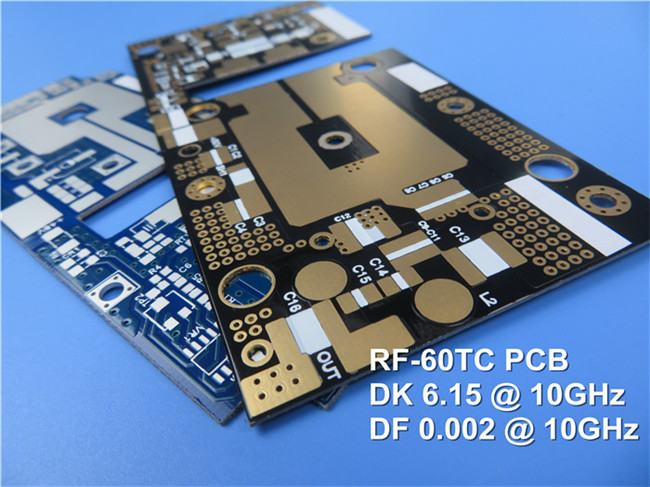

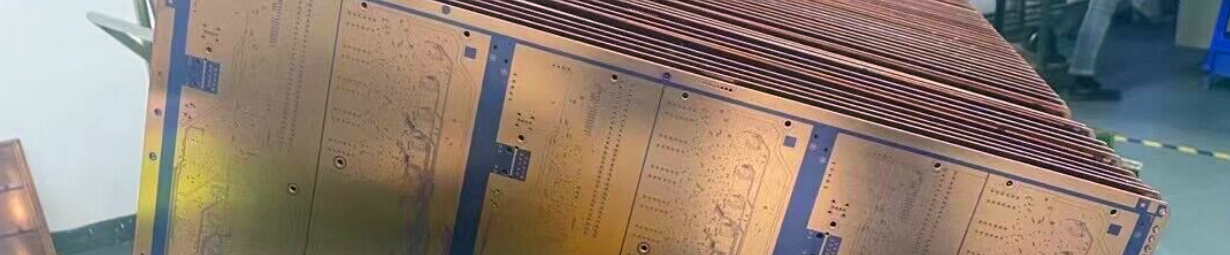

Taconic RF-60TC High Frequency PCB Material Introduction Hello everyone. Welcome back to our channel. I am Ivy, the regional sales manager for Bicheng PCB. I am happy to be the host for this episode. Today we are going introduce a type of improved heat dissipation and exceptional low loss PCB ---Taconic RF-60TC high frequency PCB. Taconic RF-60TC PCB is composed of a PTFE-based, ceramic-filled fiberglass substrate.High power RF and microwave applications can use RF-60TC laminate as their basic material. Through enhanced dielectric heat dissipation and extraordinarily low dielectric losses, this material is intended to deliver lower operating temperatures in high power applications and greater gains and efficiencies in miniaturized antenna applications for the 6.15 DK market. Now let’s see the detailed properties. RF-60TC Typical Properties The Dk, or dielectric constant, of RF-60TC at 10 GHz is 6.15 ± 0.15, while the Df, or dielectric loss tangent, is 0.002. Dielectric breakdown is 55 kV, while the dielectric strength is 550 V/mil. The arc resistance lasts longer than 180 seconds, and the surface resistivity and volume resistivity are both 1.0 x 10^8 Mohm after humidity exposure. Moving on to the mechanical properties, the flexural strength in the machine direction is 10,000 psi, while the flexural strength in the cross direction is 9,000 psi. The tensile strength in the MD is 9,000 psi, while the tensile strength in the CD is 7,000 psi. The Young's modulus in the MD is 721 kpsi, and the Poisson's ratio in the MD is 0.155. The dimensional stability in the MD after bake is 0.01 mils/in, while the dimensional stability in the CD after bake is 0.69 mils/in. The dimensional stability in the MD after thermal stress is 0.06 mils/in, while the dimensional stability in the CD after thermal stress is 0.8 mils/in. Moving on to the thermal properties, the thermal conductivity for this material is 0.9 W/MK for unclad, 1 W/MK for half ounces, and 1.05 W/MK for 1oz copper. The TCDk value of RF-60TC is -3.581 ppm/°C, while the CTE for the X and Y axis is 9.9 ppm/°C and the CTE for the Z axis is 40 ppm/°C. Finally, the physical properties of RF-60TC include a moisture absorption of 0.03%, a peel strength of 8 lbs/in for 1 oz. ED copper, a density of 2.84 g/cm3, a specific heat of 0.94 J/gK, a Td of 500°C for 2% weight loss, a Td of 515°C for 5% weight loss, and a flammability rating of V-0 according to UL 94. Property Unit RF-60TC Value Test Method Electrical Properties Dk @ 10 GHz 6.15 ± 0.15 IPC-650 2.5.5.5.1 (Modified) Df @ 10 GHz 0.002 IPC-650 2.5.5.5.1 (Modified) Dielectric Breakdown kV 55 IPC-650 2.5.6 Dielectric Strength V/mil (V/mm) 550 (21,654) IPC-650 2.5.6.2 Arc Resistance Seconds >180 IPC-650 2.5.1 Surface Resistivity Mohm 1.0 x 108 IPC-650 2.5.17.1 (After Humidity) Volume Resistivity Mohm/cm 1.0 x 108 IPC-650 2.5.17.1 (After Humidity) Mechanical Properties Flexural Strength (MD) psi (N/mm2) 10000 (69) IPC-650 2.4.4 Flexural Strength (CD) psi (N/mm2) 9000 (62) IPC-650 2.4.4 Tensile Strength (MD) psi (N/mm2) 9000 (62) IPC-650 2.4.19 Tensile Strength (CD) psi (N/mm2) 7000 (48) IPC-650 2.4.19 Young’s Modulus (MD) kpsi (N/mm2) 721 (4971) ASTM D 3039/IPC-TM-650 2.4.19 Poisson’s Ratio (MD) 0.155 ASTM D 3039/IPC-TM-650 2.4.19 Dimensional Stability (MD) mils/in 0.01 IPC-650 2.4.39 Sec. 5.4 (After Bake) Dimensional Stability (CD) mils/in 0.69 IPC-650 2.4.39 Sec. 5.4 (After Bake) Dimensional Stability (MD) mils/in 0.06 IPC-650 2.4.39 Sec. 5.5 (Thermal Stress) Dimensional Stability (CD) mils/in 0.8 IPC-650 2.4.39 Sec. 5.5 (Thermal Stress) Thermal Properties Thermal Conductivity (Unclad) W/M*K 0.9 IPC-650 2.4.50 Thermal Conductivity (CH/CH) W/M*K 1 IPC-650 2.4.50 Thermal Conductivity (C1/C1) W/M*K 1.05 IPC-650 2.4.50 TCDk ppm/°C -3.581 CTE (X, Y axis) ppm/°C 9.9 IPC-650 2.4.41 (RT- 150 °C) CTE (Z axis) ppm/°C 40 IPC-650 2.4.41 (RT- 150 °C) Physical Properties Moisture Absorption % 0.03 IPC-650 2.6.2.1 Peel Strength (1 oz. ED) lbs/in (N/mm) 8 (1.43) IPC-650 2.4.8 Density (Specific Gravity) g/cm3 2.84 IPC-650 2.3.5 Specific Heat J/gK 0.94 IPC-650 2.4.50 Td (2% Wt. Loss) °C (°F) 500 (930) IPC - 650 2.4.24.6 / TGA Td (5% Wt. Loss) °C (°F) 515 (960) IPC - 650 2.4.24.6 / TGA Flammability Rating V-0 UL 94 PCB capability (RF-60TC) Our PCBs are available in comprehensive range, including single layer, double layer, multi-layer, and hybrid PCBs. RF-60TC has a wide range of thicknesses. Thinnest at 5 mils, then followed by increments of 5 mils of 10 mils, 20 mils, 25 mils, 30 mils and 60 mils and so on. Finished copper on track lines can be 1oz and 2oz. The maximum PCB size is 400mm X 500mm with a single board or multiple designs in the panel. Various solder mask colors such as Green, Black, Blue, Red, and Yellow are offered in-house. Lastly, several surface finish options are available to choose from, including HASL, Immersion gold, Immersion silver, Immersion tin, OSP, ENEPIG, Pure gold, and Bare copper, to meet various PCB needs. PCB material: PTFE based, ceramic filled fiberglass Designation: RF-60TC Dielectric constant: 6.15 Layer count: Single layer, Double layer, Multi-layer, Hybrid PCB PCB thickness: 5mil (0.127mm); 10mil (0.254mm); 20mil (0.508mm), 25mil(0.635mm); 30mil (0.762mm), ?60mil (1.524mm) Copper weight: 1oz (35µm), 2oz (70µm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Red, Yellow etc. Surface finish: HASL, Immersion gold, Immersion silver, Immersion tin, OSP, ENEPIG, Pure gold and Bare copper etc.. A Piece of RF-60TC PCB On the screen is a type of double sided RF-60TC PCB built on 25mil substrates with immersion gold on pads for the application of dividers. Taconic RF-60TC PCBs are also utilized in more fields like High Power Amplifiers, Miniaturized Antennas, GPS, Patch, RFID reader, Filters, Couplers and Satellites etc Conclusion Taconic RF-60TC PCB is a collection of mechanically supported, high thermal conductivity laminates that give 3 to 5 times the thermal conductivity of FR-4 based alternatives. OK. This concludes the episode. Thank you for reading. See you next time.