Home

-

Heavy Copper PCB

-

Rogers RO3003 Ceramic-Filled PTFE PCB 4-Layer 1.6mm RF Board for ADAS and Wireless Infrastructure

Home

-

Heavy Copper PCB

-

Rogers RO3003 Ceramic-Filled PTFE PCB 4-Layer 1.6mm RF Board for ADAS and Wireless Infrastructure

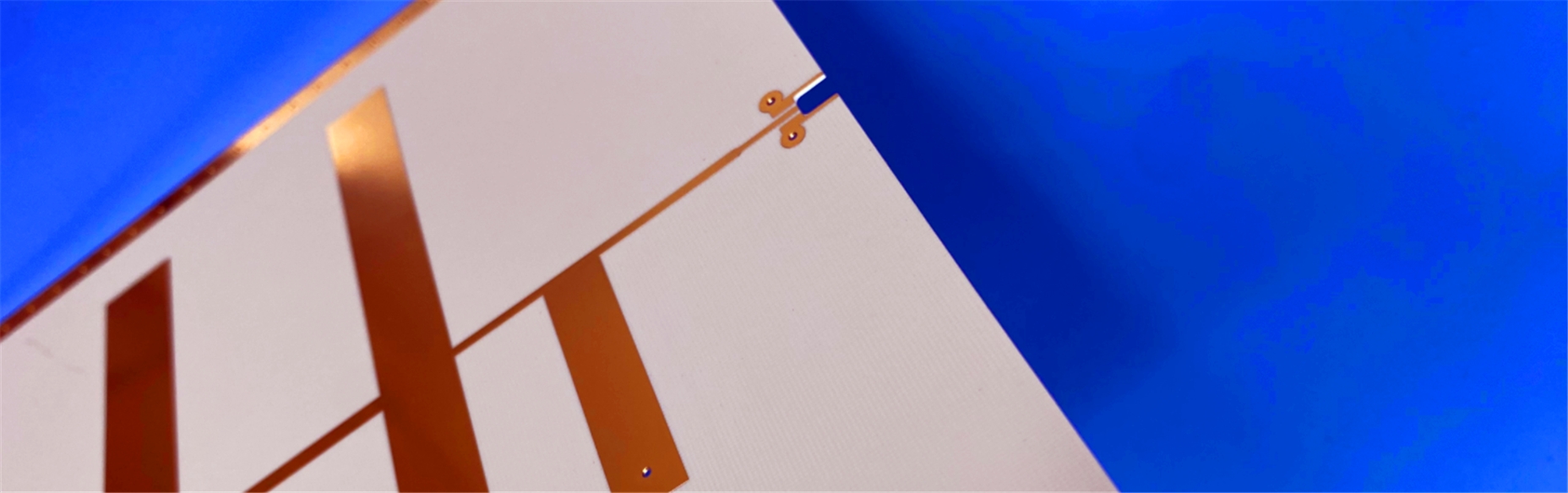

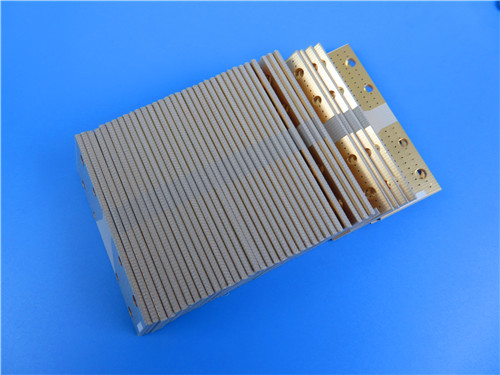

Rogers RO3003 Ceramic-Filled PTFE PCB 4-Layer 1.6mm RF Board for ADAS and Wireless Infrastructure

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

General Description

This 4-layer rigid PCB is constructed using Rogers RO3003 ceramic-filled PTFE composite material, designed for demanding high-frequency applications in the automotive, telecommunications, and satellite communications sectors. With a compact board size of 110.9mm × 110.9mm and a finished thickness of 1.64mm, this PCB incorporates advanced blind and buried via technology (L1-L2, L2-L3) to support complex RF circuit designs. The board features immersion gold surface finish and maintains tight tolerances with 4/5 mils minimum trace/space and 0.25mm minimum hole size, ensuring reliable performance in high-frequency environments up to 77 GHz.

PCB Construction Specifications

Parameter |

Specification |

Base Material |

RO3003 Ceramic-filled PTFE |

Layer Count |

4 Layers |

Board Dimensions |

110.9mm × 110.9mm |

Board Thickness |

1.64mm |

Minimum Trace/Space |

4/5 mils |

Minimum Hole Size |

0.25mm |

Via Types |

Blind vias (L1-L2, L2-L3) |

Copper Weight |

1oz outer layers |

Via Plating Thickness |

20μm |

Surface Finish |

Immersion Gold |

Solder Mask |

None |

Silkscreen |

None |

Electrical Test |

100% tested |

Additional Components & Features

4-Layer Rogers RO3003 PCB accommodates 37 components with 193 total pads, including 135 through-hole pads and 58 surface mount pads on the top layer. The design incorporates 79 vias and 2 nets, providing comprehensive connectivity for complex RF circuits. The stackup configuration consists of Rogers RO3003 substrates with 5mil and 50mil thicknesses, separated by 4mil prepreg layers, all clad with 35μm copper layers. This construction ensures optimal signal integrity and thermal management for high-frequency applications.

Material Advantages

RO3003 laminates deliver exceptional dielectric constant stability (3.0±0.04) across temperature variations and frequency ranges, eliminating the step change in Dk typically associated with PTFE glass materials near room temperature. The material's low dissipation factor (0.001 at 10 GHz) and thermal conductivity of 0.5 W/mK ensure minimal signal loss and effective heat dissipation. With a low moisture absorption rate of 0.04% and CTE values closely matched to copper (X:17, Y:16, Z:25 ppm/°C), these laminates provide excellent dimensional stability and reliability in multi-layer board constructions.

Typical Applications

Rogers RO3003 high-frequency PCB is ideal for automotive radar systems operating at 77 GHz, advanced driver assistance systems (ADAS), and 5G wireless infrastructure including mmWave applications. Additional applications include global positioning satellite antennas, cellular telecommunications power amplifiers and antennas, patch antennas for wireless communications, direct broadcast satellites, and various RF components such as band pass filters and voltage controlled oscillators.

Why Choose This PCB?

The combination of Rogers RO3003 material properties and advanced PCB manufacturing techniques results in a high-frequency solution that offers consistent electrical performance, excellent mechanical stability, and cost-effective production. The material's stable dielectric constant across temperature and frequency variations, combined with its compatibility with epoxy glass multi-layer board hybrid designs, makes it an optimal choice for demanding RF applications requiring precision and reliability.

Order Now for Advanced RF Applications!

This Rogers RO3003-based PCB solution is readily available for prototyping and volume production, supporting your high-frequency design requirements with guaranteed performance and reliability. Contact us today to discuss how this advanced PCB technology can enhance your automotive radar, 5G infrastructure, or satellite communication systems.