Home

-

High frequency PCB

-

Rogers IsoClad 917 High-Frequency PCB: 20mil Substrate with Immersion Gold and Green Solder Mask

Home

-

High frequency PCB

-

Rogers IsoClad 917 High-Frequency PCB: 20mil Substrate with Immersion Gold and Green Solder Mask

Rogers IsoClad 917 High-Frequency PCB: 20mil Substrate with Immersion Gold and Green Solder Mask

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

Introduction

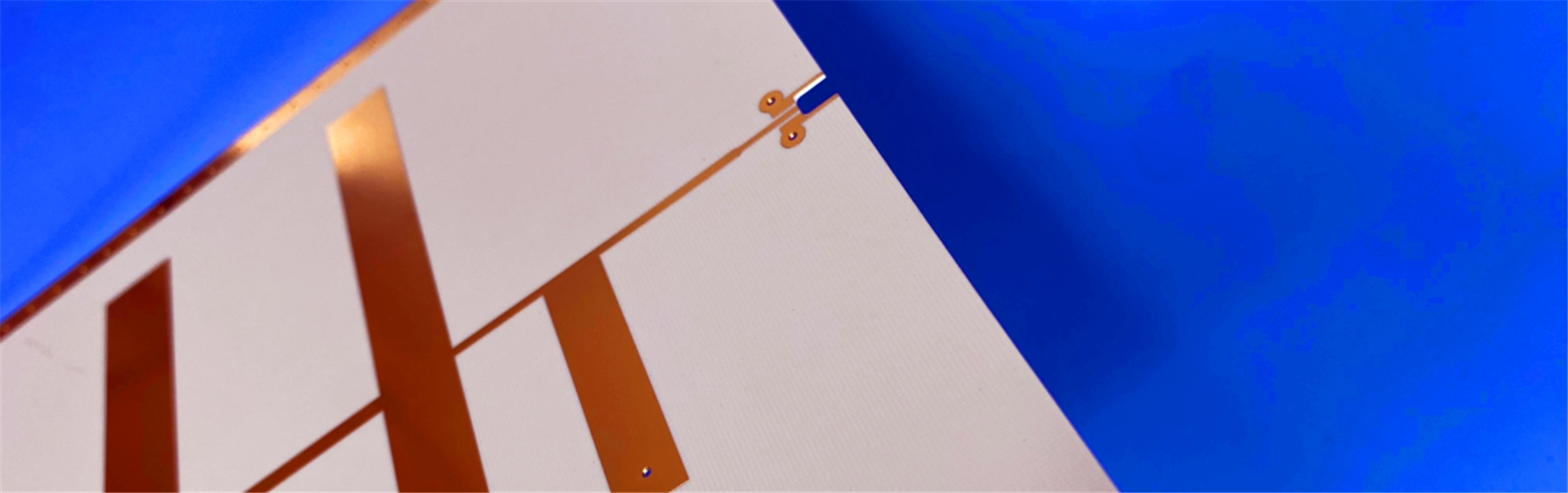

This double-sided wrap-around antenna IsoClad 917 PCB is constructed using Rogers IsoClad 917 material, featuring a 20mil (0.508mm) substrate and a copper cladding design—starting with 0.5oz copper that is plated up to 1oz (≈35μm) for enhanced conductivity.

With dimensions of 126mm in length and 95mm in width, the PCB is specifically engineered for integration into intelligent helmets. Its surface finish uses chemical gold (immersion gold) on pads and exposed tracks, ensuring excellent solderability for surface-mount device (SMD) assembly—critical for reliable component bonding in antenna applications.

The entire board is protected by a green solder mask, which shields the circuitry from environmental damage, oxidation, and mechanical wear while maintaining visual clarity for inspection. Manufactured strictly in compliance with IPC-Class 2 standards (a widely recognized benchmark for electronic assembly quality), each PCB undergoes 100% electrical testing to verify functionality and eliminate defects. For shipping, every 30 PCBs are vacuum-sealed to preserve cleanliness, prevent moisture intrusion, and ensure they arrive in optimal condition.

.jpg)

PCB Specifications

Our Advantages

- More than 19+ years of high frequency PCB experience;

- ISO9001, ISO14001, ISO13485, UL certified manufacturing factory;

- Rate of qualified products of first production: >99%

- 16000㎡ workshop; 30000㎡ output capability per month; 8000 types of PCB's per month;

- Delivery on time: >98% ; Customer complaint rate: <1%

- No MOQ, low cost for prototypes and small runs quantity;

- Prototype PCB capability to Volume Production capability;

- Wide ranges of high frequency material being chosen, Rogers, Taconic, Wangling, Shengyi etc.

- Professional and experienced engineers check your production files and strong after-sales service.

- IPC Class 2 / IPC Class 3

PCB Specifications

| PCB SIZE | 126mm x 95mm=1 piece |

| BOARD TYPE | High Frequency PCB |

| Number of Layers | 2 layers |

| Surface Mount Components | YES |

| Through Hole Components | N/A |

| LAYER STACKUP | copper ------- 17um(0.5 oz)+plate top layer |

| IsoClad 917 0.508mm | |

| copper ------- 17um(0.5 oz)+plate bot layer | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 4 mil / 4 mil |

| Minimum / Maximum Holes: | 0.2 mm / 1.2 mm |

| Number of Different Holes: | 8 |

| Number of Drill Holes: | 251 |

| Number of Milled Slots: | 3 |

| Number of Internal Cutouts: | 3 |

| Impedance Control: | no |

| Number of Gold finger: | 0 |

| BOARD MATERIAL | |

| Glass Epoxy: | IsoClad 917 0.508mm |

| Final foil external: | 1.0 oz |

| Final foil internal: | 1.0 oz |

| Final height of PCB: | 0.6 mm ±0.1 |

| PLATING AND COATING | |

| Surface Finish | Immersion Gold, 31.6% |

| Solder Mask Apply To: | Both sides |

| Solder Mask Color: | Green |

| Solder Mask Type: | Glossy |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | Top side |

| Colour of Component Legend | White |

| Manufacturer Name or Logo: | Kuangshung |

| VIA | Plated through hole(PTH), minimum size 0.2mm. via filled and tented. |

| FLAMIBILITY RATING | 94V-0 |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059"" |

| Board plating: | 0.0029"" |

| Drill tolerance: | 0.002"" |

| TEST | 100% Electrical Test prior shipment |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

FAQ's

-

Do We Deliver Worldwide?

All PCBs purchasable through Bicheng Ltd can be dispatched worldwide to any non embargoed countries. We’ll choose the suitable shipping carriers for you among DHL, FedEx, TNT, UPS, EMS and Aramex

Is the High frequency Materials In Stock?

We keep most of the high frequency material in stock with prototype quantity,such as Rogers material with 3000 series, 4000 series, 5000 series, 6000 series etc, Taconic material with RF series, TLX series, TLY series etc, Wangling material F4B with DK2.2, DK2.65 etc. Since the high frequency material has so much variety, you can consult our sales persons before ordering.

Can I Collect My Order?

It’s completely no problem to pick up ordering of boards or collection of PCBs from our premises through your account in DHL, UPS or FedEx etc.. We’ll help to prepare the necessary export documents or files for customs declare.

How Much Will It Cost For Delivery?

We have various carriers to choose. Usually, we’ll pick one with best shipping fee for you. If your order is urgent, we can help to choose the forwarder with fast timeliness.

Am I Able To Return My PCBs?

PCBs are irreversible custom-made products, it is not allowed to return the items if there’s no quality problems.

When Will My Order Arrive?

All the PCBs are dispatched the same day if they are finished fabrication before 5pm. For Asian clients, you can get it within 2-3 days, European clients in 6-7 days and American (North and South) in 6-7 days, however the carriers do not guarantee this because of the complexity of transportation.

Will I Need To Sign For My Package?

We dispatch all orders using DHL, UPS, FedEx, TNT, Aramex or EMS, so they are fully tracked and may require a signature.

How Can I Track My Order?

Once your PCB boards are dispatched, you will receive a shipping confirmation via email by our sales that includes a tracking number. You can track this number on their official websites.

What Should I Do If My Parcel Is Damaged Or Lost?

This situation is rare in our daily business. The PCB boards are packed with bubble materials inside and with KK grade carton outside to protect your PCBs. However, If your parcel is lost or damaged, you must contact us immediately so that we can contact the carrier and arrange for replacement production. Please keep any damaged items including damaged packaging for reference.

Our PCB Capability (2022)

| Parameter | Value |

| Layer Counts | 1-32 |

| Substrate Materials | RO4350B, RO4003C, RO4730G3, RO4360G2, RO4533, RO4534, RO4535, RO4835, RO3003, RO3006, RO3010, RO3035, RO3203, RO3210; RT/Duriod 5880; RT/Duriod 5870, RT/Duriod 6002, RT/Duroid 6010, RT/duroid 6035HTC; RT/duroid 5880LZ; TMM3, TMM4, TMM6, TMM10, TMM10i, TMM13i, Kappa 438; TLF-35; RF-35TC, RF-60A, RF-60TC, RF-35A2, RF-45, RF-10, TRF-45; TLX-0, TLX-6, TLX-7, TLX-8; TLX-9, TLY-3, TLY-5, TLY-5Z; PTFE F4B (DK2.2 DK2.65 DK2.85 DK2.94, DK3.0, DK3.2, DK3.38, DK3.5, DK4.0, DK4.4, DK6.15, DK10.2); AD250C, AD255C, AD300D, AD350A, AD450, AD600, AD1000, TC350; TC600; DiClad 880, DiClad 870, DiClad 527; IsoClad 917; Nelco N4000, N9350, N9240; SCGA-500 GF220, SCGA-500 GF255, SCGA-500 GF265, SCGA-500 GF300; FR-4 ( High Tg S1000-2M, TU-872 SLK, TU-768, IT-180A etc.), FR-4 High CTI>600V; Polyimide, PET; Metal Core etc. |

| Maximum Size | Flying test: 900*600mm, Fixture test 460*380mm, No test 1100*600mm |

| Board Outline Tolerance | ±0.0059"" (0.15mm) |

| PCB Thickness | 0.0157"" - 0.3937"" (0.40mm--10.00mm) |

| Thickness Tolerance(T≥0.8mm) | ±8% |

| Thickness Tolerance(t<0.8mm) | ±10% |

| Insulation Layer Thickness | 0.00295"" - 0.1969"" (0.075mm--5.00mm) |

| Minimum Track | 0.003"" (0.075mm) |

| Minimum Space | 0.003"" (0.075mm) |

| Outer Copper Thickness | 35µm--350µm (1oz-10oz) |

| Inner Copper Thickness | 17µm--350µm (0.5oz - 10oz) |

| Drill Hole(Mechanical) | 0.0079"" - 0.25"" (0.2mm--6.35mm) |

| Finished Hole(Mechanical) | 0.0039""-0.248"" (0.10mm--6.30mm) |

| DiameterTolerance(Mechanical) | 0.00295"" (0.075mm) |

| Registration (Mechanical) | 0.00197"" (0.05mm) |

| Aspect Ratio | 12:1 |

| Solder Mask Type | LPI |

| Min Soldermask Bridge | 0.00315"" (0.08mm) |

| Min Soldermask Clearance | 0.00197"" (0.05mm) |

| Plug via Diameter | 0.0098"" - 0.0236"" (0.25mm--0.60mm) |

| Impedance Control Tolerance | ±10% |

| Surface Finish | HASL,HASL LF,ENIG,Immersion Tin,Immersion Silver, OSP, Gold Finger, Pure gold plated etc. |