Home

-

High Temperature PCB

-

IT-180ATC High Tg PCB 0.6mm-3.2mm High Reliability Lead Free PCB with ENIG,ENEPIP and Pure gold

Home

-

High Temperature PCB

-

IT-180ATC High Tg PCB 0.6mm-3.2mm High Reliability Lead Free PCB with ENIG,ENEPIP and Pure gold

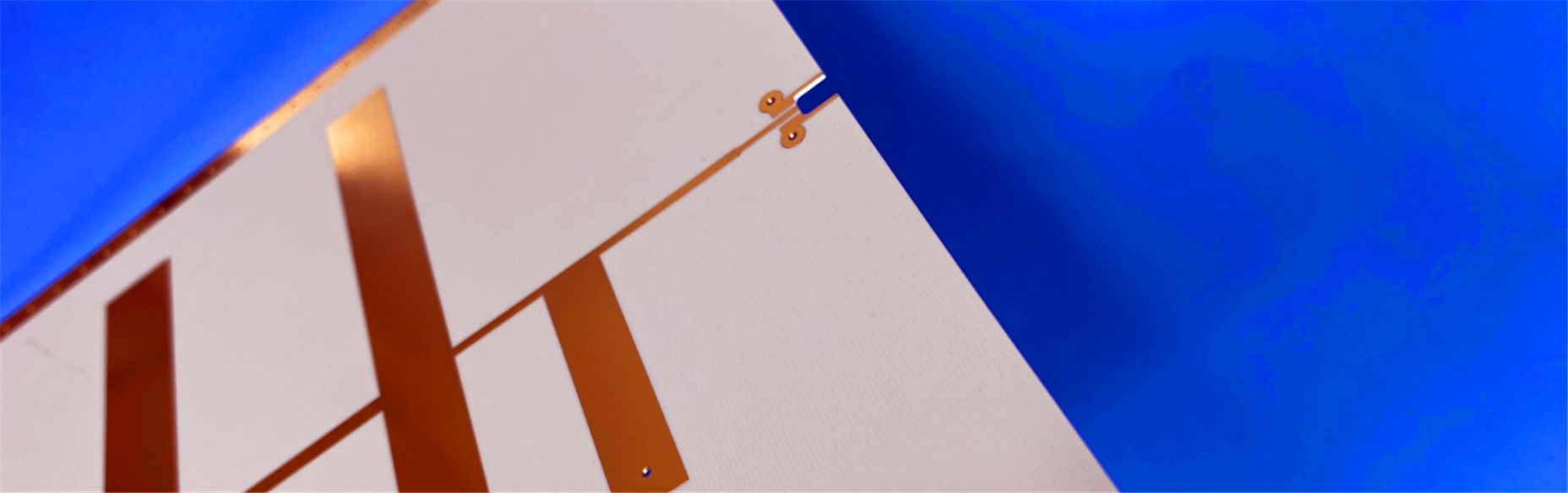

IT-180ATC High Tg PCB 0.6mm-3.2mm High Reliability Lead Free PCB with ENIG,ENEPIP and Pure gold

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

General Description

IT-180ATC PCB is an advanced high-Tg (175℃ via DSC) multifunctional filled epoxy circuit board, featuring high thermal reliability and CAF resistance. It is suitable for a variety of applications and can withstand 260℃ lead-free assembly processes. Its thickness ranges from 0.5mm to 3.2mm, and the copper weight ranges from 0.5oz to 3oz.

.jpg)

Applications

Automotive (Engine room ECU)

Multilayer and HDI PCB

Backplanes

Data Storage

Server and Networking

Telecommunications

Heavy Copper

Key Features

Low CTE

High heat resistance

Excellent CAF resistance

Good through-hole reliability

Our PCB Capability (IT-180ATC)

Our PCB Capability (IT-180ATC) |

|

PCB Material: |

High Tg, Lead Free High Reliability Epoxy Resin |

Designation: |

IT-180ATC |

Dielectric constant: |

4.4 at 1GHz |

Layer count: |

Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm), 3oz (105µm) |

PCB thickness: |

0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.6mm, 1.8mm, 2.0mm, 2.4mm, 3.0mm, 3.2mm |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Matt Black, Blue, Matt Blue, Yellow, Red, Purple etc. |

Surface finish: |

Bare copper, HASL, ENIG, OSP, Immersion tin, Immersion Silver, ENEPIG, Pure gold etc.. |

Technology: |

HDI, Via in pad, Impedance Control, Blind via/Buried via, Edge Plating, BGA, Countsunk Holes etc. |

General Properties of IT-180ATC

| General Properties | |||

| Items | IPC TM-650 | Typical Value | Unit |

| Peel Strength, minimum | 2.4.8 | lb/inch | |

| A. Low profile copper foil | 5 | ||

| B. Standard profile copper foil | 8 | ||

| Volume Resistivity | 2.5.17.1 | 1x109 | M-cm |

| Surface Resistivity | 2.5.17.1 | 1x108 | M |

| Moisture Absorption, maximum | 2.6.2.1 | 0.1 | % |

| Permittivity (Dk, 50% resin content) | -- | ||

| A. 1MHz | 2.5.5.9 | 4.5 | |

| B. 1GHz | 2.5.5.9 | 4.4 | |

| Loss Tangent (Df, 50% resin content) | -- | ||

| A. 1MHz | 2.5.5.9 | 0.014 | |

| B. 1GHz | 2.5.5.9 | 0.015 | |

| Flexural Strength, minimum | N/mm2 | ||

| A. Length direction | 2.4.4 | 500-530 | |

| B. Cross direction | 410-440 | ||

| Thermal Stress 10 s at 288°C | |||

| A. Unetched | 2.4.13.1 | Pass | Rating |

| B. Etched | Pass | ||

| Flammability | UL94 | V-0 | Rating |

| Comparative Tracking Index (CTI) | IEC 60112 / UL 746 | CTI 3 (175-249) | Class (Volts) |

| Glass Transition Temperature(DSC) | 2.4.25 | 175 | ˚C |

| Decomposition Temperature | 2.4.24.6 | 345 | ˚C |

| X/Y Axis CTE (40℃ to 125℃) | 2.4.41 | 11-13 / 13-15 | ppm/˚C |

| Z-Axis CTE | |||

| A. Alpha 1 | 45 | ppm/˚C | |

| B. Alpha 2 | 2.4.24 | 210 | ppm/˚C |

| C. 50 to 260 Degrees C | 2.7 | % | |

| Thermal Resistance | |||

| A. T260 | 2.4.24.1 | >60 | Minutes |

| B. T288 | 20 | Minutes |