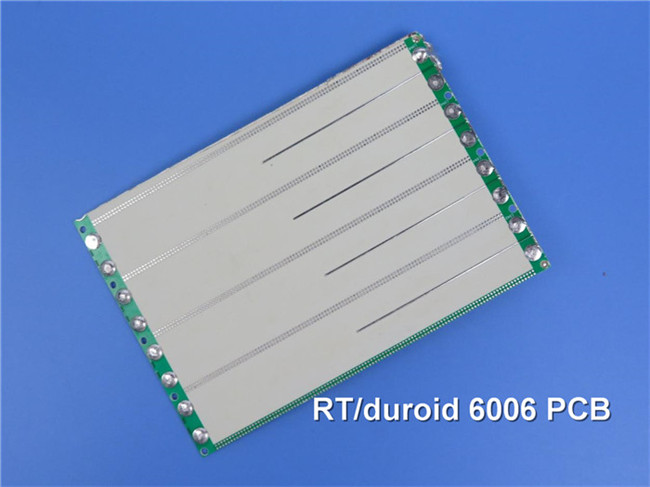

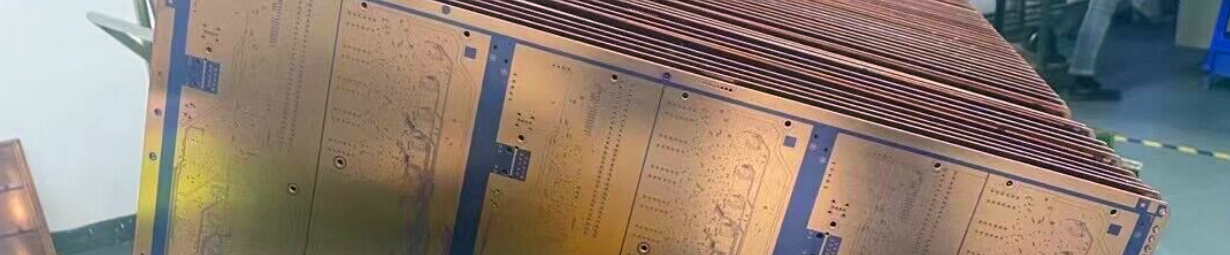

Rogers RT/duroid 6006 High Frequency PCB Material Introduction Hello everyone. Welcome back to our channel. Today, we’re going to talk about Rogers’ RT/duroid 6006 high frequency PCB. Rogers RT/duroid 6006 PCBs are ceramic-PTFE composites which are designed for electronic and microwave circuit applications requiring a high dielectric constant. RT/duroid 6006 PCB can provide us with high dielectric constant which is helpful to enable circuit size reduction. With low loss property, it is ideal for operating at X-band or below. Additionally, the tight Dk and thickness control deliver repeatable circuit performance. RT/duroid 6006 Typical Properties Let's delve into the technical specifications and characteristics outlined in the data sheet. Starting with the dielectric properties, the RT/duroid 6006 exhibits a process dielectric constant, εProcess, of 6.15±0.15 at 10 GHz and 23℃. This ensures excellent signal performance and stability. Additionally, the design dielectric constant, εDesign, measures at 6.45, covering a frequency range of 8 GHz to 40 GHz using the Differential Phase Length Method. The high dielectric constant (DK value) allows for greater space in PCB circuit design, making miniaturization of products possible. Moving on to dissipation factor, or tanδ, the RT/duroid 6006 showcases a low value of 0.0027 at 10 GHz, guaranteeing minimal signal loss and high signal integrity. Now let's discuss the material's thermal coefficient of dielectric constant, which is -410 ppm/℃ in the temperature range of -50℃ to 170℃. This indicates the RT/duroid 6006 has variant dielectric properties across a wide temperature spectrum. That is to say RT/duroid 6006 is not suitable for millimeter wave area and the environments that temperature changes a lot. In terms of electrical properties, the volume resistivity is measured at 7 x 10^7 Mohm.cm, showcasing excellent electrical insulation capabilities. Similarly, the surface resistivity is 2 x 10^7 Mohm, further highlighting the material's strong electrical performance. Moving on to the mechanical properties, the RT/duroid 6006 exhibits impressive tensile properties. In the X-axis, the Young's modulus measures 627 MPa (91 kpsi), while in the Y-axis, it measures 517 MPa (75 kpsi). The ultimate stress is 20 MPa (2.8 kpsi) in the X-axis and 17 MPa (2.5 kpsi) in the Y-axis. Furthermore, the ultimate strain ranges from 12% to 13% in the X-axis and from 4% to 6% in the Y-axis. Switching to compressive properties, the RT/duroid 6006 demonstrates a Young's modulus of 1069 MPa (115 kpsi) in the Z-axis, along with an ultimate stress of 54 MPa (7.9 kpsi). The ultimate strain in the Z-axis measures at 33%. Next, let's focus on the material's flexural modulus, which is 2634 MPa (382 kpsi) in the X-axis and 1951 MPa (283 kpsi) in the Y-axis. The ultimate stress in the X-axis is 38 MPa (5.5 kpsi). Under load, the RT/duroid 6006 exhibits a deformation rate of 0.33% in the Z-axis after 24 hours at 50℃ and 7 MPa. Similarly, at 150℃ and 7 MPa, the deformation rate is 2.1% in the Z-axis, showcasing the material's dimensional stability under pressure and heat. The moisture absorption of the RT/duroid 6006 is an impressively low 0.05%, as determined by D48/50℃ testing with a thickness of 0.050" (1.27mm), ensuring its reliability and stability in humid environments. Moisture absorption is the total weight of the circuit board material absorbing external water, which is measured in percentage. At higher frequencies the smaller the better, with a typical value of between 0.1% and 0.2%. The water absorption of RT/duroid 6006 performs as low as 0.05%. Regarding thermal conductivity, the material exhibits a value of 0.49 W/m/k at 80℃, indicating good heat dissipation capabilities. The coefficient of thermal expansion for the RT/duroid 6006 is 47 ppm/℃ in the X-axis, 34 ppm/℃ in the Y-axis, and 117 ppm/℃ in the Z-axis at 23℃ and 50% RH, reflecting its ability to withstand temperature changes without significant dimensional variations. RT/duroid 6006 material's thermal decomposition temperature (Td) is 500℃, as determined by TGA testing, ensuring its stability in high-temperature environments. With a density of 2.7 g/cm3, the RT/duroid 6006 strikes a balance between lightweight design and robust performance. In terms of specific heat, it measures 0.97 j/g/k (0.231 BTU/ib/OF), providing insights into its heat absorption and retention capabilities. Rogers RT/duroid 6006 boasts a copper peel strength of 14.3 pli (2.5 N/mm) after undergoing solder float, ensuring secure adhesion and reliability in demanding applications. It is important to note that the material has achieved a V-0 rating for flammability based on UL 94 testing. Rogers RT/duroid 6006 PCB is fully compatible with lead-free processes, making it an ideal choice for modern, environmentally conscious manufacturing. Property RT/duroid 6006 Direction Units Condition Test Method Dielectric Constant,εProcess 6.15±0.15 Z 10 GHz/23℃ IPC-TM-650 2.5.5.5 Clamped stripline Dielectric Constant,εDesign 6.45 Z 8GHz to 40 GHz Differential Phase Length Method Dissipation Factor,tanδ 0.0027 Z 10 GHz/A IPC-TM-650 2.5.5.5 Thermal Coefficient of ε -410 Z ppm/℃ -50℃-170℃ IPC-TM-650 2.5.5.5 Volume Resistivity 7 x 107 Mohm.cm A IPC 2.5.17.1 Surface Resistivity 2 x 107 Mohm A IPC 2.5.17.1 Tensile Properties ASTM D638 (0.1/min. strain rate) Young's Modulus 627(91) 517(75) X Y MPa(kpsi) A Ultimate Stress 20(2.8) 17(2.5) X Y MPa(kpsi) A Ultimate Strain 12 to 13 4 to 6 X Y % A Compressive Properties ASTM D695 (0.05/min. strain rate) Young's Modulus 1069 (115) Z MPa(kpsi) A Ultimate Stress 54(7.9) Z MPa(kpsi) A Ultimate Strain 33 Z % Flexural Modulus 2634 (382) 1951 (283) X MPa(kpsi) A ASTM D790 Ultimate Stress 38 (5.5) X Y MPa(kpsi) A Deformation under load 0.33 2.1 Z Z % 24hr/50℃/7MPa ??24hr/150℃/7MPa ASTM D261 Moisture Absorption 0.05 % D48/50℃ 0.050"(1.27mm) thick IPC-TM-650 2.6.2.1 Thermal Conductivity 0.49 W/m/k 80℃ ASTM C518 Coefficient of Thermal Expansion 47 X ppm/℃ 23℃/50% RH IPC-TM-650 2.4.41 Td 500 ℃?TGA ASTM D3850 Density 2.7 g/cm3 ASTM D792 Specific Heat 0.97(0.231) j/g/k Calculated Copper Peel 14.3 (2.5) pli (N/mm) after solder float IPC-TM-650 2.4.8 Flammability V-0 UL 94 Lead-free Process Compatible Yes PCB Capability(RT/duroid 6006) For RT/duroid 6006 PCBs, we can provide you with single layer board, double layer board, multi-layer board and hybrid types. Rogers RT/duroid 6006 PCBs have wide thickness. These are the standard thickness such as 10 mils, 25 mils, 50 mils and 75mils etc. Finished copper on PCB is 1oz and 2oz. Our maximum PCB size on RT/duroid 6006 laminate is 400mm by 500mm, it can be a single board in the sheet and also can be different designs in this panel. Solder mask of green, black, blue and yellow etc is available in house. There’s immersion gold, HASL, immersion silver, immersion tin, bare copper and OSP etc. for pads protection. PCB material: Ceramic-PTFE Composites Designation: RT/duroid 6006 Dielectric constant: 6.15 Dissipation factor 0.0027 10GHz Layer count: Single-sided PCB, Double-sided PCB, Multi-layer PCB, Hybrid types Dielectric thickness: 10mil(0.254mm), 25mil (0.635mm), 50mil (1.27mm), 75mil (1.905mm), 100mil(2.54mm) Copper weight: 1oz (35µm), 2oz (70µm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Yellow, Red etc. Surface finish: Immersion gold, HASL, Immersion silver, Immersion tin, Bare copper, OSP, ENEPIG, Pure gold etc.. A Piece of Rogers RT/duroid 6006 PCB Now on the screen is a type of 50mil RT/duroid 6006 PCB with immersion silver for patch antennas. Rogers RT/duroid 6006 PCBs can be used in applications of 8 to 40 GHz of telecommunications, aerospace and defence etc. We can also see their applications in aircraft collision avoidance systems, ground radar warning systems and satellite communications systems etc. Conclusion That concludes our overview of the remarkable properties and characteristics of Rogers RT/duroid 6006 and our printed circuit boards on it. If you have any further questions or would like more information, please feel free to ask. Thank you for your attention. OK. This concludes today’s episode. Thank you for reading. See you next time.

34

117

Y

Z

(BTU/ib/OF)