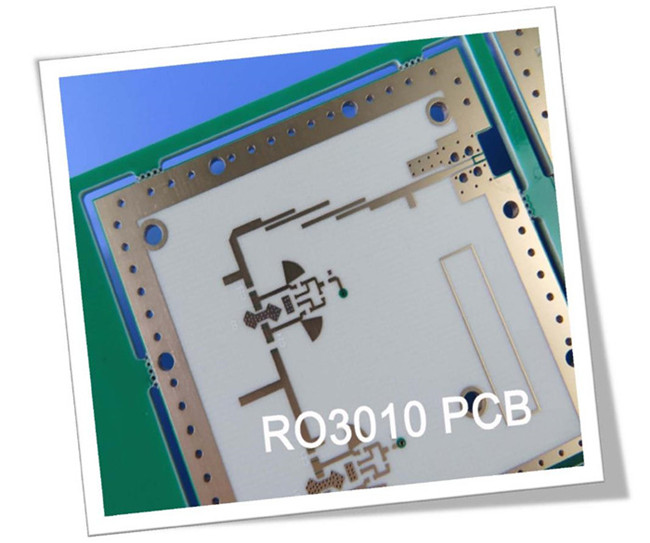

RO3010 High Frequency PCB Material Introduction Hello Everyone. Welcome back to our channel. My name is Jane, the sales manager for Bicheng PCB. Today we’ll spend a few minutes to talk about a ceramic-filled PTFE composite that offers exceptional electrical and mechanical stability. Rogers’ RO3010 high frequency PCBs are ceramic-filled PTFE composites designed for commercial microwave and radio frequency applications. These laminates possess excellent electrical properties and consistent mechanical properties, allowing our designers to create multilayer boards designs that use different dielectric constant materials for individual layers without experiencing any warpage or reliability issues. Let’s start to look at the data sheet. RO3010 Typical Properties The data sheet shows a variety of different properties of the material. The dielectric constant of RO3010 material is typically 10.2 with a tolerance of ±0.15. The dielectric constant of RO3010 material is typically 10.2 with a tolerance of ±0.15. However, the thermal coefficient of dielectric constant in the Z direction is ?395 ppm/°C at 10 GHz ranging -50℃to 150℃. This value actually performs high which is not suitable for temperature sensitive working sites. The dimensional stability of RO3010 is worthy of attention, in X and Y direction, there’s only 0.35 and 0.31 mm/m. This means the material is less likely to warp or deform during manufacturing, ensuring the final product meet specifications. The volume resistivity and surface resistivity are also impressive, at 105 MΩ.cm and 105 MΩ respectively. This resistivity helps control the flow of electricity within the circuit and ensures efficient transmission of signals. Rogers RO3010 exhibits a tensile modulus in excess of 1900 MPa in the X and Y directions. The moisture absorption is 0.05%, indicating its resistance to water intrusion. In addition, the specific heat capacity was calculated at 0.8 J/g/K, demonstrating its ability to absorb thermal energy. Moreover, the thermal conductivity measured by the ASTM D 5470 method at a temperature of 50°C is 0.95 W/m/K, indicating a good thermal conductivity. Carried out at 23°C and 50% relative humidity with test method of IPC-TM-650 2.4.4.1., the material's coefficient of thermal expansion (CTE) in a temperature range of -55 to 288°C yields value of 13, 11, and 16 ppm/°C respectively in X, Y and Z direction. This is a pretty good result because the CTE is similar to that of copper, making the PCBs give excellent performance in the dimensional stability and plated-through-holes reliability. Rogers RO3010 PCB is resistant to decomposition temperatures up to 500°C. Additionally, it was tested and confirmed to have a density of 2.8 gm/cm3 at 23°C. RO3010 has a copper peel strength of 9.4 lbs/in after solder float measured on IPC-TM 2.4.8 using 1oz ED copper. Rogers RO3010 PCB is classified as V-0 flammability according to UL 94 standard and has the advantage of being compatible with lead-free processes as well. RO3010 Typical Value Property RO3010 Direction Units Condition Test Method Dielectric Constant,εProcess 10.2±0.05 Z 10 GHz/23℃ IPC-TM-650 2.5.5.5 Clamped Stripline Dielectric Constant,εDesign 11.2 Z 8GHz to 40 GHz Differential Phase Length Method Dissipation Factor,tanδ 0.0022 Z 10 GHz/23℃ IPC-TM-650 2.5.5.5 Thermal Coefficient of ε -395 Z ppm/℃ 10 GHz -50℃to 150℃ IPC-TM-650 2.5.5.5 Dimensional Stability 0.35 X mm/m COND A IPC-TM-650 2.2.4 Volume Resistivity 105 MΩ.cm COND A IPC 2.5.17.1 Surface Resistivity 105 MΩ COND A IPC 2.5.17.1 Tensile Modulus 1902 X MPa 23℃ ASTM D 638 Moisture Absorption 0.05 % D48/50 IPC-TM-650 2.6.2.1 Specific Heat 0.8 j/g/k Calculated Thermal Conductivity 0.95 W/M/K 50℃ ASTM D 5470 Coefficient of Thermal Expansion 13 X ppm/℃ 23℃/50% RH IPC-TM-650 2.4.4.1 Td 500 ℃ TGA ASTM D 3850 Density 2.8 gm/cm3 23℃ ASTM D 792 Copper Peel Stength 9.4 Ib/in. 1oz,EDC After Solder Float IPC-TM 2.4.8 Flammability V-0 UL 94 Lead-free Process Compatible Yes PCB Capability (RO3010) For Rogers RO3010 PCB, it is available with double layer, multilayer and hybrid designs. It is available in a range of copper weight options such as 1oz (35μm) and 2oz (70μm), and the PCB thickness can be customized with options including 5mil (0.127mm), 10mil (0.254mm), 25mil (0.635mm) and 50mil (1.27mm). The maximum PCB size of RO3010 is within 400mm X 500mm. It can be a single board size or multiple designs in the panel. We also offers solder mask in various colors including green, black, blue, yellow, red, white and more. We also offers solder mask in various colors including green, black, blue, yellow, red, white and more. PCB Material: Ceramic-filled PTFE composite Designation: RO3010 Dielectric constant: 10. 2 ±0.3 (process Dk) 11.2 (design Dk) Layer count: Double layer, Multi-layer, Hybrid designs Copper weight: 1oz (35µm), 2oz (70µm) PCB thickness: 5mil (0.127mm), 10mil (0.254mm), 25mil (0.635mm), 50mil (1.27mm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Yellow, Red, White etc. Surface finish: Immersoin gold, HASL, Immersion silver, Immersion tin, Bare copper, OSP, ENEPIG etc.. A Piece of RO3010 PCB Displayed on the screen is a 60mil RO3010 PCB with immersion silver coating for power amplifiers and antennas. They can be also found in the field of automotive radar applications, GPS antennas, patch antennas for wireless communications, and direct broadcast satellite etc. Conclusion The manufacturing process of RO3010 high frequency PCB is similar to standard PTFE PCB. Developers, strippers, and copper etchants used to process epoxy glass materials will also work with RO3010. So it’s suitable for volume manufacturing process to win advantageous market. Should you have any questions, please feel free to contact us. Thank you for reading. We’ll see you next time.

0.31

Y

1934

Y

(-55 to 288℃)

11

16

Y

Z