Home

-

Others

-

S1000-2M High Performance PCB High Tg and Low Water Absorption Printed Circuit Board by Shengyi

Home

-

Others

-

S1000-2M High Performance PCB High Tg and Low Water Absorption Printed Circuit Board by Shengyi

S1000-2M High Performance PCB High Tg and Low Water Absorption Printed Circuit Board by Shengyi

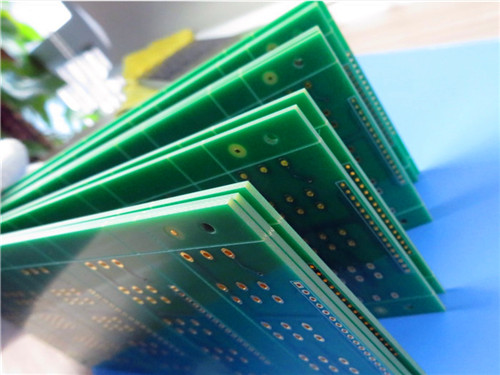

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

Brief Introduction

S1000-2M PCB is an advanced high-Tg circuit board material engineered by Shengyi to deliver exceptional performance for demanding electronic applications. This high-performance laminate features controlled thermal expansion properties and is specifically designed to support complex, high-layer-count PCB designs. The material accommodates diverse manufacturing requirements with thickness options ranging from 0.05mm to 3.2mm and copper weights from 0.5oz to 3oz, providing design flexibility for various multilayer board applications.

Features

Lead-free compatible FR-4 laminate

Tg170℃ (DSC), UV Blocking/AOI compatible

High heat resistance

Lower Z-axis CTE

Excellent through-hole reliability

Excellent Anti-CAF performance

Low water absorption

Excellent mechanical processability

Applications

Computer

Communication

Automotive electronics

Suitable for high layer count PCB

.jpg)

Our PCB Capability (S1000-2M)

| Our PCB Capability (S1000-2M) | |

| PCB Material: | High Tg, High Performance and Low CTE Epoxy Resin |

| Designation: | S1000-2M |

| Dielectric constant: | 4.6 at 10GHz |

| Layer count: | Double Layer, Multilayer, Hybrid PCB |

| Copper weight: | 0.5oz (17 µm), 1oz (35µm), 2oz (70µm), 3oz (105µm) |

| PCB thickness: | 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.6mm, 1.8mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Matt Black, Blue, Matt Blue, Yellow, Red etc. |

| Surface finish: | Bare copper, HASL, ENIG, OSP, Immersion tin, Immersion Silver, ENEPIG, Pure gold etc.. |

| Technology: | HDI, Via in pad, Impedance Control, Blind via/Buried via, Edge Plating, BGA, Countsunk Holes etc. |

General Properties of S1000-2M

| Test Items | Test Method | Test Condition | Unit | Typical Value |

| Tg | IPC-TM-650 2.4.24.4 | DMA | ℃ | 185 |

| IPC-TM-650 2.4.25D | DSC | ℃ | 180 | |

| Td | IPC-TM-650 2.4.24.6 | TGA (5% W.L) | ℃ | 355 |

| T260 | IPC-TM-650 2.4.24.1 | TMA | min | >60 |

| T288 | IPC-TM-650 2.4.24.1 | TMA | min | 30 |

| T300 | IPC-TM-650 2.4.24.1 | TMA | min | 15 |

| Thermal Stress | IPC-TM-650 2.4.13.1 | 288℃, solder dip | s | >100 |

| CTE (Z-axis) | IPC-TM-650 2.4.24 | Before Tg | ppm/℃ | 41 |

| IPC-TM-650 2.4.24 | After Tg | ppm/℃ | 208 | |

| IPC-TM-650 2.4.24 | 50-260℃ | % | 2.4 | |

| Permittivity (1GHz) | IPC-TM-650 2.5.5.9 | C-24/23/50 | - | 4.6 |

| Loss Tangent (1GHz) | IPC-TM-650 2.5.5.9 | C-24/23/50 | - | 0.018 |

| Volume Resistivity | IPC-TM-650 2.5.17.1 | C-96/35/90 | MΩ-cm | 8.7×108 |

| Surface Resistivity | IPC-TM-650 2.5.17.1 | C-96/35/90 | MΩ | 2.2×107 |

| Arc Resistance | IPC-TM-650 2.5.1 | D-48/50+D-0.5/23 | s | 133 |

| Dielectric Breakdown | IPC-TM-650 2.5.6 | D-48/50+D-0.5/23 | kV | >45 |

| Peel Strength (1oz) | IPC-TM-650 2.4.8 | 288℃/10s | N/mm [lb/in] | 1.3 [7.43] |

| Flexural Strength (LW/CW) | IPC-TM-650 2.4.4 | A | Mpa | 567/442 |

| Water Absorption | IPC-TM-650 2.6.2.1 | D-24/23 | % | 0.08 |

| Flammability | UL94 | C-48/23/50 | Rating | V-0 |

| CTI | IEC60112 | A | Rating | PLC 3 |