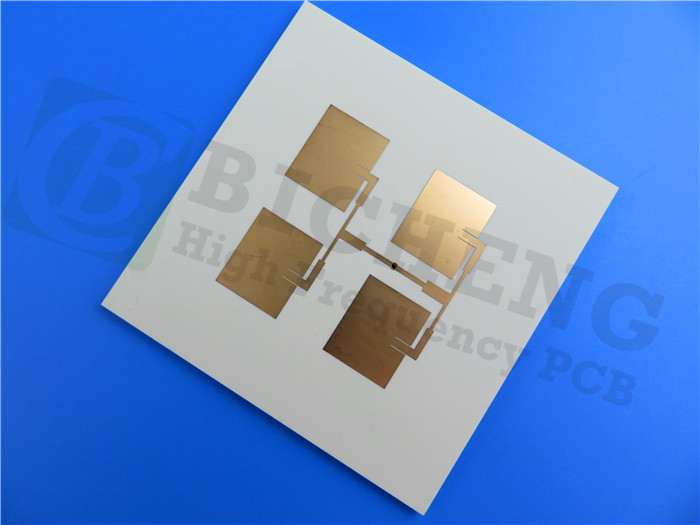

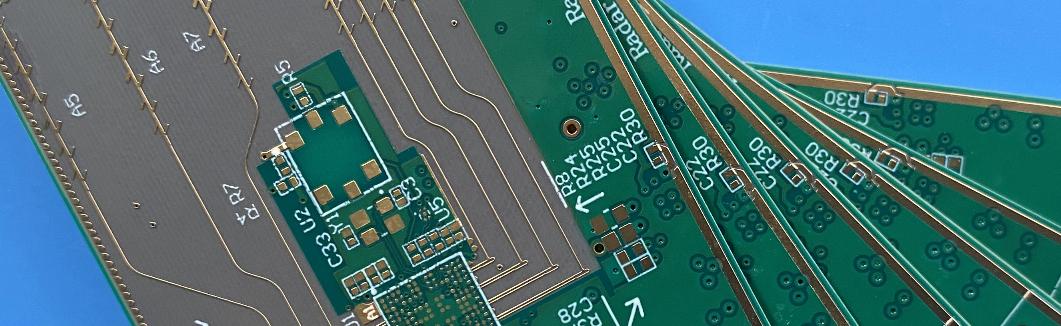

R04533 High Frequency PCB Material Introduction Rogers RO4533 High Frequency Laminates, ceramic-filled, glass-reinforced hydrocarbon based material, are cost/performance materials from Rogers Corporation, specifically engineered and manufactured to meet the specific demands of the antenna markets. It has a dielectric constant of 3.3 and a loss tangent (Df) of 0.0025 measured at 10 GHz. These values allow antenna designers to realize substantial gain values while minimizing signal loss. Thus, it provides excellent passive intermodulation response required for mobile infrastructure microstrip antenna applications. Rogers R04533 High Frequency PCB Material is an affordable alternative to more conventional PTFE antenna technologies, thus allowing our designers to optimize the price and performance of the antennas. The resin systems of RO4533 dielectric materials are designed to provide the necessary properties for ideal antenna performance. The coefficients of thermal expansion (CTEs) in both the X and Y directions are similar to that of copper. The good CTE match reduces stresses in the printed circuit board antenna. Features and Benefits 1. Low Loss 0.0025 , Low Dk 3.3, low PIM response: Wide range of application use 2. Thermoset resin system: Compatible with standard PCB fabrication 3. Excellent dimensional stability: Greater yield on larger panels sizes 4. Uniform mechanical properties: Maintains mechanical form during handling 5. High thermal conductivity: Improved power handling Typical Applications: 1. Cellular infrastructure base station antennas 2. WiMAX antenna networks Our PCB Capabilities (RO4533) PCB Material: Ceramic-filled, Glass-reinforced Hydrocarbon Designation: RO4533 Dielectric constant: 3.3 Dissipation Factor 0.0025 10GHz Layer count: Double Sided PCB, Multilayer PCB, Hybrid PCB Copper weight: 0.5oz (17 μm), 1oz (35μm), 2oz (70μm) Laminate thickness: 20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm ) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Yellow, Red etc. Surface finish: Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP etc.. Typical value of RO4533 Property RO4533 Direction Units Condition Test Method Dielectric Constant, er Process 3.3 ± 0.08 Z - 10 GHz/23℃ 2.5 GHz IPC-TM-650,2.5.5.5 Dissipation Factor 0.002 Z - 2.5 GHz/23℃ IPC-TM-650, 2.5.5.5 0.0025 10 GHz/23℃ PIM (Typical) -157 - dBc Reflected 43 dBm swept tones Summitek 1900b PIM Analyzer Dielectric Strength >500 Z V/mil 0.51 mm IPC-TM-650, 2.5.6.2 Dimensional Stability <0.2 X,Y mm/m (mils/inch) after etch IPC-TM-650, 2.4.39A Coefficient of Thermal Expansion 13 X ppm/℃ -55 to 288℃ IPC-TM-650, 2.4.41 11 Y 37 Z Thermal Conductivity 0.6 - W/(m.K) 80℃ ASTM C518 Moisture Absorption 0.02 - % D48/50 IPC-TM-650, 2.6.2.1 ASTM D570 Tg >280 - ℃ TMA A IPC-TM-650, 2.4.24.3 Density 1.8 - gm/cm3 - ASTM D792 Copper Peel Strength 6.9 (1.2) - lbs/in (N/mm) 1 oz. EDC post solder float IPC-TM-650, 2.4.8 Flammability NON FR - - - UL 94 Lead-Free Process Compatible Yes - - - -