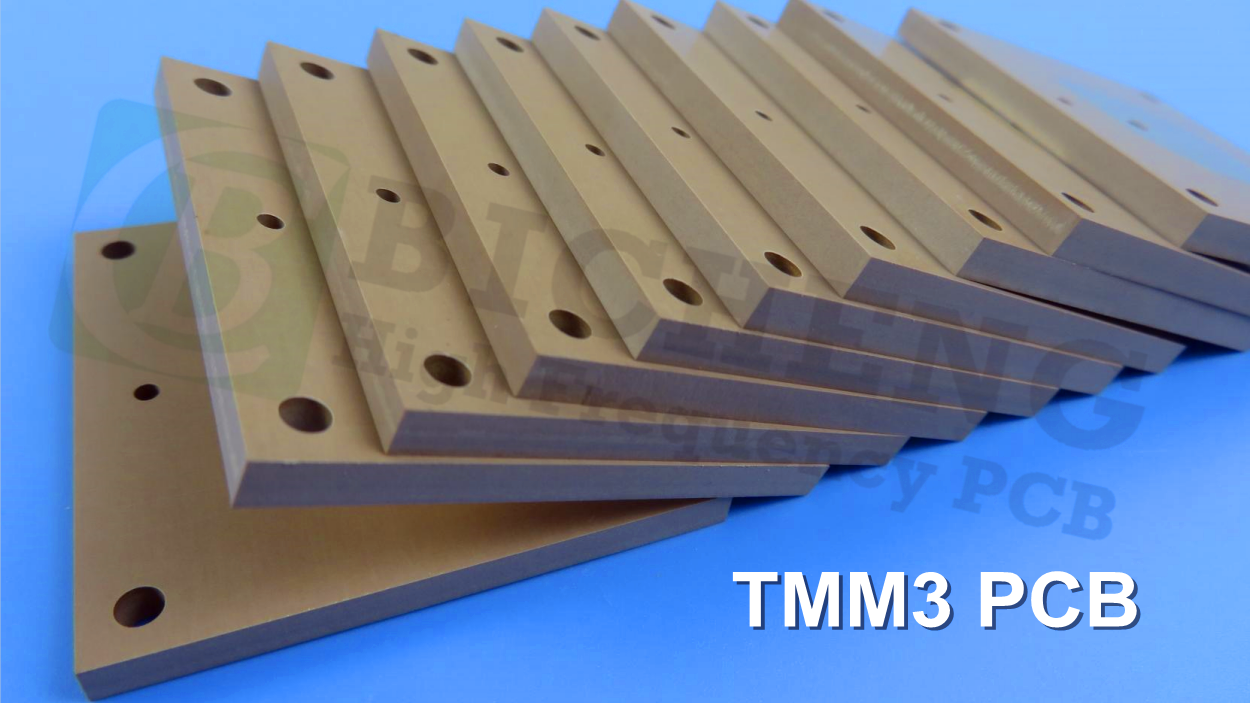

Rogers TMM3 Microwave PCB Material Introduction Hello everyone. Today we’re going to introduce the cutting-edge technology of TMM3 PCBs, which feature a low thermal coefficient of dielectric constant and closely matched coefficients of thermal expansion to copper. Rogers TMM 3 laminates is a thermoset microwave material that utilizes a ceramic thermoset polymer composite. It is specifically engineered for strip-line and micro-strip applications that require high reliability in plated thru-hole connections. TMM 3 laminates offer the advantages of both ceramic and traditional PTFE microwave circuit laminates, but without the need for specialized production techniques typically associated with those materials. By using thermoset resins as the base, TMM laminates ensure reliable wire-bonding without the risks of pad lifting or substrate deformation. This feature enhances the overall reliability and durability of the circuits. Data Sheet TMM3 PCB material offers several valuable properties that make it an excellent choice for various applications. Here are the key characteristics and their typical values: 1. Dielectric Constant: TMM3 has a dielectric constant of 3.27±0.032 (εProcess) and 3.45 (εDesign) at different frequencies. This property determines the material's ability to store electrical energy. 2. Dissipation Factor: The dissipation factor for TMM3 is 0.002, indicating low energy loss as the signal passes through the material. 3. Thermal Coefficient of Dielectric Constant: TMM3 has a positive thermal coefficient of +37 ppm/°K, which means its dielectric constant remains relatively stable over a wide temperature range. 4. Insulation Resistance: TMM3 demonstrates insulation resistance greater than 2000 Gohm, ensuring effective electrical isolation between conductive elements. 5. Volume and Surface Resistivity: TMM3 exhibits volume resistivity of 2 x 10^9 Mohm.cm and surface resistivity greater than 9 x 10^9 Mohm, indicating its excellent electrical insulation properties. 6. Electrical Strength: The dielectric strength of TMM3 is 441 V/mil, indicating its ability to withstand high voltage without breaking down. 7. Thermal Properties: TMM3 has a decomposition temperature (Td) of 425℃, demonstrating its ability to withstand high temperatures without significant degradation. It also exhibits a coefficient of thermal expansion of 15 ppm/K in the X and Y directions, and 23 ppm/K in the Z direction, ensuring dimensional stability over a wide temperature range. The thermal conductivity of TMM3 is 0.7 W/m/K, indicating its ability to dissipate heat efficiently. 8. Mechanical Properties: TMM3 shows good copper peel strength after thermal stress, with a value of 5.7 lb/inch (1.0 N/mm). It also exhibits a flexural strength of 16.53 kpsi and a flexural modulus of 1.72 Mpsi, indicating its mechanical stability and rigidity. 9. Physical Properties: TMM3 has low moisture absorption rates of 0.06% (1.27mm thickness) and 0.12% (3.18mm thickness), ensuring dimensional stability in humid environments. Its specific gravity is 1.78, and specific heat capacity is 0.87 J/g/K. TMM3 is also compatible with lead-free manufacturing processes. TMM3 Typical Value Property TMM3 Direction Units Condition Test Method Dielectric Constant,εProcess 3.27±0.032 Z 10 GHz IPC-TM-650 2.5.5.5 Dielectric Constant,εDesign 3.45 - - 8GHz to 40 GHz Differential Phase Length Method Dissipation Factor (process) 0.002 Z - 10 GHz IPC-TM-650 2.5.5.5 Thermal Coefficient of dielectric constant +37 - ppm/°K -55℃-125℃ IPC-TM-650 2.5.5.5 Insulation Resistance >2000 - Gohm C/96/60/95 ASTM D257 Volume Resistivity 2 x 10^9 - Mohm.cm - ASTM D257 Surface Resistivity 9x 10^9 - Mohm - ASTM D257 Electrical Strength(dielectric strength) 441 Z V/mil - IPC-TM-650 method 2.5.6.2 Thermal Properties Decompositioin Temperature(Td) 425 425 ℃TGA - ASTM D3850 Coefficient of Thermal Expansion - x 15 X ppm/K 0 to 140 ℃ ASTM E 831 IPC-TM-650, 2.4.41 Coefficient of Thermal Expansion - Y 15 Y ppm/K 0 to 140 ℃ ASTM E 831 IPC-TM-650, 2.4.41 Coefficient of Thermal Expansion - Z 23 Z ppm/K 0 to 140 ℃ ASTM E 831 IPC-TM-650, 2.4.41 Thermal Conductivity 0.7 Z W/m/K 80 ℃ ASTM C518 Mechanical Properties Copper Peel Strength after Thermal Stress 5.7 (1.0) X,Y lb/inch (N/mm) after solder float 1 oz. EDC IPC-TM-650 Method 2.4.8 Flexural Strength (MD/CMD) 16.53 X,Y kpsi A ASTM D790 Flexural Modulus (MD/CMD) 1.72 X,Y Mpsi A ASTM D790 Physical Properties Moisture Absorption (2X2) 1.27mm (0.050") 0.06 - % D/24/23 ASTM D570 3.18mm (0.125") 0.12 Specific Gravity 1.78 - - A ASTM D792 Specific Heat Capacity 0.87 - J/g/K A Calculated Lead-Free Process Compatible YES - - - - Our PCB Capability (TMM3) We have the capability to supply double-layer, multilayer, and hybrid PCBs with varying levels of complexity and functionality. Our range of copper weights includes 0.5oz (17 µm), 1oz (35µm), and 2oz (70µm), providing flexibility in designing PCBs to meet specific performance requirements. Our capability covers a wide range of PCB thicknesses, including 15mil (0.381mm), 20mil (0.508mm), 25mil (0.635mm), 30mil (0.762mm), 50mil (1.27mm), 60mil (1.524mm), 75mil (1.905mm), 100mil (2.54mm), 125mil (3.175mm), 150mil (3.81mm), 200mil (5.08mm), 250mil (6.35mm), 275mil (6.985mm), 300mil (7.62mm), and 500mil (12.7mm). This allows for the production of PCBs with varying thicknesses to meet specific design and performance requirements. We can manufacture PCBs with a maximum size of ≤400mm X 500mm. This capability accommodates a wide range of PCB dimensions, providing flexibility in designing PCBs for different applications. We offer various solder mask color options, including green, black, blue, yellow, red, and more. This allows for customization of the solder mask color based on aesthetic and functional preferences. Additionally, Our capability includes a range of surface finish options such as bare copper, HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), immersion tin, immersion silver, pure gold, ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold), and more. This provides flexibility in selecting the most suitable surface finish based on solderability, corrosion resistance, and overall PCB performance requirements. PCB Capability (TMM3) PCB Material: Ceramic, Hydrocarbon, Thermoset Polymer Composites Designation: TMM3 Dielectric constant: 3.27 Layer count: Double Layer, Multilayer, Hybrid PCB Copper weight: 0.5oz (17 µm), 1oz (35µm), 2oz (70µm) PCB thickness: 15mil (0.381mm), 20mil (0.508mm), 25mil (0.635mm), 30mil(0.762mm), 50mil (1.27mm), 60mil (1.524mm), 75mil(1.905mm), 100mil (2.54mm), 125mil (3.175mm), 150mil (3.81mm), 200mil (5.08mm), 250mil (6.35mm), 275mil (6.985mm), 300mil (7.62mm), 500mil (12.7mm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Yellow, Red etc. Surface finish: Bare copper, HASL, ENIG, OSP, Immersion tin, Immersion silver, Pure gold, ENEPIG etc.. TMM3 PCB and Its Applications Presented before you is a visually striking double-sided TMM3 PCB, skillfully constructed on a robust 150mil substrate, featuring a flawless immersion gold surface finish. Rogers TMM3 Microwave PCBs find extensive applications in various industries. They are perfect for RF and microwave circuitry, power amplifiers and combiners, filters and couplers, satellite communication systems, Global Positioning Systems (GPS) antennas, patch antennas, dielectric polarizers and lenses, as well as chip testers Final Rogers TMM3 laminates offer exceptional properties such as low thermal coefficient of dielectric constant, closely matched coefficients of thermal expansion to copper, low etch shrinkage values, and high thermal conductivity. These characteristics make TMM3 laminates advantageous for producing high reliability PCBs with excellent thermal management capabilities. This conclude today’s episode. Thanks for reading. See you next time.