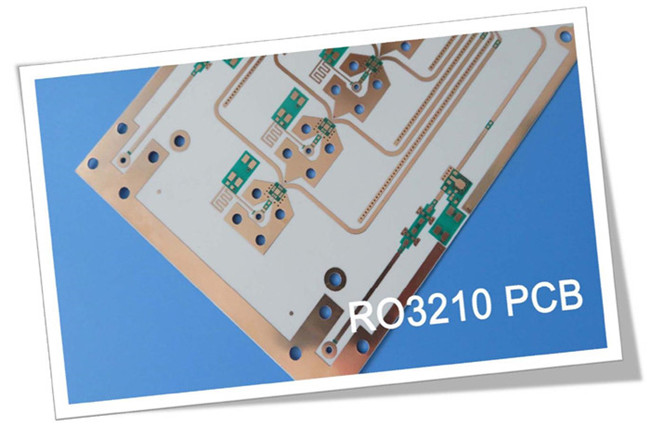

RO3210 High Frequency PCB Material Introduction Hello everyone,and welcome back to our channel. My name is Ivy, and I work as the regional sales manager at Bicheng PCB. Today, our topic is about an extension material of Rogers RO3000 series that has one distinguishing characteristic: enhanced mechanical stability. That is RO3210 high frequency PCB, which is the feature product today. Rogers RO3210 high frequency PCB materials are ceramic-filled laminates reinforced with woven fiberglass. They are engineered to offer exceptional electrical performance and improved mechanical stability at competitive prices. To begin with, let’s look at the data sheet of RO3210 PCB materials. RO3210 Typical Properties The data sheet shows the basic properties of this high frequency circuit laminates. Item 1 is dielectric constant. RO3210 is a high DK material with a vale of 10.2 and a dissipation factor of .0027 at 10 GHz and 23 ℃. Its dielectric constant and dissipation factor are tightly controlled to a tolerance shown here. The next one is thermal coefficient of dielectric constant (TCDk). TCDk is a property that all materials have and it describes how much the Dk of the material will change with a change in temperature. Some materials are better another is worse. Basically, TCDk values less than |50| ppm/℃ as considered good and with being 0 ppm/℃would be ideal, that is to say DK does not alter with a change in temperature. Back to the TCDk of RO3210, -459 ppm/℃,actually this is a poor TCDk. RO3210 will not be taken into consideration when a circuit board must be installed in highly temperature-varying environments, for example in automotive electronics or 5G base stations. Volume resistivity and surface resistivity are actually good. Those are excellent in the range of most of printed circuit board materials. Water absorption of less than 0.1% is a really big deal, because no matter how good the RF properties of the material are, if the moisture absorption is not good, then as the PCB behaves and performs in the different environments, different humidity can absorb or release this moisture and that different moisture causes a difference in dielectric constant and dissipation factor. So this moisture absorption is set less than 0.1%, which is regarded extremely good. The specific heat value is 0.79 J/g/K. Water has a specific heat of 4.186 J/g/K, copper has 0.385 J/g/K, and lead 0.128 J/g/K. The thermal conductivity is 0.81 W/mK, which is acceptable. Coefficient of thermal expansion (-55 to 288 °C) exhibits low in-plane expansion coefficient, 13 ppm/°C in X and Y direction, similar to copper, making it suitable for use with epoxy multi-layer board hybrid designs and allowing for more reliable surface mounted assemblies. The decomposition temperature exceeds 500 °C, and the density is 3 gm/cm3. It’s an off-white colour. It complies with UL-94V0 flammability and is lead free and environmentally friendly. Property Typical Value RO3210 Direction Unit Condition Test Method Dielectric Constant, er Process 10.2± 0.50 Z - 10 GHz 23°C IPC-TM-650 2.5.5.5 Dielectric Constant, er Design 10.8 Z - 8 ?GHz - 40 GHz Differential Phase Length Method Dissipation Factor, tan d 0.0027 Z - 10 GHz 23°C IPC-TM-650 2.5.5.5 Thermal Coefficient of er -459 Z ppm/°C 10 GHz 0-100°C IPC-TM-650 2.5.5.5 Dimensional Stability 0.8 X,Y mm/m COND A ASTM D257 Volume Resistivity 103 MW•cm COND A IPC 2.5.17.1 Surface Resistivity 103 MW COND A IPC 2.5.17.1 Tensile Modulus 579 MD CMD kpsi 23°C ASTM D638 Water Absorption <0.1 - % D24/23 IPC-TM-650 2.6.2.1 Specific Heat 0.79 J/g/K Calculated Thermal Conductivity 0.81 - W/m/K 80°C ASTM C518 Coefficient of Thermal Expansion (-55 to 288 °C) 13 X,Y Z ppm/°C 23°C/50% RH IPC-TM-650 2.4.41 Td 500 °C TGA ASTM D3850 Density 3.0 gm/cm3 Color Off White Flammability V-0 UL 94 Lead Free Process Compatible YES PCB Capability (RO3210) For RO3210 PCBs, we can provide you with single layer board, double layer board, multi-layer board and hybrid types. Rogers RO3210 PCBs are typically available in two thicknesses for our application: 25 mils and 50 mils. Finished copper on track lines can be 1oz, 2oz or 3oz. Our maximum PCB size on high frequency materials is 400mm by 500mm, which can be a single board in the sheet or multiple designs in this panel. Solder masks in green, black, blue, and yellow etc. are available in the house. Surface pads are available in immersion gold, HASL, immersion silver, immersion tin, and OSP etc. PCB Material: Woven-Glass Reinforced Ceramic-filled Laminates Designation: RO3210 Dielectric constant: 10.2 ±0.5 (process) 10.8 (design) Layer count: 1-layer, 2-layer, Multi-layer, Hybrid PCB PCB thickness: 25mil (0.635mm), 50mil (1.27mm) Copper weight: 1oz (35µm), 2oz (70µm), 3oz (105µm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Yellow, Red etc. Surface finish: Immersion gold, HASL, Immersion silver, Immersion tin, Bare copper, OSP etc.. A Piece of RO3210 PCB The screen shows a 25mil double sided PCB on RO3210 material with immersion gold, no solder mask, and no silkscreen. Rogers RO3210 PCBs are commonly utilized in automotive collision avoidance systems, automotive global positioning satellite antennas, base station infrastructure, direct broadcast satellite and Wireless telecommunications systems etc. Conclusion Rogers RO3210 high frequency PCB boards combine the surface smoothness of a non-woven PTFE circuit with the rigidity of a woven-glass PTFE board. The manufacturing process of RO3210 high frequency PCB is similar to standard PTFE circuit board processing techniques. OK. This concludes the episode. Thank you for your reading. Should you have any questions, please feel free to contact us. See you next time.

Clamped Stripline

517

34