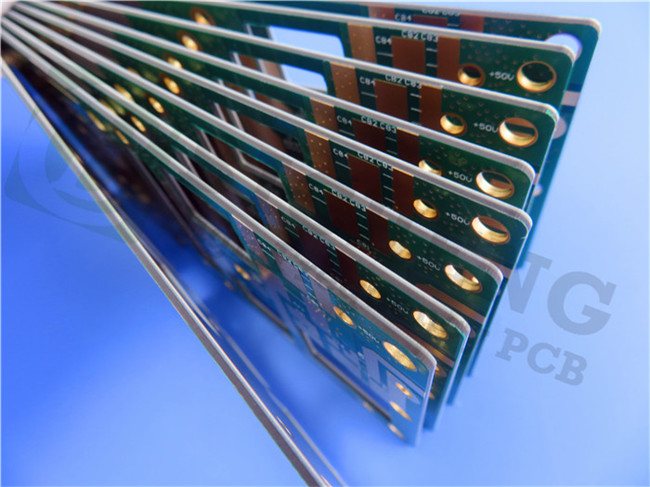

TMM10 High Frequency PCB Material Introduction Welcome back to our channel. My name is Jane, and I work for Bicheng PCB as the regional sales manager. Today, I am going to discuss about a type of thermoset microwave material --TMM10 PCB. Rogers TMM 10 high frequency circuit laminate is a ceramic thermoset polymer composite designed for high PTH hole reliability on strip-line and micro-strip applications. Rogers TMM 10 circuit board offers the benefits of both PTFE and ceramic based substrates, but is not limited by the same mechanical properties and production techniques. Let's start by reviewing the TMM10 data sheet. TMM10 Typical Properties Rogers TMM10 is high dielectric constant PCB material, process Dk valuing 9.2. High DK material is helpful for these devices which need small volume in size such as filters and couplers etc. Dissipation factor is as low as 0.0022 at 10 GHz. Thermal coefficient of dielectric constant, also known as the temperature coefficient of dielectric constant (TCDk) comes next. TCDk less than |50| ppm/°C is considered desirable for all materials as DK changes with temperature. TMM10 has a TCDk of 38 absolute value here, indicating that it has a good TCDk value and is ideal for application in areas such as automotive electronics or 5G base station etc. where boards have to be mounted in highly variable temperature environments. Volume resistivity and surface resistivity are good. The decomposition temperature(Td) can bear 425℃(Thermogravimetric Analysis - TGA). This is a safe temperature during PCB assembly. Coefficient of thermal expansion in X Y Z is similar to that of copper, this ensure its mechanical properties resist creep and cold flow. Rogers TMM10 laminate is a sort of thermal management board with a thermal conductivity of 0.76 W/m/K. Then next, the copper peel strength after thermal stress is 5.0 lbs/inch (0.9 N/mm). The flexural strength in machine direction and cross direction is 13.62 Kpsi, and flexural modulus is 1.79 Mpsi. Moisture absorption for 1.27mm material is 0.09% and 0.2% for 3.18mm thickness. The specific gravity is 2.77 and the specific heat capacity is 0.74 J/g/K. TMM10 is lead free process compatible. TMM10 Typical Value Property TMM10 Direction Units Condition Test Method Dielectric Constant, ?εProcess 9.20±0.23 Z 10 GHz IPC-TM-650 2.5.5.5 Dielectric Constant, ??εDesign 9.8 - - 8GHz to 40 GHz Differential Phase Length Method Dissipation Factor (process) 0.0022 Z - 10 GHz IPC-TM-650 2.5.5.5 Thermal Coefficient of dielectric constant -38 - ppm/℃ -55℃-125℃ IPC-TM-650 2.5.5.5 Volume Resistivity 2 x 108 - Mohm.cm - ASTM D257 Surface Resistivity 4 x 107 - Mohm - ASTM D257 Decomposition Temperature(Td) 425 425 ℃TGA - ASTM D3850 Coefficient of Thermal Expansion - X Y Z 21,21,20 X,Y,Z ppm/℃ 0 to 140 ℃ ASTM E 831 IPC-TM-650, 2.4.41 Thermal Conductivity 0.76 Z W/m/K 80 ℃ ASTM C518 Copper Peel Strength after Thermal Stress 5.0 (0.9) X,Y lbs/inch (N/mm) after solder float 1 oz. EDC IPC-TM-650 Method 2.4.8 Flexural Strength (MD/CMD) 13.62 X,Y kpsi A ASTM D790 Flexural Modulus (MD/CMD) 1.79 X,Y Mpsi A ASTM D790 Moisture Absorption 1.27mm (0.050") 0.09 - % D/24/23 ASTM D570 3.18mm (0.125") 0.2 Specific Gravity 2.77 - - A ASTM D792 Specific Heat Capacity 0.74 - J/g/K A Calculated Lead-Free Process Compatible YES - - - - PCB Capability (TMM10) The table on the screen shows our PCB capability on TMM10 material. We have single layer board, double layer board, multi-layer board and hybrid designs available. Finished copper on tracks can be 1oz and 2oz. Rogers TMM 10 high frequency PCBs are available in a variety of thicknesses, including the commonly used 20 mils, 30 mils, 50 mils, and 60 mils. There are also high thicknesses such as 200 mils, 300 mils, and 500 mils, among others. Our maximum PCB size on high frequency materials is 400mm by 500mm, which can be a single board in the sheet or multiple designs in this panel. Solder masks in green, black, blue,red and yellow etc are available in house. Immersion gold, HASL, immersion silver, and immersion tin, as well as OSP, ENEPIG, and pure gold are available to protect the SMD pads. PCB material: Ceramic, Hydrocarbon, Thermoset Polymer Composites Designation: TMM10 Dielectric constant: 9.20 ±0.23 Layer count: Double layer, Multi-layer, Hybrid PCB Copper weight: 1oz (35µm), 2oz (70µm) PCB thickness: 15mil (0.381mm), 20mil (0.508mm), 25mil (0.635mm), 30mil(0.762mm), 50mil (1.27mm), 60mil (1.524mm), 75mil(1.905mm), 100mil (2.54mm), 125mil (3.175mm), 150mil (3.81mm), 200mil (5.08mm), 250mil (6.35mm), 275mil (6.985mm), 300mil (7.62mm), 500mil (12.70mm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Red, Yellow etc. Surface finish: Immersion gold, HASL, Immersion silver, Immersion tin, Bare copper, OSP, ENEPIG, Pure gold etc.. A Piece of TMM10 PCB On the screen now is a type of 150 mils TMM10 PCB with immersion gold. It is a simple board with exquisite workmanship. We can find their applications in power amplifiers and combiners, filters and couplers, satellite communication systems, global positioning systems antennas and patch antennas etc. Conclusion Rogers TMM 10 circuit materials are resistant to process chemicals, and damage is reduced during the whole circuit fabrication. It does not require a sodium napthanate treatment prior to electroless plating and it allows for reliable wire-bonding due to its thermoset resin. OK. Thanks for your reading. I’ll see you next time.