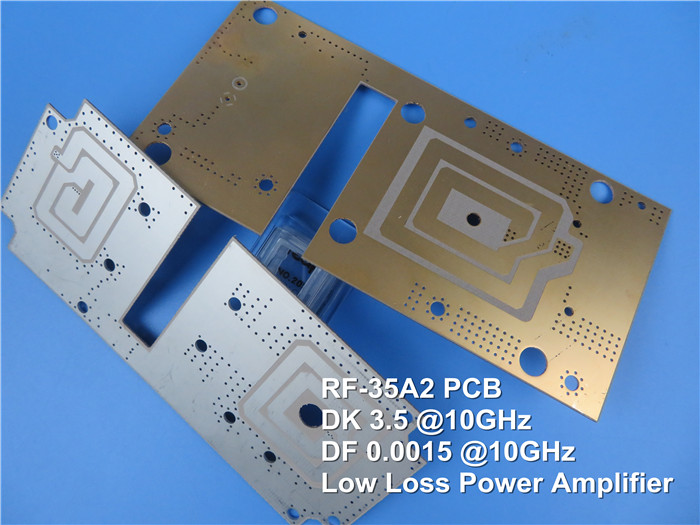

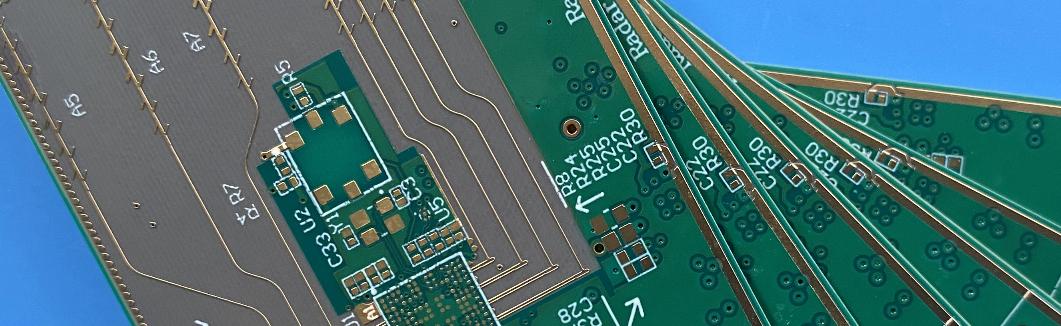

Taconic RF-35A2 High Frequency PCB Material Introduction Taconic’s RF-35A2 substrate is designed to have ultra-low fiberglass content to achieve "best in class" insertion loss properties and the uniform dielectric constant 3.5 +/-0.05 throughout the laminate. It is a type of ultra low loss power amplifier material. The uniform dispersion of ceramics throughout the laminate yields an extremely low X and Y thermal expansion coefficient. Low modulus and low X-Y CTE values make RF-35A2 an attractive PCB material for chip carrier in surface mounting technology. Taconic RF-35A2 laminate is manufactured with a proprietary multi-step process with excellent dielectric performance and excellent copper peel adhesion.The low 0.0015 dissipation factor at 10 GHz allows for maximum power transfer resulting in low heat generation. Benefits: Low loss properties DK tolerance of +/- 0.05 Homogeneous DK Excellent peel strength Low moisture absorption Applications: Power amplifiers Filters / couplers High speed digital Passive components Wireless antennas Our PCB Capabilities (RF-35A2) PCB Material: PTFE Ceramic Fiberglass Designation: RF-35A2 Dielectric constant: 3.15 Dissipation Factor 0.0015 Layer count: Double Layer, Multilayer, Hybrid PCB Copper weight: 0.5oz (17 µm), 1oz (35µm) Laminate thickness: 10mil (0.254mm), 20mil (0.508mm), ?30mil (0.762mm), ?60mil (1.524mm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Yellow, Red etc. Surface finish: Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP etc.. Typical Value of Taconic RF-35A2 PCB Property Test Method Unit Value Unit Dk @ 10 GHz IPC-650 2.5.5.5.1 (Modified) 3.5 Df @ 10 GHz IPC-650 2.5.5.5.1 (Modified) 0.0015 Moisture Absorption IPC-650 2.6.2.1 % 0.03 % Dielectric Breakdown IPC-650 2.5.6/ASTM D 149 kV 59 kV Dielectric Strength ASTM D 149 V/mil 1000 V/mm Volume Resistivity IPC-650 2.5.17.1 Sec. 5.2.1 (Humidity Cond.) Mohm/cm 10^9 Mohm/cm Surface Resistivity IPC-650 2.5.17.1 Sec. 5.2.1 (Humidity Cond.) Mohm 10^8 Mohm Arc Resistance IPC-650 2.5.1 Seconds 242 Seconds Flexural Strength (MD) IPC-650 2.4.4 kpsi 24 N/mm2 Flexural Strength (CD) IPC-650 2.4.4 kpsi 15 N/mm2 Tensile Strength (MD) ASTM D 3039 psi 16,800 N/mm2 Tensile Strength (CD) ASTM D 3039 psi 11,000 N/mm2 Young’s Modulus (MD) ASTM D 3039 psi 106 N/mm2 Young’s Modulus (CD) ASTM D 3039 psi 106 N/mm2 Poisson’s Ratio (MD) ASTM D 3039 0.14 Poisson’s Ratio (CD) ASTM D 3039 0.1 Strain at Break (MD) ASTM D 3039 % 1.6 % Strain at Break (CD) ASTM D 3039 % 1.4 % Compressive Modulus (Z axis) ASTM D 695 (23°C) kpsi 385 N/mm2 Peel Strength (1 oz. VLP) IPC-650 2.4.8 (Thermal Stress) lbs/in 12 N/mm Peel Strength (1 oz. VLP) IPC-650 2.4.8.3 (150°C ) (Elevated Temp.) lbs/in 14 N/mm Peel Strength (1 oz. VLP) IPC-650 2.4.8 Sec. 5.2.3 (Proc. Chemicals) lbs/in 11 N/mm Density (Specific Gravity) gm/cm3 2.28 gm/cm3 Specific Heat ASTM E 1269 (DSC) (100°C) J/g/K 0.99 J/g/K Thermal Conductivity ASTM F 433 W/M*K 0.29 W/M*K Td IPC-650 2.4.24.6 2% Weight Loss °C 528 °C Td IPC-650 2.4.24.6 5% Weight Loss °C 547 °C CTE (x) IPC-650 2.4.41 (>RT - 125°C) ppm/°C 10 ppm/°C CTE (y) IPC-650 2.4.41 (>RT - 125°C) ppm/°C 13 ppm/°C CTE (z) IPC-650 2.4.41 (>RT - 125°C) ppm/°C 108 ppm/°C