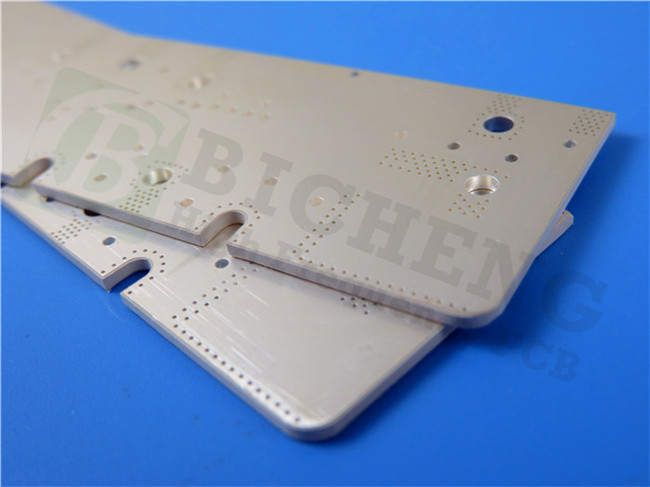

F4BM High Frequency PCB Material Introduction Welcome back to our channel. I am Ivy, the regional sales manager for Bicheng PCB. Today, we’re going to talk about high frequency PCB built on DiClad 880 substrates. DiClad 880 laminates are woven fiberglass reinforced, PTFE-based composites that offer lower dielectric constant (Dk) and dissipation factors (Df), which are frequently used in filter, coupler, and low noise amplifier applications, where dielectric constant uniformity is critical. They are also used in power dividers and combiners, where low loss is important. Let's now take a moment to delve deeper into the properties of DiClad 880. DiClad 880 Typical Properties Rogers DiClad 880 is woven fiberglass reinforced, PTFE-based material but does not contain any ceramic filler. Its dielectric constant is carefully adjusted through a precise mixing ratio of PTFE and fiberglass. By using fewer content of woven fiberglass and high ratio of PTFE, DiClad 880 achieves a lower DK value of 2.17 or 2.2 at 10 GHz, as well as a lower dissipation factor of 0.0009 @ 10 GHz. However, it is important to note that this material may have less dimensional stability than high DK materials. Moving on to the thermal properties, the thermal coefficient of dielectric constant (TCDk) of DiClad 880 is relatively poor at -160 ppm/°C due to the absence of any ceramic fillers. Furthermore, the coefficient of thermal expansion (CTE) in the Z-axis becomes higher at 252 ppm/°C, which results in weaker thermal conductivity of 0.26 W/mK. The peel strength measures at 14 lbs/inch after thermal stress, indicating a strong adhesion to copper. In addition, both the volume resistivity and surface resistivity are quite good, volume resistivity measuring at 1.4 x 10^9 MΩ-cm and surface resistivity measuring at 2.9 x 10^6 MΩ. and DiClad 880 material has an arc resistance of greater than 180 seconds. Rogers DiClad 880 PCB also performs exceptionally well in terms of tensile modulus, tensile strength, compressive modulus, and flexural modulus. The dielectric breakdown value is greater than 45 kilo voltage, and the material density is 2.23 g/cm³. It meets the requirements of UL94-V0 flammability standards and has low water absorption of 0.02%. DiClad 880 substrate has impressive outgassing properties. It has a low total mass loss of 0.01%, which is well within the maximum threshold of 1%. The collected volatile condensable material also has a maximum limit of 0.10% and a low value of 0.01%. Furthermore, it has a water vapor regain rate of 0.01%, indicating that it is resistant to water vapor absorption. There is also no visible condensate present, which means that the material does not release any visible condensate during use. These parameters demonstrate that DiClad 880 has excellent outgassing characteristics and is a highly stable and reliable material. Property DiClad 880 Condition Test Method Dielectric Constant 2.17, 2.20 @ 10 GHz C23/50 IPC TM-650 2.5.5.5 2.17, 2.20 @ 1 MHz C23/50 IPC TM-650 2.5.5.3 Dissipation Factor 0.0009 @ 10 GHz C23/50 IPC TM-650 2.5.5.5 0.0008 @ 1 MHz C23/50 IPC TM-650 2.5.5.3 Thermal Coefficient of Er (ppm/°C) -160 -10°C to +140°C IPC TM-650 2.5.5.5 Coefficient of Thermal Expansion (ppm/°C) 0°C to 100°C IPC TM-650 2.4.24 Mettler 3000 Thermomechanical Analyzer X Axis 25 Y Axis 34 Z Axis 252 Thermal Conductivity (W/mK) 0.261 100°C ASTM E-1225 Peel Strength (lbs.per inch) 14 After Thermal Stress IPC TM-650 2.4.8 Volume Resistivity (MΩ-cm) 1.4 x 10 9 C96/35/90 IPC TM-650 2.5.17.1 Surface Resistivity (MΩ) 2.9 x 10 6 C96/35/90 IPC TM-650 2.5.17.1 Arc Resistance >180 D48/50 ASTM D-495 Tensile Modulus (kpsi) 267, 202 A, 23°C ASTM D-638 Tensile Strength (kpsi) 8.1, 7.5 A, 23°C ASTM D-882 Compressive Modulus (kpsi) 237 A, 23°C ASTM D-695 Flexural Modulus (kpsi) 357 A, 23°C ASTM D-790 Dielectric Breakdown (kV) >45 D48/50 ASTM D-149 Density (g/cm3) 2.23 A, 23°C ASTM D-792 Method A Flammability Meets requirements of UL94-V0 C48/23/50, E24/125 UL 94 Vertical Burn IPC TM-650 2.3.10 Water Absorption (%) 0.02 E1/105 + D24/23 MIL-S-13949H 3.7.7 Outgassing 125°C, ≤ 10-6 torr NASA SP-R-0022A Total Mass Loss (%) 0.01 Maximum 1.00% Collected Volatile Condensable Material (%) 0.01 Maximum 0.10% Water Vapor Regain (%) 0.01 Visible Condensate (±) NO PCB Capability (DiClad 880) RTgers DiClad880 PCB is available in various layer counts, including single-sided, double-sided, multilayer, and hybrid PCBs, and it comes in different dielectric thicknesses of 20mil (0.508mm), 30mil (0.762mm), and 60mil (1.524mm). Additionally, it is available in copper weights of 1oz (35µm) and 2oz (70µm), which allows for flexibility in design. DiClad880 PCB size is limited to 400mm by 500mm, but it can be manufactured to fit various applications. The solder mask is available in a range of colors, such as green, black, blue, yellow, and red, among others. The surface finish of the DiClad 880 PCB is also customizable and available in different options, including immersion gold, hot air soldering level (HASL), immersion silver, immersion tin, bare copper, OSP, and pure gold plated, among others. PCB Material: Woven Fiberglass Reinforced, PTFE-based Composites Designation: DiClad 880 Dielectric constant: 2.20 ?(10 GHz) Dissipation factor: 0.0009 (10 GHz) Layer count: Single Sided, Double Sided, Multilayer PCB, Hybrid PCB Dielectric thickness: 20mil (0.508mm), 30mil (0.762mm), ?60mil (1.524mm) Copper weight: 1oz (35µm), 2oz (70µm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Yellow, Red etc. Surface finish: Immersoin gold, Hot air soldering level (HASL), Immersion silver, Immersion tin, Bare copper, OSP, Pure gold plated etc.. A Piece of DiClad 880 PCB Currently displayed on the screen is a 60mil DiClad 880 printed circuit board with immersion gold plating, designed specifically for digital radio antennas. Rogers Diclad880 PCBs are versatile and find utility in a variety of other applications as well, including radar feed networks, commercial phased array networks, low loss base station antennas, guidance systems, and more. Diclad880 PCBs are versatile and find utility in a variety of other applications as well, including radar feed networks, commercial phased array networks, low loss base station antennas, guidance systems, and more. Conclusion Rogers DiClad 880 material is compatible with both traditional electroless copper and direct deposit metallization processes. The standard equipment and chemical processes can be used to plate, image, and etch circuit patterns, making the fabrication process simple and convenient. Furthermore, most surface finishes such as HASL, tin, silver, Nickel/gold and OSP, etc.have been applied to DiClad 880 without any issue or special concern. That concludes today's episode. Thank you for reading. We look forward to seeing you again next time.

Adapted

IPC TM-650 2.6.2.2