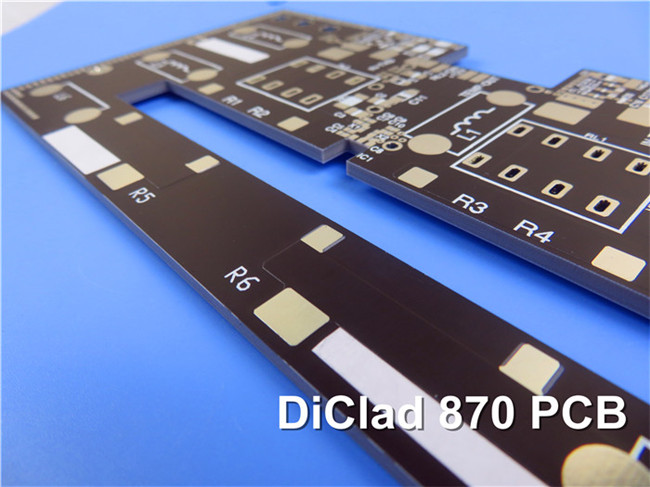

DiClad 870 High Frequency PCB Material Introduction Welcome back to our channel. My name is Jane, the regional sales manager for Bicheng PCB. In today’s video, we’ll be discussing a type of high frequency PCB that features a lower dielectric constant --- Rogers DiClad 870 microwave PCB. DiClad 870 is a type of Rogers laminate that is made with woven fiberglass reinforced, PTFE-based composites. This unique composition allows for a stable, lower dielectric constant by using fewer plies of woven fiberglass and a higher ratio of PTFE content. As a result, this material can support wider line widths for lower insertion loss. To learn more about DiClad 870 laminate, let’s see the data sheet. DiClad 870 Typical Properties DiClad 870 is a material that offers excellent electrical properties. It has a dielectric constant of 2.33 at both 1 MHz and 10 GHz, with a low dissipation factor of 0.0009 at 1 MHz and 0.0013 at 10 GHz. It also has a thermal coefficient of dielectric constant of -161 ppm/°C from -10°C to +140°C. DiClad 870 has a high volume resistivity of 1.5 x 10^9 MΩ-cm and a surface resistivity of 3.4 x 10^7 MΩ. Additionally, it shows an arc resistance of greater than 180 seconds, tested according to ASTM D-495 using the D48/50 method. This is an impressive result. DiClad 870 shows a dielectric breakdown voltage of greater than 45 kV, tested according to ASTM D-149 using the D48/50 method. This is another impressive result as well. When it comes to mechanical properties, DiClad 870 has a high peel strength of 14 lbs. per inch after thermal stress. It also has impressive tensile modulus, tensile strength, compressive modulus, and flexural modulus at 23°C. DiClad 870 also has great thermal properties. It has a low coefficient of thermal expansion of 17 ppm/°C (X axis), 29 ppm/°C (Y axis), and 217 ppm/°C (Z axis) from 0°C to 100°C. However, the thermal conductivity is only 0.257 W/mK at 100°C. It meets the requirements of UL94-V0 flammability rating, which makes it a safe material to use. A final aspect we'll examine is the physical properties. DiClad 870 shows a density of 2.26 g/cm3 at 23°C, tested according to ASTM D-792 Method A. This is a relatively high density, which suggests that DiClad 870 is a dense and sturdy material. Water absorption rate of 0.02% is low, indicating that DiClad 870 is a material that does not absorb water easily. Then, last one is outgassing characteristics. Outgassing refers to the release of volatile materials from a material during use. The data shows that DiClad 870 has minimal outgassing, with a total mass loss of 0.02%, collected volatile condensable material of 0.00%, and water vapor regain of 0.01% at 125°C and ≤ 10^-6 torr and there was no visible condensate. Property DiClad 870 Condition Test Method Electrical Properties Dielectric Constant @ 10 GHz 2.33 C23/50 IPC TM-650 2.5.5.5 Dielectric Constant @ 1 MHz 2.33 C23/50 IPC TM-650 2.5.5.3 Dissipation Factor @ 10 GHz 0.0013 C23/50 IPC TM-650 2.5.5.5 Dissipation Factor @ 1 MHz 0.0009 C23/50 IPC TM-650 2.5.5.3 Thermal Coefficient of Er (ppm/°C) -161 -10°C to +140°C IPC TM-650 2.5.5.5 Volume Resistivity (MΩ-cm) 1.5 x 10 9 C96/35/90 IPC TM-650 2.5.17.1 Surface Resistivity (MΩ) 3.4 x 10 7 C96/35/90 IPC TM-650 2.5.17.1 Arc Resistance >180 D48/50 ASTM D-495 Dielectric Breakdown (kV) >45 D48/50 ASTM D-149 Mechanical Properties Peel Strength (lbs.per inch) 14 After Thermal Stress IPC TM-650 2.4.8 Tensile Modulus (kpsi) 485(MD), 346(CD) A, 23°C ASTM D-638 Tensile Strength (kpsi) 14.9(MD), 11.2 (CD) A, 23°C ASTM D-882 Compressive Modulus (kpsi) 327 A, 23°C ASTM D-695 Flexural Modulus (kpsi) 437 A, 23°C ASTM D-790 Thermal Properties Coefficient of Thermal Expansion (ppm/°C) X Axis Y Axis Z Axis 17 29 ?217 0°C to 100°C IPC TM-650 2.4.24 Mettler 3000 Thermomechanical Analyzer Thermal Conductivity (W/mK) 0.257 100°C ASTM E-1225 Flammability UL Meets requirements of UL94-V0 C48/23/50, E24/125 UL 94 Vertical Burn IPC TM-650 2.3.10 Physical Properties Density (g/cm3) 2.26 A, 23°C ASTM D-792 Method A Water Absorption (%) 0.02 E1/105 + D24/23 MIL-S-13949H 3.7.7 Outgassing Total Mass Loss (%) Collected Volatile Condensable Material (%)Water Vapor Regain (%) Visible Condensate (±) 0.02 0.00 0.01 NO 125°C, ≤ 10-6 torr NASA SP-R-0022A Maximum 1.00% Maximum 0.10% Our PCB Capability (DiClad 870) We offer a variety of options for DiClad 870 PCBs, including single-sided, double-sided, multi-layer, and hybrid types. Rogers DiClad 870 PCBs are available in three commonly used thicknesses: 31 mils, 93 mils, and 125 mils. Finished copper on track lines can be either 1oz or 2oz. The maximum size for a DiClad 870 PCB is 400mm by 500mm, and it can be a single board or a panel with different designs. Solder mask of green, black, blue, red and yellow etc is available in house. Surface finishes on pads can be immersion gold, HASL, immersion silver, immersion tin, OSP, ENEPIG, pure gold and bare copper etc. PCB material: Woven Fiberglass reinforced PTFE Laminates Designation: DiClad 870 Dielectric constant: 2.3 Layer count: Sinlge-sided PCB, Double-sided PCB, Multi-layer PCB, Hybrid PCB Dielectric thickness: 31mil (0.787mm), 93mil (2.286mm), 125mil (3.175mm) Copper weight: 1oz (35µm), 2oz (70µm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Red, Yellow etc. Surface finish: Immersion gold, HASL, Immersion silver, Immersion tin, OSP, ENEPIG, Pure gold, Bare copper, etc.. A Piece of DiClad 870 PCB The screen displays a 0.8mm DiClad 870 PCB with hot air solder leveling, designed for digital radio antennas. This type of PCB is also commonly used in applications such as radar feed networks, commercial phased array networks, low loss base station antennas, and RF components like filters and couplers. Conclusion DiClad 870 materials are compatible with conventional electroless copper and direct deposit metallization processes, allowing for the use of standard equipment and chemical processes in the plating, imaging, and etching of circuit patterns on the material. That's all for today's episode. Thank you for reading and we'll see you next time.

Adapted

IPC TM-650 2.6.2.2