Home

-

High frequency PCB

-

Rogers RO4725JXR High Frequency PCB 30.7mil 60.7mil Antenna Grade RF Printed Circuit Board DK 2.55

Home

-

High frequency PCB

-

Rogers RO4725JXR High Frequency PCB 30.7mil 60.7mil Antenna Grade RF Printed Circuit Board DK 2.55

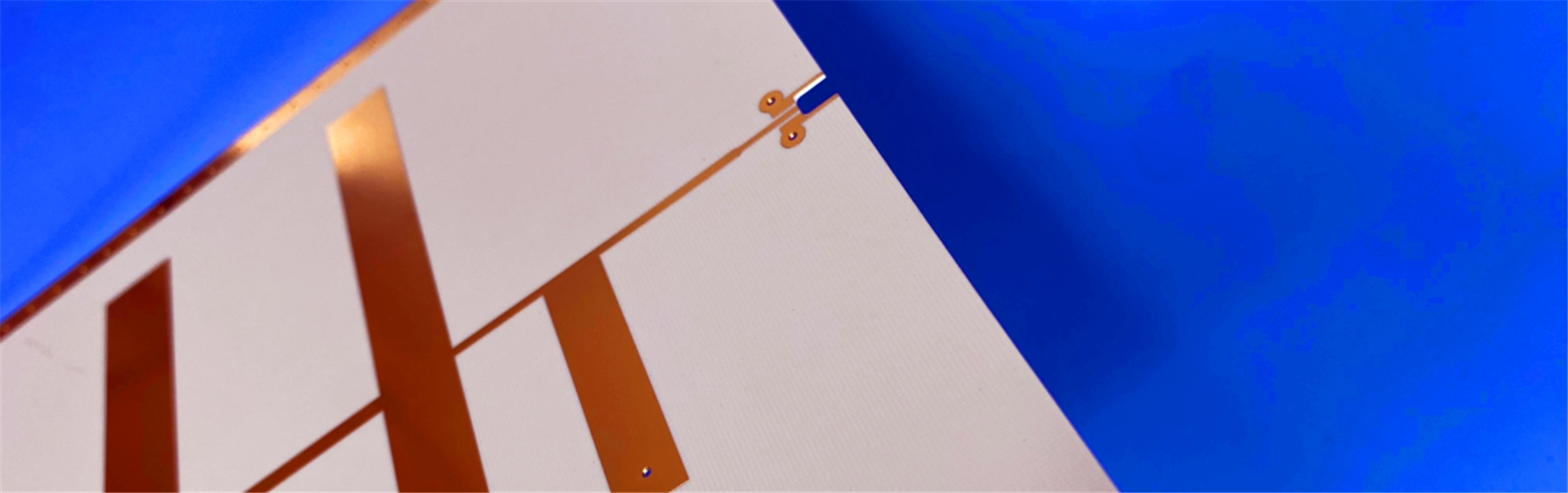

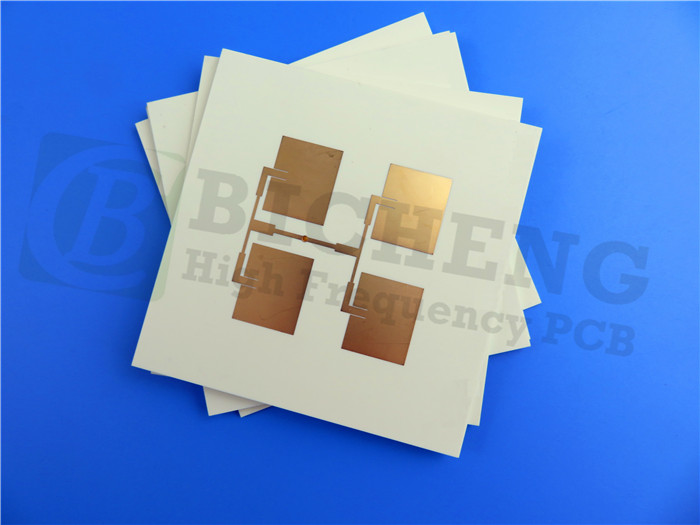

Rogers RO4725JXR High Frequency PCB 30.7mil 60.7mil Antenna Grade RF Printed Circuit Board DK 2.55

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

General Description

Rogers RO4725JXR PCB (antenna grade laminates) provides a dependable and cost-effective substitute for traditional PTFE-based laminates, making it a practical choice for antenna design applications.

The resin systems integrated into RO4725JXR dielectric materials deliver the essential properties needed to ensure optimal antenna performance—this includes characteristics that support signal integrity, stability, and overall functionality critical to antenna operation. Additionally, RO4725JXR antenna grade laminates boast full compatibility with conventional FR-4 processes and high-temperature lead-free solder processes, eliminating the need for specialized manufacturing setups that often increase production complexity.

A key advantage over traditional PTFE-based laminates lies in plated through-hole (PTH) preparation: unlike PTFE alternatives, these RO4725JXR materials do not require special treatment for PTH processing. This not only simplifies the manufacturing workflow but also reduces potential delays or errors associated with extra preparation steps. For designers, selecting RO4725JXR laminates translates to achieving cost-effective solutions—without sacrificing the performance standards required for high-quality antenna systems.

Features:

1.Dielectric constant of 2.55+/- 0.05

2. Low Z-axis coefficient of thermal expansion at 25.6 ppm/°C

3. Low TCDk (Thermal Coefficient of Dielectric Constant) of +34 ppm/°C

4. Dissipation factors ranging from .0022 to .0026

5. High glass transition temperature (Tg) exceeding 280°C

Benefits:

- Low insertion loss, ensuring minimal signal loss during transmission

- Dk (Dielectric Constant) matched to standard PTFE-based antenna offerings, facilitating seamless integration with existing designs

- Reduced passive inter-modulation (PIM), leading to improved signal quality and less interference

- Consistent circuit performance, providing reliable and predictable results.

Our PCB Capability( RO4725JXR)

| PCB Capability (RO4725JXR) | |

| PCB material: | Hydrocarbon / Ceramic / Woven Glass |

| Designation: | RO4725JXR |

| Dielectric constant: | 2.55 |

| Layer count: | Sinlge-sided PCB, Double-sided PCB, Multi-layer PCB, Hybrid PCB |

| Dielectric thickness: | 30.7mil(0.780mm), 60.7mil (1.542mm) |

| Copper weight: | 1oz (35µm), 2oz (70µm) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Red, Yellow, White etc. |

| Surface finish: | Immersion gold, HASL, Immersion silver, Immersion tin, Bare copper, OSP, ENEPIG, Pure gold etc.. |

Typical Applications

Cellular Base Station Antennas

RO4725JXR Typical Properties

| Property | RO4725JXR | Direction | Units | Condition | Test Method |

| Dielectric Constant, εr Process | 2.55 ± 0.05 | Z | 10 GHz/23°C | IPC-TM-650, 2.5.5.5 | |

| Dielectric Constant, εr Design | 2.64 | Z | 1.7 GHz - 5 GHz |

Differential Phase Length Method | |

| Dissipation Factor | 0.0026 | Z | 10 GHz/23°C | IPC-TM-650, 2.5.5.5 | |

| 0.0022 | 2.5GHz | ||||

| Thermal Coefficient of εr | +34 | Z | ppm/°C | -50°C to 150°C | IPC-TM-650, 2.5.5.5 |

| Volume Resistivity (0.030"") | 2.16 X 10^8 | MΩ•cm | COND A | IPC-TM-650, 2.5.17.1 | |

| Surface Resistivity (0.030"") | 4.8 X 10^7 | MΩ | COND A | IPC-TM-650, 2.5.17.1 | |

| PIM | -166 | dBc | 50 ohm 0.060” |

43dBm 1900MHz |

|

| Electrical Strength (0.030”) | 630 | Z | V/mil | IPC-TM-650, 2.5.6.2 | |

| Flexural Strength MD | 121 (17.5) | MPa (kpsi) |

RT | ASTM D790 | |

| CMD | 92 (13.3) | ||||

| Dimensional Stability | <0.4 | X,Y | mm/m | after etch +E2/150°C |

IPC-TM-650, 2.4.39A |

| Coefficient of Thermal Expansion |

13.9 | X | ppm/°C | -55 TO 288°C | IPC-TM-650, 2.1.24 |

| 19.0 | Y | ||||

| 25.6 | Z | ||||

| Thermal Conductivity | 0.38 | Z | W/mK° | 50°C | ASTM D5470 |

| Moisture Absorption | 0.24% | 0 | 48/50 | IPC-TM-650 2.6.2.1 ASTM D570 | |

| Tg | >280 | °C | IPC-TM-650 2.4.24 | ||

| Td | 439 | °C | ASTM D3850 | ||

| Density | 1.27 | gm/cm3 | ASTM D792 | ||

| Copper Peel Strength | 8.5 | pli | 1 oz LoPro EDC | IPC-TM-650 2.4.8 | |

| Flammability | N/A | UL94 | |||

| Lead-Free Process Compatible | YES |