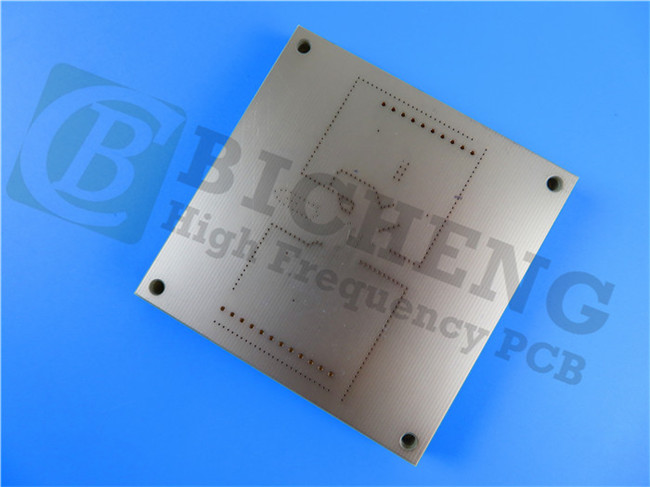

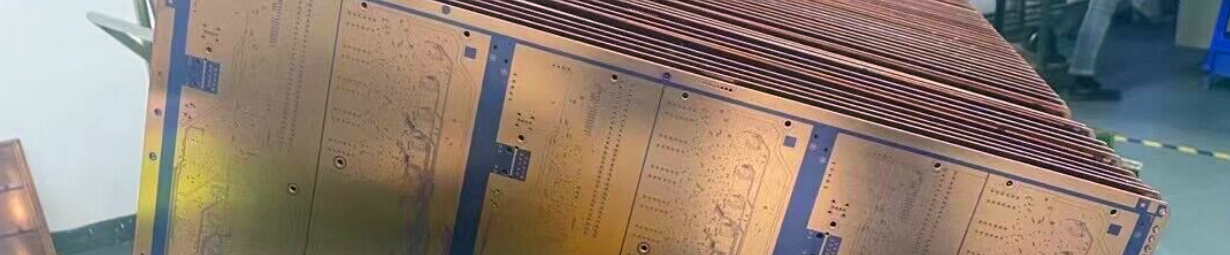

Rogers RO3006 High Frequency PCB Material Introduction Hello everyone. Welcome back to our channel. Today we’re talking about Rogers high frequency PCB built on 3006 laminate. Rogers RO3006 PCBs are ceramic-filled PTFE composites designed to offer exceptional electrical and mechanical stability at competitive price, intended for use in commercial microwave and RF applications. RO3006 Typical Properties RO3000 high frequency circuit material is known for its exceptional properties, and we'll explore some of its key features. Starting with the dielectric constant, in the manufacturing process, RO3006 laminate typically exhibits a value of 6.15±0.05 at 10 GHz and 23℃ (IPC-TM-650 2.5.5.5 Clamped Stripline). For design purposes, the dielectric constant is estimated to be 6.5 within the frequency range of 8 GHz to 40 GHz, as determined by the Differential Phase Length Method. The high dielectric constant enable designers to design the circuit board smaller. So we can miniaturize our circuit size using RO3006. The DK is stable over a wide range of temperatures, so this eliminates the step change in Dk that occurs for PTFE glass materials near room temperature. Next, let's discuss the dissipation factor, or tan delta, which is an important parameter for loss characterization. Rogers 3006 substrate demonstrates a low dissipation factor of 0.002 at 10 GHz and 23℃ (IPC-TM-650 2.5.5.5). This attribute contributes to its excellent signal integrity and low signal loss which helps power amplifier for high gain. When it comes to thermal properties, Rogers RO3006 circuit material exhibits a thermal coefficient of dielectric constant of -262 ppm/℃ within the temperature range of -50℃ to 150℃ at 10 GHz (IPC-TM-650 2.5.5.5). This indicates its ability to maintain stable electrical performance across a wide temperature range. Moving on to dimensional stability, Rogers 3006 substrate showcases outstanding stability with a dimensional change of 0.27 mm/m in the X direction and 0.15 mm/m in the Y direction under specified conditions (COND A, IPC-TM-650 2.2.4). This ensures reliability and precision in various applications. RO3006 also possesses excellent electrical properties. Rogers 3006 laminate exhibits a volume resistivity of 10^5 MΩ.cm and a surface resistivity of 10^5 MΩ under specified conditions (COND A, IPC 2.5.17.1). These characteristics contribute to its suitability for high-frequency applications that require reliable insulation. Furthermore, the material's mechanical properties are noteworthy. Rogers 3006 circuit board demonstrates a tensile modulus of 1498 MPa in the X direction and 1293 MPa in the Y direction at 23℃ (ASTM D 638). This high modulus ensures structural integrity and durability. In terms of moisture absorption, RO3006 laminate has a low moisture absorption rate of 0.02% (D48/50, IPC-TM-650 2.6.2.1). This attribute is crucial for maintaining stable electrical performance in humid environments. Other important properties include a specific heat of 0.86 j/g/k (calculated), indicating its ability to dissipate heat efficiently, and a thermal conductivity of 0.79 W/M/K at 50℃ (ASTM D 5470), contributing to effective thermal management, and that does really help thermal management issue for power amplifiers. When considering its response to temperature variations, RO3006 exhibits a coefficient of thermal expansion of 17 ppm/℃ in the X and Y directions and 24 ppm/℃ in the Z direction (-55 to 288℃, 23℃/50% RH, IPC-TM-650 2.4.4.1). This allows for more reliable surface mounted assemblies, it’s ideal for applications sensitive to temperature change. That’s considered pretty good for the plated through holes reliability and excellent dimensional stability. Additionally, RO3006 has a high thermal decomposition temperature (Td) of 500℃ (TGA, ASTM D 3850), indicating its ability to withstand elevated temperatures without significant degradation. In terms of material density, RO3006 has a density of 2.6 gm/cm3 at 23℃ (ASTM D 792). This characteristic contributes to its lightweight yet robust nature. Furthermore, RO3006 exhibits excellent copper peel strength, with a value of 7.1 Ib/in. This measurement is conducted on 1oz copper after solder float (IPC-TM 2.4.8), ensuring reliable adhesion between the material and copper layers. RO3006 also meets safety standards, as it achieves a flammability rating of V-0 (UL 94). Additionally, it is compatible with lead-free processes, making it environmentally friendly and compliant. Property RO3006 Direction Units Condition Test Method Dielectric Constant,εProcess 6.15±0.05 Z 10 GHz/23℃ IPC-TM-650 2.5.5.5 Clamped Stripline Dielectric Constant,εDesign 6.5 Z 8GHz to 40 GHz Differential Phase Length Method Dissipation Factor,tanδ 0.002 Z 10 GHz/23℃ IPC-TM-650 2.5.5.5 Thermal Coefficient of ε -262 Z ppm/℃ 10 GHz -50℃to 150℃ IPC-TM-650 2.5.5.5 Dimensional Stability 0.27 X mm/m COND A IPC-TM-650 2.2.4 Volume Resistivity 105 MΩ.cm COND A IPC 2.5.17.1 Surface Resistivity 105 MΩ COND A IPC 2.5.17.1 Tensile Modulus 1498 X MPa 23℃ ASTM D 638 Moisture Absorption 0.02 % D48/50 IPC-TM-650 2.6.2.1 Specific Heat 0.86 j/g/k Calculated Thermal Conductivity 0.79 W/M/K 50℃ ASTM D 5470 Coefficient of Thermal Expansion 17 X ppm/℃ 23℃/50% RH IPC-TM-650 2.4.4.1 Td 500 ℃?TGA ASTM D 3850 Density 2.6 gm/cm3 23℃ ASTM D 792 Copper Peel Stength 7.1 Ib/in. 1oz,EDC After Solder Float IPC-TM 2.4.8 Flammability V-0 UL 94 Lead-free Process Compatible Yes PCB Capability (RO3006) For RO3006 PCBs, we can provide you with single layer board, double layer board, multi-layer board and hybrid types. Rogers RO3006 PCBs have wide thickness. These are the standard thickness such as 5 mils, 10 mils, 20 mils, 25 mils and 50mils etc. Finished copper on PCB can be 1oz, 2oz and 3oz. Our maximum PCB size on high frequency materials is 400mm by 500mm, it can be a single board in the sheet and also can be different designs in this panel. Solder mask of green, black, blue, red and yellow etc is available in house. There’s immersion gold, HASL, immersion silver, immersion tin, bare copper etc. for pads surface finish. PCB material: Ceramic-filled PTFE composite Designation: RO3006 Dielectric constant: 6.15 ±0.3 (process), 6.5 (design) Layer count: 1-layer, 2-layer, Multi-layer, Hybrid PCB Dielectric thickness: 5mil (0.127mm), 10mil (0.254mm), 25mil (0.635mm), 50mil (1.27mm) Copper weight: 1oz (35µm), 2oz (70µm), 3oz (105 µm) PCB size: ≤400mm X 500mm Solder mask: Green, Black, Blue, Red, Yellow etc. Surface finish: Immersion gold, HASL, Immersion silver, Immersion tin, ENEPIG, Bare copper, OSP, Pure thick gold etc.. A Piece of RO3006 PCB On the screen is a type of 50mil RO3006 PCB with immersion gold. We can see its typical applications in GPS antennas, power amplifiers and antennas, patch antennas for wireless communications and direct broadcast satellite etc. Conclusion To summarize, Rogers RO3006 is a high-performance laminate material with a dielectric constant of 6.15±0.05 in the manufacturing process and 6.5 for design purposes. Rogers RO3006 PCB exhibits low dissipation factor, excellent thermal stability, dimensional accuracy, superior electrical properties, reliable mechanical performance, high Td, good density, and strong copper peel strength. Furthermore, Rogers RO3006 high-frequency laminate PCB possesses low moisture absorption, good thermal conductivity, and meets safety standards. Rogers 3006 PCB manufacturing process is similar to standard PTFE PCB, so we can get volume manufacturing process and economical pricing to win the market. That concludes our overview of Rogers RO3006 material and PCBs. Thank you for joining us today, and we hope you found this information valuable. If you have any further questions, please feel free to ask.

0.15

Y

1293

Y

(-55 to 288℃)

17

24

Y

Z