Home

-

High Temperature PCB

-

4-layer TU-872 SLK Sp HDI PCB High Tg Material Featuring Blind Vias and Buried Vias with Immersion Gold

Home

-

High Temperature PCB

-

4-layer TU-872 SLK Sp HDI PCB High Tg Material Featuring Blind Vias and Buried Vias with Immersion Gold

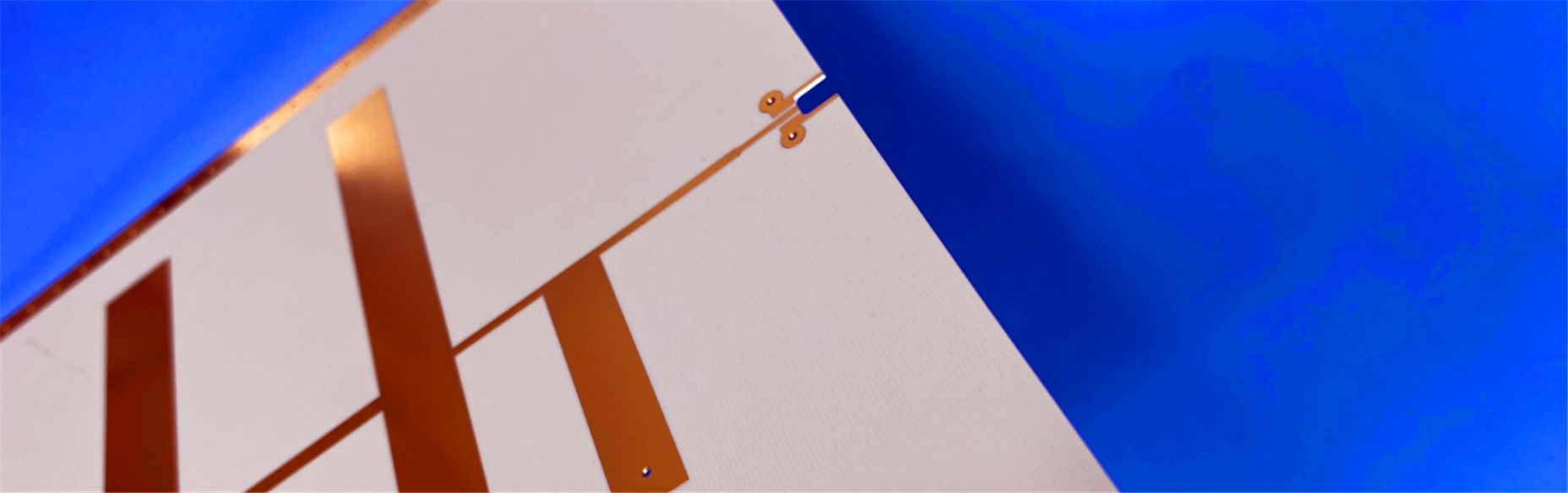

4-layer TU-872 SLK Sp HDI PCB High Tg Material Featuring Blind Vias and Buried Vias with Immersion Gold

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

Brief Introduction

This 4-layer TU-872 SLK Sp PCB utilizes low Dk/Df FR-4 material with 1oz copper on each layer, finished with immersion gold surface treatment and green solder mask. TU-872 PCB has a final thickness of 1.6mm (±10%) and is arrayed in a panel of 16 units. It incorporates HDI technology featuring blind vias from the top layer to inner layer 1 and buried vias between inner layers 1 and 2. Manufactured to IPC-Class-2 standards, each board is vacuum-sealed for secure shipment.

.jpg)

PCB Specifications

| Item | Description | Requirement | Actual | Result |

| 1. Laminate | Material Type | FR-4 TU-872 SLK Sp | FR-4 TU-872 SLK Sp | ACC |

| Tg | 170℃ | 170℃ | ACC | |

| Supplier | TU | TU | ACC | |

| Thickness | 1.6±10% mm | 1.61-1.62mm | ACC | |

| 2.Plating thickness | Hole Wall | ≥25µm | 26.51µm | ACC |

| Outer copper | 35µm | 40.21µm | ACC | |

| Inner Copper | 30µm | 31.15µm | ACC | |

| 3.Solder mask | Material Type | Kuangshun | Kuangshun | ACC |

| Color | Green | Green | ACC | |

| Rigidity (Pencil Test) | ≥4H or above | 5H | ACC | |

| S/M Thickness | ≥10 µm | 19.55µm | ACC | |

| Location | Both Sides | Both Sides | ACC | |

| 4. Component Mark | Material Type | TAIYO/ IJR-4000 MW300 | IJR-4000 MW300 | ACC |

| Color | White | White | ACC | |

| Location | C/S, S/S | C/S, S/S | ACC | |

| 5. Vias | Therough holes | YES | L1-L4 | ACC |

| Blind vias | YES | L1-L2 | ACC | |

| Buried vias | YES | L2-L3 | ACC | |

| 6. Identification | UL Mark | YES | YES | ACC |

| Date Code | WWYY | 0421 | ACC | |

| Mark Location | Solder Side | Solder Side | ACC | |

| 7. Surface Finish | Method | Immersion Gold | Immersion Gold | ACC |

| Tin Thickness | ||||

| Nickel Thickness | 3-6µm | 5.27µm | ACC | |

| Gold Thickness | 0.05µm | 0.065µm | ACC | |

| 8. Normativeness | RoHS | Directive 2015/863/EU | OK | ACC |

| REACH | Directive 1907 /2006 | OK | ACC | |

| 9.Annular Ring | Min. Line Width (mil) | 7mil | 6.8mil | ACC |

| Min. Spacing (mil) | 6mil | 6.2mil | ACC | |

| 10.V-groove | Angle | 30±5º | 30º | ACC |

| Residual thickness | 0.4±0.1mm | 0.38mm | ACC | |

| 11. Beveling | Angle | |||

| Height | ||||

| 12. Function | Electrical Test | 100% PASS | 100% PASS | ACC |

| 13. Appearance | IPC Class Level | IPC-A-600J &6012D Class 2 | IPC-A-600J &6012D Class 2 | ACC |

| Visual Inspection | IPC-A-600J &6012D Class 2 | IPC-A-600J &6012D Class 2 | ACC | |

| Warp and Twist | ≦0.7% | 0.32% | ACC | |

| 14. Reliability Test | Tape Test | No Peeling | OK | ACC |

| Solvent Test | No Peeling | OK | ACC | |

| Solderability Test | 265 ±5℃ | OK | ACC | |

| Thermal Stress Test | 288 ±5℃ | OK | ACC | |

| Ionic Contamination Test | ≦ 1.56 µg/c㎡ | 0.58µg/c㎡ | ACC |

Typical Applications

1. Radio Frequency

2. Backpanel, High performance computing

3. Line cards, Storage

4. Servers, Telecom, Base station

5. Office Routers

High Tg PCB

The thermal performance of a resin system is characterized by its glass transition temperature (Tg), which is always expressed in °C. The most commonly referenced thermal property is thermal expansion. When measuring thermal expansion against temperature, an expansion curve (as shown in the following figure) can be obtained. The Tg value is determined by the intersection of the tangent lines of the flat and steep segments of this curve.

Below the glass transition temperature, epoxy resin exhibits a rigid, glass-like state. Once the temperature exceeds Tg, the resin transitions to a soft, rubbery state.

Tg of Common Epoxy Resins and Soldering Risks

For the most widely used epoxy resins (FR-4 grade), the glass transition temperature typically ranges from 115°C to 130°C. This means the Tg is easily exceeded during PCB soldering processes.

When the board temperature surpasses Tg, two key changes occur:

The PCB expands in the Z-axis direction, creating stress on the copper layer of the hole walls.

The thermal expansion rate of epoxy resin becomes 15 to 20 times that of copper, significantly increasing the risk of plated-through hole (PTH) wall cracking. The more resin surrounding the hole wall, the higher this risk.

In contrast, below Tg, the expansion rate ratio between epoxy resin and copper is only 3:1, making the risk of cracking negligible.

Definition of High Tg PCB

General PCB: Tg ≥ 130°C

Medium Tg PCB: Tg ≥ 150°C

High Tg PCB: Tg ≥ 170°C

PCBs with a glass transition temperature of 170°C or higher are generally defined as high Tg PCBs.

Partial High Tg Material in House

Material |

Tg (℃) |

Manufacturer |

S1000-2M |

180 |

Shengyi |

TU-768 |

170 |

TU |

TU-872 SLK Sp |

170 |

TU |

TU-883 |

170 |

TU |

IT-180ATC |

175 |

ITEQ |

KB-6167F |

170 |

KB |

M6 |

185 |

Panasonic |

Kappa 438 |

280 |

Rogers |

RO4350B |

280 |

Rogers |

RO4003C |

280 |

Rogers |

RO4730G3 |

280 |

Rogers |

RO4360G2 |

280 |

Rogers |