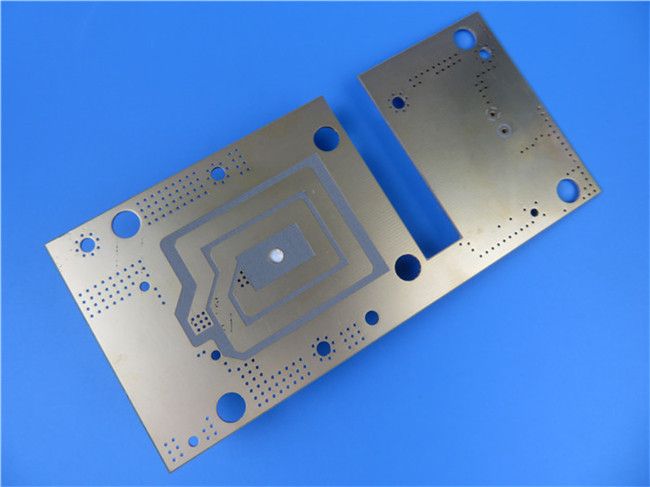

RF-35 High Frequency PCB Material Introduction Hello everyone, Welcome back to our channel. My name is Jane, the regional sales manager for Bicheng PCB. Today, we’re going to talk about a type of organic-ceramic laminate from Taconic's ORCER family --- RF-35. Taconic RF-35 laminates are PTFE-based with woven glass reinforcement. It is the consequence of Taconic's proficiency in coated PTFE fiberglass and ceramic fill technologies. Let’s have a look at the properties of RF-35 substrate. RF-35 Typical Properties Taconic RF-35 laminate has a dielectric constant of 3.50 at 1.9 GHz, with a dissipation factor of 0.0018 at the same frequency. Its moisture absorption is only 0.02% at .060 inch, and it has a peel strength greater than 8.0 lbs./linear inch for 1/2 oz. copper and greater than 10.0 lbs./linear inch for 1 oz. copper, as measured by IPC-TM 650 2.4.8. Taconic RF-35 PCB material also has a dielectric breakdown of 41 kV, volume resistivity of 1.26 x 10^9 Mohm/cm, and surface resistivity of 1.46 x 10^8 Mohm, as measured by IPC-TM 650 2.5.6 and IPC-TM 650 2.5.17.1, respectively. RF-35 laminate has an arc resistance of greater than 180 seconds, as measured by IPC TM 650 2.5.1. Its flexural strength lengthwise and crosswise are greater than 22,000 psi and greater than 18,000 psi, respectively, as measured by ASTM D 790. The tensile strength lengthwise and crosswise are measured at 27,000 psi (or 187 N/mm^2) and 21,000 psi (or 145 N/mm^2), respectively, as measured by ASTM D 638. RF-35 laminate has a dimensional stability of 0.00004 in/in lengthwise and a dimensional stability of -0.00010 in/in crosswise, as measured by IPC-TM 650 2.4.39. RF-35 is high Tg materials, with value of greater than 315°C. RF-35 material has a thermal conductivity of 0.24 W/m/K, as measured by ASTM F 433. Its X-Y CTE is measured between 19-24 ppm/°C, while its Z CTE is measured at 64 ppm/°C, as measured by ASTM D 3386 (TMA). Taconic RF-35 PCB material is also rated V-0 for flammability, as measured by UL-94, and has a hardness of 34% on the Rockwell M scale. Property Test Method Unit Value Unit Value Dielectric Constant @ 1.9 GHz IPC-TM 650 2.5.5 3.5 3.5 Dissipation Factor @ 1.9 GHz IPC-TM 650 2.5.5 0.0018 0.0018 Moisture Absorption (.060") IPC-TM 650 2.6.2.1 % 0.02 % 0.02 Peel Strength (1/2 oz. copper) IPC-TM 650 2.4.8 lbs./linear inch >8.0 N/mm >1.5 Peel Strength (1 oz. copper) IPC-TM 650 2.4.8 lbs./linear inch >10.0 N/mm >1.8 Dielectric Breakdown IPC-TM 650 2.5.6 kV 41 kV 41 Volume Resistivity IPC-TM 650 2.5.17.1 Mohm/cm 1.26 x 109 Mohm/cm 1.26 x 109 Surface Resistivity IPC-TM 650 2.5.17.1 Mohm 1.46 x 108 Mohm 1.46 x 108 Arc Resistance IPC TM 650 2.5.1 seconds >180 seconds >180 Flexural Strength Lengthwise ASTM D 790 psi >22,000 N/mm2 >152 Flexural Strength Crosswise ASTM D 790 psi >18,000 N/mm2 >124 Tensile Strength Lengthwise ASTM D 638 psi 27,000 N/mm2 187 Tensile Strength Crosswise ASTM D 638 psi 21,000 N/mm2 145 Dimensional Stability Lengthwise IPC-TM 650 2.4.39 in/in 0.00004 mm/mm 0.00004 Dimensional Stability Crosswise IPC-TM 650 2.4.39 in/in -0.0001 mm/mm -0.0001 Tg TMA °C >315 °F >600 Thermal Conductivity ASTM F 433 W/m/K 0.24 W/m/K 0.24 X-Y CTE ASTM D 3386 (TMA) ppm/°C 19-24 ppm/°C 19-24 Z CTE ASTM D 3386 (TMA) ppm/°C 64 ppm/°C 64 Flammability UL-94 V-0 V-0 Hardness Rockwell M Scale 34 34 PCB Capability (RF-35) Let’s see our PCB capability on Taconic RF-35 PCB material. We can provide Taconic RF-35 PCB with single layer, double layer, multi-layer and hybrid types, with standard dielectric thicknesses of 10 mils, 20 mils, 30 mils, and 60 mils. The finished copper thickness options are 1oz and 2oz. We can offer PCBs up to a maximum size of 400 mm by 500 mm. This can be a single board in the panel or a panel with multiple alternative designs. Solder mask of green, black, blue and yellow etc is available in house. Various options for plating pads are provided, including immersion gold, HASL, immersion silver, immersion tin, OSP, pure gold, and bare copper etc. Various options for plating pads are provided, including immersion gold, HASL, immersion silver, immersion tin, OSP, pure gold, and bare copper etc. PCB material: PTFE Ceramic Fiberglass Designation: RF-35 Dielectric constant: 3.5 Dissipation factor 0.0018 Layer count: Single layer, Double layer, Multilayer, Hybrid PCB Copper weight: 1oz (35µm), 2oz (70µm) Laminate thickness: 10mil (0.254mm), 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Red, Yellow etc. Surface finish: Immersion gold, HASL, Immersion silver, Immersion tin, OSP, Pure gold, Bare copper, ENEPIG etc.. A Piece of RF-35 PCB On the screen is a type of 60mil RF-35 PCB with immersion gold for power amplifiers. We can also find its applications in passive components, filters and couplers etc. Conclusion Due to the softness of the PTFE resin system, machining of PTFE-based substrates is often more challenging than machining of epoxy-based substrates. The type of fiberglass utilized in the substrate has an impact on the quality of routing with respect to burrs and fibers. The heavier the fiberglass weave, the more difficult it is to cut. Taconic RF-35 PCB employs a heavy weight 7628 glass style, which offers good dimensional stability and rigidity but is typically more challenging to drill or rout compared to the product which uses a medium weight glass style. OK. This concludes the episode. Thank you for your reading. See you next time.