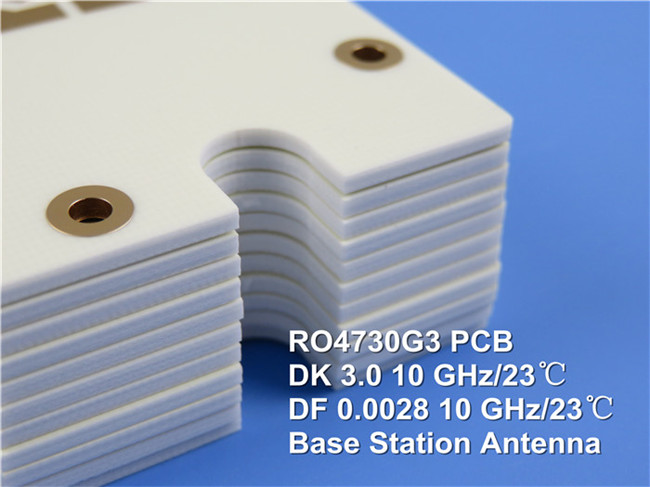

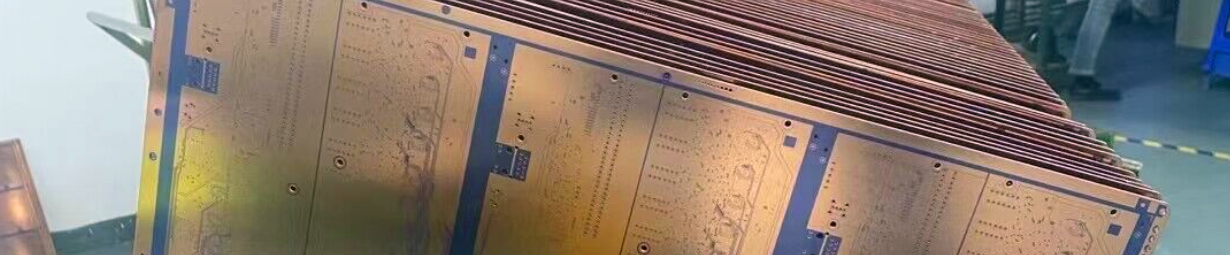

Rogers R04730G3 High Frequency PCB Material Introduction Hello everyone. Welcome back to our channel. Today, we’re going to talk about a type of antenna grade high frequency PCB---Rogers RO4730G3 high frequency PCB. Rogers’ RO4730G3 high frequency PCB materials are reliable antenna-grade laminates, fully compatible with conventional FR-4 and high temperature lead-free solder processing. They are an affordable low-cost alternative material to conventional PTFE-based antenna substrates, allowing for designers to optimize cost and performance. RO4730G3 Typical Properties Rogers RO4730G3 is a high-performance PCB material that offers outstanding characteristics for various applications. Let's take a closer look at its key properties. RO4730G3 laminate exhibits a dielectric constant of 3.0±0.5 in the process and 2.98 in the design, making it an excellent choice for high-frequency applications ranging from 1.7 GHz to 5 GHz. With a low tanδ value of 0.0028, the RO4730G3 minimizes energy loss and ensures efficient signal transmission even at 10 GHz. The thermal coefficient of dielectric constant, at +34 ppm/℃, allows the RO4730G3 to maintain stable electrical performance over a wide temperature range, from -50 ℃ to 150℃. Ideally, TCDk should be 0 ppm / ℃. In other words, Dk does not change with temperature. So, as a digital reference, a TCDk less than | 50 | ppm / ℃ or lower can be considered better. Dimensional stability is crucial for consistent performance. The RO4730G3 demonstrates exceptional stability, with a maximum change of less than 0.4 mm/m in the X and Y directions even after exposure to high temperatures during etching processes. RO4730G3 exhibits a volume resistivity of 9 X 10^7 MΩ.cm under COND A conditions, with a thickness of 0.030", following IPC-TM-650 2.5.17.1, indicating its excellent electrical insulation properties. With a surface resistivity of 7.2 X 10^5 MΩ under COND A conditions and a thickness of 0.030", according to IPC-TM-650 2.5.17.1, the material offers effective surface insulation against electrical currents. RO4730G3 displays a remarkably low level of passive intermodulation (PIM) at -165 dBc, when tested under specific conditions of 50 ohm, 0.060" size, and 43 dBm power at 1900 MHz, suggesting minimal interference or distortion in wireless communication applications. Rogers company has made a general classification of the intermodulation: when the intermodulation value reaches -143dBc, it is the better intermodulation. It is very good when the intermodulation value reaches -153dBc and excellent intermodulation when the value reaches -163dBc. We can see that RO4730G3 materials exhibit excellent PIM performance. Rogers RO4730G3 laminate exhibits impressive electrical strength, with a value of 730 V/mil, ensuring reliable insulation properties. In terms of mechanical strength, it has a flexural strength of 181 Mpa (26.3 kpsi) in the MD direction and 139 Mpa (20.2 kpsi) in the CMD direction. RO4730G3 demonstrates a low moisture absorption of 0.093% (48/50) according to IPC-TM-650 2.6.2.1 and ASTM D570, indicating its resistance to absorbing moisture from the environment. With a thermal conductivity of 0.45 W/mK in the Z direction at 50°C, as measured by ASTM D5470, the material effectively conducts heat, making it suitable for applications requiring efficient thermal management. The coefficient of thermal expansion for RO4730G3 is 15.9 ppm/°C (X), 14.4 ppm/°C (Y), and 35.2 ppm/°C (Z) over a wide temperature range of -50°C to 288°C, based on IPC-TM-650 2.4.4.1. This indicates the material's ability to withstand temperature variations without significant dimensional changes. The CTE in both the X and Y directions are similar to that of copper. The good CTE match reduces stresses in the PCB antennas. Rogers RO4730G3 exhibits a high glass transition temperature (Tg) exceeding 280°C, as determined using IPC-TM-650 2.4.24, indicating its excellent thermal stability even at elevated temperatures. The typical high glass transition temperature leads to a low Z-axis CTE,which also results in excellent plated through hole reliability. With a thermal decomposition temperature (Td) of 411°C, as measured by ASTM D3850, the material can withstand high temperatures without undergoing significant degradation or decomposition. The density of RO4730G3 is 1.58 gm/cm3, as determined by ASTM D792, indicating its relatively lightweight nature while still maintaining sufficient structural integrity. RO4730G3 demonstrates a strong copper peel strength of 4.1 pli when using 1oz, LoPro EDC, according to IPC-TM-650 2.4.8, ensuring reliable adhesion between copper layers in electronic applications. The material has achieved a flammability rating of V-0, meeting the stringent requirements of UL 94, indicating its self-extinguishing properties and high resistance to combustion. RO4730G3 is compatible with lead-free processes, making it suitable for environmentally friendly manufacturing and assembly methods. Property RO4730G3 Direction Units Condition Test Method Dielectric Constant,εProcess 3.0±0.5 Z 10 GHz 23℃ IPC-TM-650 2.5.5.5 Dielectric Constant,εDesign 2.98 Z 1.7 GHz to 5 GHz Differential Phase Length Method Dissipation Factor,tanδ 0.0028 Z 10 GHz 23℃ IPC-TM-650 2.5.5.5 2.5 GHz Thermal Coefficient of ε +34 Z ppm/℃ -50 ℃to 150℃ IPC-TM-650 2.5.5.5 Dimensional Stability <0.4 X, Y mm/m after etech +E2/150 ℃ IPC-TM-650 2.4.39A Volume Resistivity (0.030") 9 X 107 MΩ.cm COND A IPC-TM-650 ?2.5.17.1 Surface Resistivity (0.030") 7.2 X 105 MΩ COND A IPC-TM-650 ?2.5.17.1 PIM -165 dBc 50 ohm 0.060" 43 dBm 1900 MHz Electrical Strength (0.030") 730 Z V/mil IPC-TM-650 2.5.6.2 Flexural Strength MD 181 (26.3) Mpa (kpsi) RT ASTM D790 CMD 139 (20.2) Moisure Absorption 0.093 - % 48/50 IPC-TM-650 2.6.2.1 ASTM D570 Thermal Conductivity 0.45 Z W/mK 50℃ ASTM D5470 Coefficient of Thermal Expansion 15.9 X ppm/℃ -50 ℃to 288℃ IPC-TM-650 2.4.4.1 Tg >280 ℃ IPC-TM-650 2.4.24 Td 411 ℃ ASTM D3850 Density 1.58 gm/cm3 ASTM D792 Copper Peel Stength 4.1 pli 1oz,LoPro EDC IPC-TM-650 2.4.8 Flammability V-0 UL 94 Lead-free Process Compatible Yes PCB capability (RO4730G3) For RO4730G3 PCBs, we can provide you with single layer board, double layer board, multi-layer board and hybrid types. Rogers RO4730G3 PCBs have low profile copper and ED copper with different thickness. LoPro copper has the thickness of 5.7mil, 10.7mil, 20.7mil, 30.7mil and 60.7mil etc. ED copper has the thickness of 20mil, 30mil, 50mil and 60mil etc. Finished copper on PCB, no matter LoPro or ED copper, can be 1oz and 2oz. The maximum PCB size on RO4730G3 substrates is 400mm by 500mm; it can be a single board in the sheet and also can be different designs in this panel. Solder mask of green, black, blue and yellow etc is available in house. There’s immersion gold, HASL, immersion silver, immersion tin, bare copper etc applied to the pads surface finish. PCB Material: Hydrocarbon ceramic woven glass Designation: RO4730G3 Dielectric constant: 3.0 ±0.05 (process) 2.98 (design) Layer count: 1-layer, 2-layer, Multi-layer, Hybrid designs Laminate thickness (low profile copper): 5.7mil(0.145mm), 10.7mil(0.272mm), 20.7mil(0.526mm, 30.7mil(0.780mm), 40.7mil(1.034mm), 60.7mil(1.542mm) Laminate thickness (ED Copper): 20mil(0.508mm), 30mil(0.762mm), 40mil(1.016mm), 50mil(1.270mm), 60mil(1.524mm) Copper weight: 1oz (35 µm), 2oz (70µm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Yellow, Red etc. Surface finish: Immersion gold, HASL, Immersion silver, Immersion tin, Bare copper, OSP, Pure gold, ENEPIG etc. A Piece of RO4730G3 PCB Now what we are seeing on the screen is a type of 60mil RO4730G3 PCB, double-sided with immersion gold for base station antennas. Conclusion In summary, Rogers RO4730G3 presents itself as a highly reliable and versatile material, offering excellent electrical properties, dimensional stability, and thermal performance. Its superior characteristics make it suitable for various applications, including high-frequency circuit boards and other electronic components. Rogers RO4730G3 PCB has the features of low insertion loss, light-weight 30% lighter than PTFE or fiber glass material. Thank you for joining us today as we explored the remarkable features of the RO4730G3 and our printed circuit boards on it. If you have any further questions or would like more information, please don't hesitate to reach out to our team. Thanks for reading. Have a great day!

14.4

35.2

Y

Z