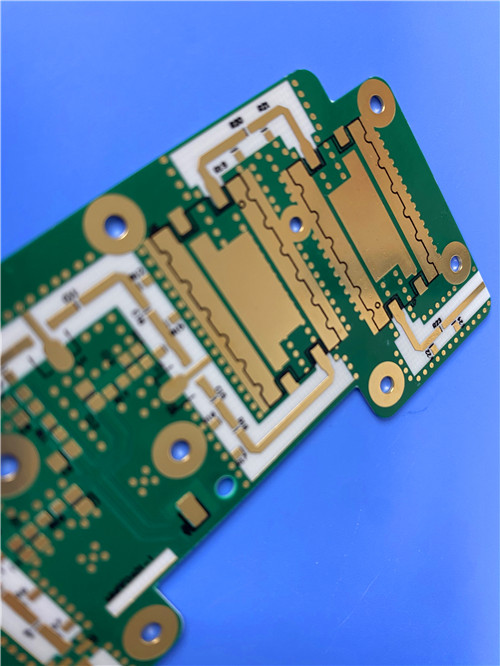

CLTE-AT High Frequency PCB Material Introduction Hello everyone. Today, we'll take an in-depth look at a critical material that excels in high-performance RF and microwave applications: Rogers CLTE-AT high-frequency PCB laminate, and showcase our proven manufacturing capabilities with this advanced substrate. Rogers CLTE-AT is a ceramic-PTFE composite laminate reinforced with woven fiberglass, designed to offer an optimal balance of superior electrical performance, exceptional dimensional stability, and excellent value for commercial applications requiring high reliability. Core Features & Benefits Rogers CLTE-AT high-frequency circuit materials stand out in the commercial marketplace by addressing key challenges in modern RF design: Best-in-Class Low Loss: Achieves outstanding Insertion Loss (S21) performance and an ultralow Loss Tangent (Df) of 0.0013, ensuring minimal signal degradation. Unmatched Stability: Features a Very Low Temperature Coefficient (TCEr) and tight Dielectric Constant (Dk) tolerance of 3.00 ±0.04, providing exceptional electrical phase and impedance stability across a wide temperature range (-55°C to 150°C). Superior Mechanical Robustness: The woven glass reinforcement delivers a high degree of dimensional stability, which is critical for multilayer board registration and reliability. It also offers a low and balanced CTE (8, 8, 20 ppm/°C in X, Y, Z). Enhanced Thermal & Processing Advantages: With a thermal conductivity of 0.64 W/m/K, it improves heat dissipation. Its design ensures strong, reliable copper adhesion without relying on lossy, rough copper foils, and it features low moisture absorption (0.03%). CLTE-AT Material Properties The following table summarizes the key physical and electrical properties that make CLTE-AT a good choice: Property Category Key Parameter Typical Value/Condition Unit/Standard Electrical Dielectric Constant (Dk) 3.00 ±0.04 @ 10 GHz IPC-TM-650 Dissipation Factor (Df) 0.0013 @ 10 GHz IPC-TM-650 Thermal Thermal Conductivity 0.64 W/m·K Coefficient of Thermal Expansion (CTE) 8, 8, 20 (X, Y, Z) ppm/°C Operating Temperature -55 to +150 °C Mechanical/Physical Moisture Absorption 0.03 % (IPC-2.6.2.1) Flammability Rating UL 94 V-0 - Dimensional Stability Excellent (Woven Glass) - Copper Peel Strength High (No Na Treatment Needed) - Typical Capabilities of CLTE-AT 2-Layer PCBs At Bicheng PCB, we have extensive experience processing CLTE-AT laminates into high-quality, reliable printed circuit boards. Here is a snapshot of our standard manufacturing specs for a typical CLTE-AT double-layer board: Specification Category Manufacturing Parameter Capability/Detail Board Construction Base Material Rogers CLTE-AT Layer Count Double-Sided (2-Layer Rigid) Critical Dimensions Board Thickness 0.2 mm (Finished) Min. Trace/Space 4 / 6 mils Min. Hole Size 0.3 mm Finished Cu Weight 1 oz (35 µm) Processing & Quality Surface Finish Immersion Gold (ENIG) Solder Mask (Top) Green Via Plating Thickness 20 µm (Minimum) Electrical Test 100% Netlist Test Quality Standard IPC-A-600 Class 2 Note: The above is based on a standard build. We support customization including different layer counts, hybrid builds, various surface finishes (HASL, Immersion Silver, OSP), and solder mask colors. A PCB and Typical Applications The unique property set of CLTE-AT PCB material makes it the ideal substrate for advanced, stability-sensitive applications: Automotive Radar Systems (e.g., Adaptive Cruise Control, Collision Avoidance) Phase and Temperature-Sensitive Antenna Arrays High-Performance RF/Microwave Filters and Diplexers Critical Aerospace & Defense Communications Electronics Conclusion Rogers CLTE-AT PCB laminates provide a commercially astute solution that does not compromise on performance. By delivering an exceptional combination of low loss, outstanding stability, and reliable manufacturability, CLTE-AT circuit board enables the next generation of compact, high-frequency devices. Ready to leverage CLTE-AT for your next project? At Bicheng PCB, we combine advanced materials like CLTE-AT with our precision manufacturing expertise to turn complex RF designs into reality. Contact us today to discuss your specific requirements and receive a quote. Thank you for reading. We look forward to supporting your innovation.