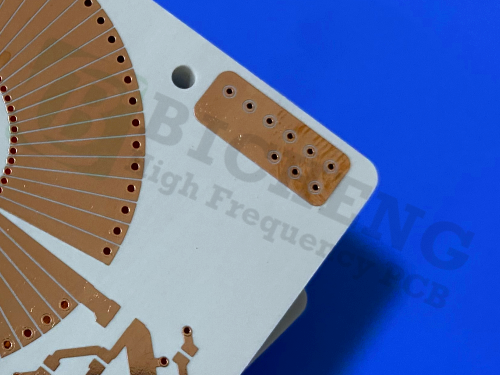

TFA series High Frequency PCB Material Introduction The dielectric layer of the Polytetrafluoroethylene ceramic composite dielectric substrate TFA series consists of PTFE resin and ceramics, and is not produced using the traditional method of impregnating glass fiber cloth with resin to make prefabricated sheets. Instead, a new process is employed to create prefabricated sheets, which are then pressed using a special lamination process. This material exhibits outstanding electrical, thermal, and mechanical properties with excellent dielectric constant at the same level, making it an aerospace-grade high-frequency and high-reliability material that can replace similar foreign products. This series of substrates does not contain glass fiber cloth. It utilizes a large amount of uniform special nano-ceramics mixed with resin, eliminating the fiberglass effect during the propagation of electromagnetic waves. It offers excellent frequency stability, with minimal dielectric loss at the same level. The material's X/Y/Z anisotropy is minimized, and it also features a low thermal expansion coefficient equivalent to copper foil and stable dielectric temperature characteristics. The dielectric constant of this series includes four options: 2.94, 3.0, 6.15, and 10.2 for selection. The corresponding part numbers are TFA294, TFA300, TFA615, TFA1020. The TFA series comes standard with RTF low roughness copper foil, reducing conductor loss while providing excellent peel strength. It can also be paired with rolled copper foil, and the TFA series can be matched with copper-based or aluminum-based materials. TFA294 and TFA300 can be paired with buried 50Ω resistance copper foil to form a resistance film laminate. The circuit boards can be processed using standard PTFE board processing technology, exhibiting excellent mechanical and physical properties suitable for multi-layer, high-layer, and backplane processing. They also demonstrate excellent processability in dense hole and fine line processing. Features 1.Small dielectric constant tolerance, excellent batch-to-batch consistency. 2.Lowest dielectric loss at the same level. 3.Operating frequency up to 77 GHz, suitable for millimeter-wave and automotive radar applications. 4.Maintains excellent frequency stability and phase stability between -55°C and 150°C. 5.Excellent radiation resistance; even after irradiation treatment, it retains stable dielectric and physical properties. 6.Low outgassing performance; meets the vacuum outgassing requirements for aerospace applications according to standard methods for testing material volatilization under vacuum conditions. 7.Outstanding thermal expansion coefficient equivalent to copper foil; ensures the reliability of plated-through holes and dimensional thermal stability. 8.Low water absorption; ensures material stability in humid environments. Typical Applications Aerospace and aviation equipment, space and cabin equipment, aircraft Microwave, antennas, phase-sensitive antennas Warning radar, airborne radar, and various radar systems Phased array antennas, beamforming networks Satellite communication, navigation Power amplifiers Data Sheet Product Technical Parameter Typical Value Properties Test conditions Unit TFA294 TFA300 TFA615 TFA1020 Dielectric constant 10GHz / 2.94 3.00 6.15 10.20 Dielectric constant 10GHz / 2.94 3.00 6.4 10.7 Dielectric / / ±0.04 ±0.04 ±0.12 ±0.20 Loss factor 10GHz / 0.001 0.001 0.0015 0.0015 20GHz / 0.001 0.001 0.0017 0.0017 40GHz / 0.0012 0.0012 / / Dielectric constant -55 º~150ºC PPM/℃ -5 -8 -215 -340 Peel strength 1 OZ RTF N/mm >1.6 >1.6 >1.6 >1.6 Volumetric Normal MΩ.cm ≥5×107 ≥5×107 ≥5×107 ≥5×107 Surface resistance Normal MΩ ≥5×107 ≥5×107 ≥5×107 ≥5×107 Electrical strength 5KW,500V/s KV/mm >35 >32 >30 >30 Breakdown voltage 5KW,500V/s KV >40 >40 >30 >25 Thermal expansion -55 º~288ºC ppm/ºC 18, 18 18, 18 16, 16 16, 16 Thermal expansion -55 º~288ºC ppm/ºC 32 30 29 30 Thermal stress 260℃, 10s,3 - Not stratified Not stratified Not stratified Not stratified Water absorption 20±2℃, 24h % 0.03 0.04 0.06 0.015 Density Normal g/cm3 2.14 2.15 2.5 3.0 Long-term High and low ℃ -55~+260 -55~+260 -55~+260 -55~+260 Thermal Z-direction W/(M.K) 0.59 0.60 0.80 0.88 Flame retardancy / UL-94 V-0 V-0 V-0 V-0 TD Starting value ℃ 498 498 503 505 Material / / PTFE,ceramics

(typical value)

(design value)

constant tolerance

(typical value)

temperature coefficient

copper foil

resistivity

(Z-direction)

(XY direction)

coefficient(X,Y direction)

coefficient (Z-direction)

times

temperature

use temperature

temperature box

conductivity

composition

(a very small amount of glass fiber cloth is added

when the dielectric thickness exceeds 1.5 mm)