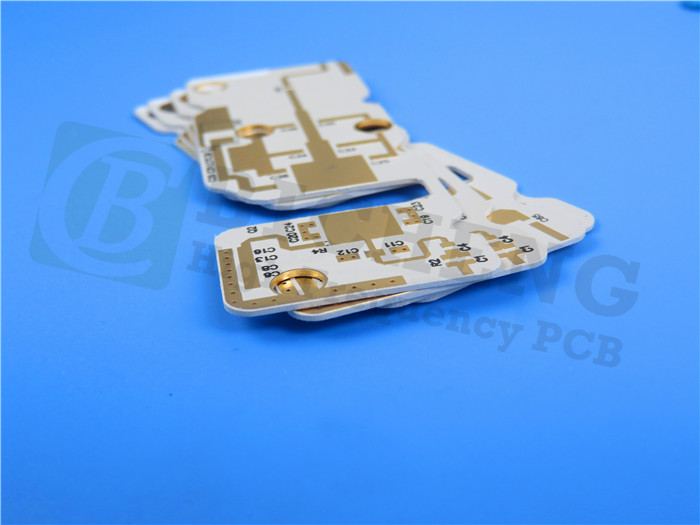

RO3003G2 High Frequency PCB Material Introduction Hello and welcome back to our channel. Today we’ll discussing an extension of Rogers’ highly regarded RO3003 solutions: the RO3003G2 PCB. Rogers RO3003G2 laminates, a high-frequency ceramic-filled PTFE material, build upon the success of Rogers' renowned RO3003 solutions. These laminates have been developed based on industry feedback to specifically cater to the evolving requirements of millimeter wave automotive radar applications. It is engineered with an optimal combination of resin and filler content, resulting in reduced insertion loss. This makes it highly suitable for integration into Advanced Driver Assistance Systems (ADAS) such as adaptive cruise control, forward collision warning, active braking, and lane change assist. RO3003G2 laminate possesses several key properties, each characterized by its typical value. Let's explore these parameters further. Data sheet Here’s the data sheet. RO3003G2 laminate exhibits a dielectric constant of 3.00 ± 0.04 at 10 GHz and 23°C, as per the IPC-TM-650 2.5.5.5 Clamped Stripline test method. The laminate's design dielectric constant is approximately 3.07 which is determined at a frequency of 77 GHz, employing the Differential Phase Length Method. The dissipation factor of the RO3003G2 material is impressively low, measuring at 0.0011 at 10 GHz and 23°C according to the IPC-TM-650 2.5.5.5 test method. This low dissipation factor ensures efficient signal transmission and minimizes energy loss in high-frequency applications. RO3003G2 material demonstrates a thermal coefficient of er of -35 ppm/°C at 10 GHz over a temperature range of -50 to 150°C, as per the IPC-TM-650 2.5.5.5 standard. This parameter indicates the material's stability and performance across varying temperatures. RO3003G2 material demonstrates a thermal coefficient of er of -35 ppm/°C at 10 GHz over a temperature range of -50 to 150°C, as per the IPC-TM-650 2.5.5.5 standard. This parameter indicates the material's stability and performance across varying temperatures. RO3003G2 showcases a volume resistivity of 1.4 x 10^9 MΩ cm under COND A conditions, as per IPC 2.5.17.1. It demonstrates a surface resistivity of 2.6 x 10^8 MΩ under COND A conditions, as per IPC 2.5.17.1. and a tensile modulus of 378-396 ksi in the X and Y directions at 23°C, following ASTM D638. RO3003G2 exhibits a very low moisture absorption rate of 0.06% as per the D48/50 test method of IPC-TM-650 2.6.2.1. The specific heat ranges from 0.73 to 0.83 J/g/K between 0°C and 50°C, as per ASTM E1269-11 test method. Rogers RO3003G2 has a thermal conductivity of 0.43 W/m/K at 50°C, according to ASTM D5470 test method. The laminate exhibits a coefficient of thermal expansion of 16 ppm/°C in the X direction, 17 ppm/°C in the Y direction, and 18 ppm/°C in the Z direction at 23°C, 50% relative humidity, as per IPC-TM-650 2.4.41. Ogers RO3003G2 material has a decomposition temperature (Td) of 500°C as per the TGA test, following ASTM D3850. It exhibits a density of 2.15 gm/cm3 at 23°C, as per ASTM D792. The copper peel strength measures 12.0 lb/in for 1/2 oz electro-deposited copper after solder float, according to IPC-TM-2.4.8. RO3003G2 is classified as V-0,, indicating its high flame resistance, as per the UL 94 standard. Lastly, it is compatible with lead-free processes, ensuring compliance with environmental regulations. PROPERTY RO3003G2 Direction Unit Condition Test Method Dielectric Constant, er Process 3.00 ± 0.04 Z - 10 GHz 23°C IPC-TM-650 Dielectric Constant, er Design 3.07 Z - 77 GHZ Differential Phase Dissipation Factor, tan d 0.0011 Z - 10 GHz 23°C IPC-TM-650 Thermal Coefficient of er -35 Z ppm/°C 10 GHz IPC-TM-650 Dimensional Stability -0.16 X mm/m Method C IPC TM-650 2.2.4 Volume Resistivity 1.4 x 10^9 - MΩ•cm COND A IPC 2.5.17.1 Surface Resistivity 2.6 x 10⁸ - MΩ COND A IPC 2.5.17.1 Tensile Modulus 378 X ksi 23°C ASTM D638 Moisture Absorption 0.06 - % D48/50 IPC-TM-650 Specific Heat 0.73 Z J/g/K 0°C ASTM E1269-11 Thermal Conductivity 0.43 Z W/m/K 50°C ASTM D5470 Coefficient of Thermal Expansion 16 X ppm/°C 23°C/50% RH IPC-TM-650 2.4.41 Td 500 - °CTGA - ASTM D3850 Density 2.15 - gm/ 23°C ASTM D792 Copper Peel Strength 12.0 - lb/in 1/2 oz. EDC IPC-TM-2.4.8 Flammability V-0 - - - UL 94 Lead Free Process Compatible YES - - - - Our PCB Capability( RO3003G2) We offer flexibility in layer count, allowing you to choose from single-sided, double-sided, multi-layer PCBs, or hybrid PCBs. This allows for greater design complexity and functionality. You can select from two copper weight options: 1oz (35μm) and 2oz (70μm). Copper weight determines the thickness and conductivity of the copper layers, providing flexibility to meet your specific needs. We offer dielectric thickness options of 5mil (0.127mm) and 10mil (0.254mm). The dielectric thickness affects the overall thickness and electrical characteristics of the PCB, allowing you to customize it according to your requirements. Our manufacturing capability supports PCB sizes up to a maximum of 400mm x 500mm. This provides ample space for your circuit design and allows for larger or more complex PCB layouts. We offer a range of solder mask colors to choose from, including green, black, blue, yellow, red, and more. Solder mask provides insulation and protection for the PCB, enhancing its durability and reliability. Our RO3003G2 PCBs can be finished with various surface treatments to protect the copper traces and pads. You can choose from options such as immersion gold, Hot Air Solder Leveling, immersion silver, immersion tin, Electroless Nickel Electroless Palladium Immersion Gold, Organic Solderability Preservative, bare copper and pure gold etc. PCB Capability (RO3003G2) PCB Material: Ceramic-filled PTFE Laminates Designation: RO3003G2 Dielectric constant: 3 Dissipation factor 0.0011 Layer count: Single Sided, Double Sided, Multi-layer PCB, Hybrid PCB Copper weight: 1oz (35µm), 2oz (70µm) Dielectric thickness 5mil (0.127mm), 10mil (0.254mm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Yellow, Red etc. Surface finish: Immersion gold, HASL, Immersion silver, Immersion tin, ENEPIG, OSP, Bare copper, Pure gold etc.. RO3003G2PCB and Typical Applications The screen shows a 10mil RO3003G2 PCB with immersion gold coating, specifically used for blind spot detection. Rogers RO3003G2 PCBs are commonly employed in various applications such as adaptive cruise control, forward collision warning, active brake assist, lane change assist, traffic jam pilot, and parking pilot, among others. Final (Multilayer Adhesive System) Rogers RO3003G2 PCB materials are compatible with manufacturing processes for double-sided and multilayer circuits using PTFE materials. They are also compatible with a wide range of adhesive systems, including thermosetting options like FR-4, Rogers' 2929 bondply, RO4400 prepreg, and thermoplastic options such as 3001 Bonding Film, FEP, 3908, PFA, PTFE, etc. Well, this concludes today’s episode. Thank you for reading. I’ll see you next time.

2.5.5.5

Clamped Stripline

Length Method

2.5.5.5

-50 to 150°C

2.5.5.5

-0.14

Y

396

Y

2.6.2.1

0.83

50°C

17

18

Y

Z

cm3

After Solder Float