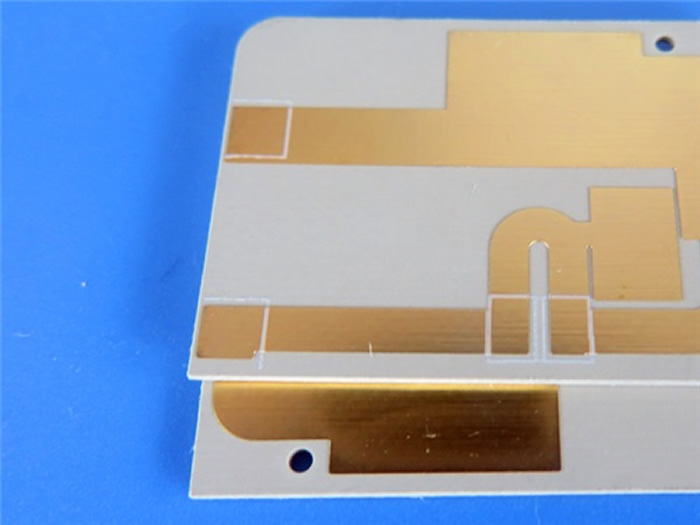

Rogers CuClad 233 High Frequency PCB Material Introduction Rogers CuClad® laminates are woven fiberglass/PTFE composite materials engineered as high-performance substrates for printed circuit boards. By precisely controlling the fiberglass-to-PTFE ratio, these laminates provide a selectable range of dielectric properties—from the industry’s lowest dielectric constant and loss tangent to more heavily reinforced versions offering superior dimensional stability. The woven fiberglass reinforcement ensures greater dimensional stability compared to non-woven PTFE laminates of similar dielectric values. Rogers’ controlled PTFE-coated glass cloth process enables a wider variety of dielectric constants and delivers exceptional dielectric uniformity across the panel. CuClad laminates are uniquely cross-piled, with successive layers oriented 90° to each other. This construction provides true electrical and mechanical isotropy in the XY plane—a distinguishing feature not available in other woven or non-woven PTFE-glass laminates. Thanks to these advanced properties, CuClad is an ideal substrate for demanding RF/microwave applications including filters, couplers, low-noise amplifiers, and phased array antennas. Rogers CuClad 233 laminate is engineered with a balanced, medium fiberglass-to-PTFE ratio, resulting in a stable dielectric constant of Er=2.33. This formulation strategically bridges performance gaps by offering a favorable combination of a lower dielectric constant and an improved dissipation factor, all without compromising the mechanical robustness of the material. CuClad 233 laminate is therefore a versatile and reliable choice for a broad spectrum of RF and microwave applications that require consistent electrical performance alongside structural integrity. Features & Benefits Cross Plied Woven Fiberglass, alternating plies are oriented 90o to each other High PTFE to Glass Ratio Better dielectric constant uniformity than comparable non-woven fiberglass reinforced laminates Electrical and Mechanical Isotropy in theX-Y Plane Extremely Low Loss Well Suited for Er Sensitive Circuits Data Sheet Typical Properties: CuClad Property Test Method Condition CuClad 217 CuClad 233 Cuclad 250 Dielectric Constant @10 GHz IPC TM-650 2.5.5.5 C23/50 2.17, 2.20 2.33 2.40 to 2.55 Dielectric Constant @1MHz IPC TM-650 2.5.5.3 C23/50 2.17, 2.20 2.33 2.40 to 2.60 Dissipation Factor @10 GHz IPC TM-650 2.5.5.5 C23/50 0.0009 0.0013 0.0017 Thermal Coefficient of Er (ppm/°C) IPC TM-650 2.5.5.5 Adapted -10°C to +140°C -160 -161 -153 Peel Strength (lbs.per inch) IPC TM-650 2.4.8 After Thermal Stress 14 14 14 Volume Resistivity (MΩ-cm) IPC TM-650 2.5.17.1 C96/35/90 2.3 x 10 8 8.0 x 10 8 8.0 x 10 9 Surface Resistivity (MΩ) IPC TM-650 2.5.17.1 C96/35/90 3.4 x 10 6 2.4 x 10 6 1.5 x 10 8 Arc Resistance (seconds) ASTM D-495 D48/50 >180 >180 >180 Tensile Modulus (kpsi) ASTM D-638 A, 23°C 275, 219 510, 414 725, 572 Tensile Strength (kpsi) ASTM D-882 A, 23°C 8.8, 6.6 10.3, 9.8 26.0, 20.5 Compressive Modulus (kpsi) ASTM D-695 A, 23°C 237 276 342 Flexural Modulus (kpsi) ASTM D-790 A, 23°C 357 371 456 Dielectric Breakdown (kv) ASTM D-149 D48/50 > 45 > 45 > 45 Specific Gravity (g/cm3) ASTM D-792 Method A A, 23°C 2.23 2.26 2.31 Water Absorption (%) MIL-S-13949H 3.7.7 IPC TM-650 2.6.2.2 E1/105 + D24/23 0.02 0.02 0.03 Coefficient of Thermal Expansion (ppm/°C) X Axis Y Axis Z Axis IPC TM-650 2.4.24 Mettler 3000 Thermomechanical Analyzer 0°C to 100°C 29 28 246 23 24 194 18 19 177 Thermal Conductivity ASTM E-1225 100°C 0.26 0.26 0.25 Outgassing Total Mass Loss (%) Collected Volatile Condensable Material (%) Water Vapor Regain (%) Visible Condensate (±) NASA SP-R-0022A Maximum 1.00% Maximum 0.10% 125°C, ≤ 10-6 torr 0.01 0.01 0.00 NO 0.01 0.01 0.00 NO 0.01 0.00 0.00 NO Flammability UL 94 Vertical Burn IPC TM-650 2.3.10 C48/23/50, E24/125 Meets requirements of UL94-V0 Meets requirements of UL94-V0 Meets requirements of UL94-V0 Our PCB Capability ( CuClad ) Rogers CuClad233 PCBs are available with standard electrodeposited copper cladding of ½ oz, 1 oz, or 2 oz on both sides, with options for other copper weights and rolled copper foil upon request. These laminates can also be supplied bonded to a heavy‑metal ground plane using aluminum, brass, or copper plates, which serve as an integral heat sink while providing enhanced mechanical support to the substrate. When placing an order for CuClad products, please specify key parameters such as the dielectric constant, thickness, copper cladding type and weight, panel size, and any other special requirements. Standard panel sizes include 36” x 36” in a cross‑plied configuration and 36” x 48” in a parallel‑plied configuration. For custom sizes or technical assistance, our engineering team is ready to support your project needs. A PCB and Typical Applications Rogers CuClad 233 PCB serves as a design enabler for next-generation high-frequency systems. Engineered to deliver stable electrical performance and excellent mechanical rigidity, it is the material of choice for demanding military and aerospace applications like radar and ECM/ESM, as well as for telecommunications infrastructure and precision RF components including LNAs and filters. By offering consistent signal integrity and thermal stability, CuClad 233 PCB empowers engineers to push the boundaries of innovation in phased arrays, satellite communications, and advanced sensing technologies.