminate, which can meet the strict requirements for mechanical reliability and electrical stability in complex microwave structural design. The dielectric constant of RT/duroid 6002 has excellent resistance to temperature change between -55 ℃ and 150 ℃, which can meet the requirements of filter, oscillator and delay line for its electrical stability. RT/duroid 6002 Typical Properties Rogers RT/duroid 6002 laminate is a truly impressive material, offering a range of properties that make it ideal for demanding applications. Let's take a closer look at some of its key features. First and foremost, let's talk about the Dielectric Constant of RT/duroid 6002. With a process value of 2.94±0.04 at 10 GHz and 23°C, it ensures reliable signal transmission. The Dielectric Constant in the design phase remains consistent at 2.94 across a frequency range of 8 GHz to 40 GHz, as determined using the Differential Phase Length Method. The Dissipation Factor, or tan delta, is impressively low at 0.0012 at 10 GHz and 23°C, indicating minimal signal loss and excellent performance. RT/duroid 6002 laminate also exhibits a positive thermal coefficient of dielectric constant, measuring +12 ppm/°C at 10 GHz over a temperature range of 0°C to 100°C. This ensures stability and reliable performance even in varying thermal conditions. Moving on to electrical properties, the volume resistivity of RT/duroid 6002 is 10^6 Mohm.cm, demonstrating excellent electrical insulation capabilities. Additionally, the surface resistivity measures 10^7 Mohm, further enhancing the material's electrical performance. In terms of mechanical properties, RT/duroid 6002 showcases impressive tensile modulus values of 828 MPa (120 kpsi) in both the X and Y directions at 23°C, indicating its high strength and rigidity. The material also exhibits an ultimate stress of 6.9 MPa (1.0 kpsi) and an ultimate strain of 7.3%, highlighting its ability to withstand demanding conditions. When it comes to compressive strength, RT/duroid 6002 boasts a compressive modulus of 2482 MPa (360 kpsi) in the Z direction, ensuring structural integrity under pressure. Rogers RT/duroid 6002 PCB has excellent resistance to moisture absorption, with only 0.02% absorption according to the D48/50 test method specified by IPC-TM-650 2.6.2.1 and ASTM D570. The material also exhibits a thermal conductivity of 0.6 W/m/K at 80°C, allowing for efficient heat dissipation in electronic systems. Other notable properties include a decomposition temperature (Td) of 500°C, ensuring the material's stability and reliability even at high temperatures. The density of RT/duroid 6002 is 2.1 gm/cm3, and its specific heat measures 0.93 J/g/K (0.22 BTU/ib/°F), contributing to efficient thermal management. Rogers RT/duroid 6002 PCB also exhibits excellent copper peel strength, with a value of 8.9 lbs/in (1.6 N/mm), as tested according to IPC-TM-650 2.4.8. Additionally, RT/duroid 6002 is classified as V-0 for flammability according to UL 94 standards, ensuring its resistance to ignition and flame propagation. Last but not least, RT/duroid 6002 is compatible with lead-free processes, aligning with industry standards and environmental regulations. Property RT/duroid 6002 Direction Units Condition Test Method Dielectric Constant,εProcess 2.94±0.04 Z 10 GHz/23℃ IPC-TM-650 2.5.5.5 Dielectric Constant,εDesign 2.94 8GHz to 40 GHz Differential Phase Length Method Dissipation Factor,tanδ 0.0012 Z 10 GHz/23℃ IPC-TM-650 2.5.5.5 Thermal Coefficient of ε +12 Z ppm/℃ 10 GHz 0℃-100℃ IPC-TM-650 2.5.5.5 Volume Resistivity 106 Z Mohm.cm A ASTM D 257 Surface Resistivity 107 Z Mohm A ASTM D 257 Tensile Modulus 828(120) X,Y MPa(kpsi) 23℃ ASTM D 638 Ultimate Stress 6.9(1.0) X,Y MPa(kpsi) Ultimate Strain 7.3 X,Y % Compressive Modulus 2482(360) Z MPa(kpsi) ASTM D 638 Moisture Absorption 0.02 % D48/50 IPC-TM-650 2.6.2.1 Thermal Conductivity 0.6 W/m/k 80℃ ASTM C518 Coefficient of Thermal Expansion 16 X ppm/℃ 23℃/50% RH IPC-TM-650 2.4.41 Td 500 ℃ TGA ASTM D 3850 Density 2.1 gm/cm3 ASTM D 792 Specific Heat 0.93(0.22) j/g/k Calculated Copper Peel 8.9(1.6) Ibs/in.(N/mm) IPC-TM-650 2.4.8 Flammability V-0 UL 94 Lead-free Process Compatible Yes PCB Capability (RT/duroid 6002) For RT/duroid 6002 PCBs, we can provide you with single layer board, double layer board, multi-layer board and hybrid types. RT/duroid 6002 PCBs have wide thickness. There are the standard thickness such as 10 mils, 20 mils, 30 mils and 60mils etc. and non-standard thickness such as 15 mils, 25 mils,35 mils and 40 mils etc. It’s as thin as 5 mils and as thick as 125 mils for our designers. Finished PCB copper has 1oz and 2oz. Our maximum PCB size on high frequency material is 400mm by 500mm, it can be a single board in the sheet and also can be different designs in this panel. Solder mask of green, black, blue and yellow etc is available in house. There’s immersion gold, HASL, immersion silver, immersion tin, bare copper etc. for pads plating. PCB material: Ceramic-filled PTFE composite Designation: RT/duroid 6002 Dielectric constant: 2.94 ±0.04 (process), 2.94 (design) Layer count: 1-layer, 2-layer, multi-layer, hybrid designs. Laminate thickness: 5mil (0.127mm), 10mil (0.254mm), 15mil (0.381mm), 20mil (0.508mm), 25mil (0.635mm), 30mil (0.762mm), 35mil (0.889mm), 40mil (1.016mm), 50mil (1.270mm), 60mil (1.524mm), 90mil (2.286mm), 100mil (2.540mm), 120mil (3.048mm), 125mil (3.175mm) Copper weight: 1oz (35µm), 2oz (70µm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Yellow, Red, etc. Surface finish: Immersion gold, HASL, Immersion silver, Immersion tin, Bare copper, OSP etc.. A Piece of RT/duroid 6002 PCB The basic colour of RT/duroid 6002 PCB is white. What we’re seeing on the screen is a type of double sided PCB with immersion silver for phased array antennas. We can also see its applications in GPS antennas, ground based and airborne radar systems, power backplanes and commercial airline collision avoidance etc. Conclusion Rogers RT/duroid 6002 PCB has tight thickness control with low out-gassing. It is very suited to the equipment of flat and non-planar structures, such as antennas, complex multi-layer PCBs with inner-layer connections, and microwave PCBs for aerospace designs in hostile environments. OK. This concludes today’s episode. Thank you for reading. See you next time.

ASTM D 570

(-55 to 288℃)

16

24

Y

Z

(BTU/ib/OF)