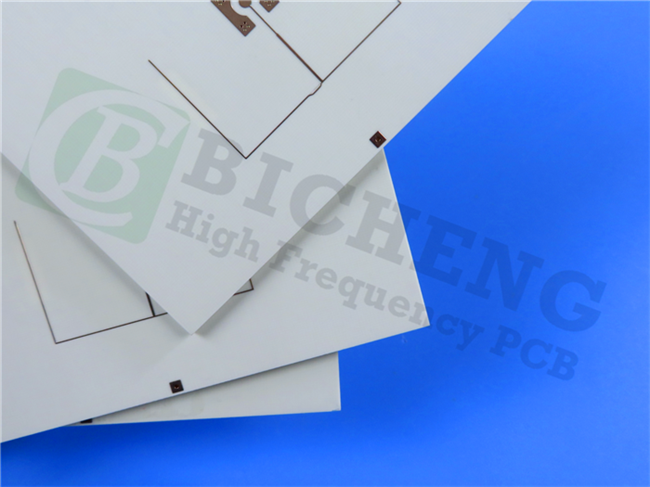

Kappa 438 High Frequency PCB Material Introduction Hello and welcome back to our channel. My name is Ivy, the sales manager at Bicheng PCB, and it's wonderful to see you here again. In today's discussion, we will explore Rogers Kappa 438 PCBs, a superior choice for wireless circuit designers as an alternative to FR-4 materials. These PCBs offer enhanced performance, consistency, and reliability, all while being cost-effective and user-friendly. Rogers Kappa 438 laminates are designed with a hydrocarbon ceramic system reinforced with glass. This low-loss material can be manufactured using standard epoxy/glass (FR-4) processes, simplifying circuit fabrication tasks. Kappa 438 laminates are rated UL 94 V-0 for flame retardancy and are compatible with lead-free solder processes. Now let’s start from the data sheet. Kappa 438 Typical Properties The dielectric constant of the material is 4.38 at 2.5 GHz, with a dissipation factor of 0.005 at 10 GHz and 23°C. The thermal coefficient of dielectric constant is -21 ppm/°C at 10 GHz over a temperature range of -50°C to 150°C. Rogers Kappa 438 PCB has a volume resistivity of 2.9 x 10^9 Mcm and a surface resistivity of 6.2 x 10^7 M. Its electrical strength is 675 V/mil. In terms of mechanical properties, the material has a tensile strength of 16 kpsi and 12 kpsi in the MD and CMD directions, respectively, as well as a flexural strength of 25 kpsi and 19 kpsi in the MD and CMD directions, respectively. In terms of mechanical properties, the material has a tensile strength of 16 kpsi and 12 kpsi in the MD and CMD directions, respectively, as well as a flexural strength of 25 kpsi and 19 kpsi in the MD and CMD directions, respectively. Coefficient of thermal expansion indicates how much a material will expand or contract with changes in temperature. Kappa 438 has a CTE of 13 ppm/°C in X axis over a temperature range of -55 to 288°C, measured using the IPC-TM-650 2.4.41 test method. It also has a CTE of 16 ppm/°C in Y direction and 42 ppm/°C in Z direction. Rogers Kappa 438 PCB has a thermal conductivity of 0.64 W/(m.K) at 80°C, indicating it is capable of efficiently conducting heat away from the electronic components, ensuring that the device operates efficiently and doesn't overheat. Time to delamination is over 60 minutes at 288°C, indicating that Kappa 438 can withstand high temperatures for a long period without any delamination. Its Tg is greater than 280°C, indicating that Kappa 438 can withstand high temperatures without losing its mechanical properties or becoming brittle, and its Td is 414°C. Rogers Kappa 438 has a moisture absorption rate of 0.07%, we have confidence the material is resistant to water and will not be affected by the presence of moisture in the device's environment. A high Young's modulus value of 2264 kpsi and a high flex modulus value of 2337 kpsi indicate that Kappa 438 is strong and can withstand mechanical stress without deforming or breaking. A low bow value of 0.03% and a low twist value of 0.08% also indicate the material has good dimensional stability and will not deform or warp during the manufacturing process or in use. The copper peel strength value of 5.8 lbs/in for 1 oz (35 μm) foil indicates that Kappa 438 has good adhesion properties and can withstand thermal stress without delaminating. It has a flammability rating of V-0 according to UL 94, indicating that the material is self-extinguishing and will not propagate a flame in case of a fire A specific gravity value of 1.99 g/cm3 indicates Kappa 438 is relatively dense and can provide good mechanical support to electronic components. Finally, Kappa 438 is lead-free process compatible. Our PCB Capability (Kappa 438) Rogers Kappa 438 PCB is available in different layer counts, including double layer, Multi-layer, and Hybrid PCBs. Customers can choose from copper weights of 1oz (35μm) or 2oz (70μm). In terms of thickness, Kappa 438 PCB is available in 20mil, 30mil, 40mil, and 60mil variants. Additionally, the maximum size of Kappa PCB that can be produced with Kappa 438 is 400mm X 500mm, which is suitable for most electronic devices. Customers have the flexibility to select from a variety of solder mask colors, including Green, Black, Blue, Yellow, Red etc. Moreover, Various surface finish options are available, including immersion gold, HASL, immersion silver, immersion tin, pure gold, OSP, ENEPIG, bare copper, and several others. PCB material: Glass Reinforced Hydrocarbon Ceramic Substrates Designation: Kappa 438 Dielectric constant: 4.38 Layer count: Double layer, Multi-layer, Hybrid PCB Copper weight: 1oz (35µm), 2oz (70 µm) PCB thickness: 20mil (0.508mm), 30mil (0.762mm), 40mil (1.016mm), 60mil (1.524mm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Yellow, Red etc. Surface finish: Immersion gold, HASL, Immersion silver, Immersion tin, Pure gold, OSP, ENEPIG, Bare copper, etc.. A Piece of Kappa 438 PCB Now displayed on the screen is a 60mil Kappa 438 high frequency PCB with immersion gold for carrier grade WiFi. Rogers Kappa 438 PCB is a versatile option that can be used in a range of applications. It is particularly well-suited for Licensed Assisted Access (LAA), ideal for Small Cell and Distributed Antenna Systems (DAS), high-performance and reliable connectivity for Vehicle-to-Vehicle (V2V) and Vehicle-to-Infrastructure (V2I) communications Additionally, for Internet of Things (IoT) applications, it is ideal for use in Smart Home and Wireless Meters, providing efficient and secure wireless communication. Conclusion With Kappa 438 laminates, wireless circuit designers can achieve a true breakthrough due to their exceptional performance that surpasses the limitations of FR-4 materials. These laminates offer an ideal balance of price, performance, and reliability and can be fabricated using standard epoxy/glass (FR-4) processes. They are also compatible with conventional bondplies and lead-free solder processes. OK. That concludes today’s episode. Thanks for reading. See you next time.