Home

-

Ceramic PCB

-

AlN Substrate Ceramic PCB 6-Layer 1.5mm Immersion Gold High-Frequency Board for Hassle-free Signal Transmission Prototypes Available

Home

-

Ceramic PCB

-

AlN Substrate Ceramic PCB 6-Layer 1.5mm Immersion Gold High-Frequency Board for Hassle-free Signal Transmission Prototypes Available

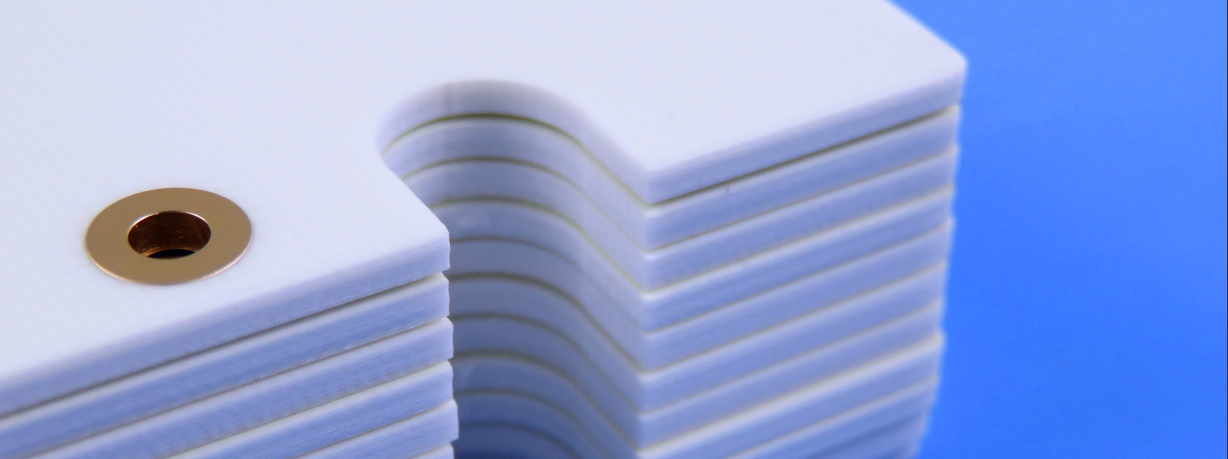

AlN Substrate Ceramic PCB 6-Layer 1.5mm Immersion Gold High-Frequency Board for Hassle-free Signal Transmission Prototypes Available

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

Brief Introduction

This ceramic circuit board features a sophisticated 6-layer design, with aluminum nitride (AlN) selected as its substrate material. AlN is renowned for its exceptional thermal conductivity and electrical insulation performance, which enables efficient heat dissipation—critical for maintaining stable operation of high-power or high-frequency components. The finished thickness of the board is 1.5mm, and both the inner and outer layers are constructed with 1oz finished copper to ensure reliable conductivity. This PCB is free of solder mask and silkscreen markings, and its surface finish adopts a 2 micro-inch (2u") immersion gold process to enhance solderability, oxidation resistance, and long-term durability. All units are manufactured in compliance with the IPC-Class-2 quality standard, guaranteeing consistent performance and reliability for various electronic applications.

Basic Specifications

Board dimensions: 51 mm x 52 mm=1PCS, +/- 0.15mm

Minimum Trace/Space: 5/5 mils

Minimum Hole Size: 0.4mm

No Blind vias.

Finished board thickness: 1.5mm +/-10%

Finished Cu weight: 1oz (1.4 mils) outer layers

Via plating thickness: 20 μm

Surface finish: Electroless Nickel Immersion Gold (ENIG)

Top Silkscreen: No

Bottom Silkscreen: No

Top Solder Mask: No

Bottom Solder Mask: No

100% Electrical test used prior to shipment

Basic Specifications

| PCB SIZE | 51 x 52mm=1PCS |

| BOARD TYPE | |

| Number of Layers | Double sided Ceramic PCB |

| Surface Mount Components | YES |

| Through Hole Components | YES |

| LAYER STACKUP | copper ------- 35um(1oz) |

| AlN Ceramic -0.39mm | |

| copper ------- 35um(1oz) | |

| ----Prepreg---- | |

| copper ------- 35um(1oz) | |

| AlN Ceramic -0.39mm | |

| copper ------- 35um(1oz) | |

| ----Prepreg---- | |

| copper ------- 35um(1oz) | |

| AlN Ceramic -0.39mm | |

| copper ------- 35um(1oz) | |

| TECHNOLOGY | |

| Minimum Trace and Space: | 5mil / 5mil |

| Minimum / Maximum Holes: | 0.4mm / 1.0mm |

| Number of Different Holes: | 8 |

| Number of Drill Holes: | 31 |

| Number of Milled Slots: | 0 |

| Number of Internal Cutouts: | 1 |

| Impedance Control | no |

| BOARD MATERIAL | |

| Glass Epoxy: | AIN Ceramic |

| Final foil external: | 1.0 oz |

| Final foil internal: | 1.0 oz |

| Final height of PCB: | 1.5 mm ±0.15mm |

| PLATING AND COATING | |

| Surface Finish | Electroless Nickel Immersion Gold (ENIG) |

| Solder Mask Apply To: | NO |

| Solder Mask Color: | NO |

| Solder Mask Type: | N/A |

| CONTOUR/CUTTING | Routing |

| MARKING | |

| Side of Component Legend | NO |

| Colour of Component Legend | NO |

| Manufacturer Name or Logo: | N/A |

| VIA | Plated Through Hole(PTH) |

| FLAMIBILITY RATING | 94 V-0 |

| DIMENSION TOLERANCE | |

| Outline dimension: | 0.0059"" (0.15mm) |

| Board plating: | 0.0030"" (0.076mm) |

| Drill tolerance: | 0.002"" (0.05mm) |

| TEST | 100% Electrical Test prior shipment |

| TYPE OF ARTWORK TO BE SUPPLIED | email file, Gerber RS-274-X, PCBDOC etc |

| SERVICE AREA | Worldwide, Globally. |

.png)

Data Sheets

| 1.Ceramic Parameters | 2. Material Thickness | ||||||||||

| Items | Unit | Al2O3 | Si3N4 | Copper Thickness | |||||||

| Density | g/cm3 | ≥3.3 | ≥3.22 | 0.15mm | 0.25mm | 0.30mm | 0.50mm | 0.8mm | |||

| Roughness (Ra) | μm | ≤0.6 | ≤0.7 | Ceramic Thickness | 0.25mm | Si3N4 | Si3N4 | Si3N4 | Si3N4 | - | |

| Bending strength | Mpa | ≥450 | ≥700 | 0.32mm | Si3N4 | Si3N4 | Si3N4 | Si3N4 | Si3N4 | ||

| Coefficient of thermal expansion | 10^-6/K | 4.6~5.2 (40-400℃) | 2.5~3.1 (40-400℃) | 0.38mm | AlN | AlN | AlN | - | - | ||

| Thermal conductivity | W/(m*K) | ≥170 (25℃) | 80 (25℃) | 0.50mm | AlN | AlN | AlN | - | - | ||

| Dielectric constant | 1MHz | 9 | 9 | 0.63mm | AlN | AlN | AlN | - | - | ||

| Dielectric loss | 1MHz | 2*10^-4 | 2*10^-4 | 1.00mm | AlN | AlN | AlN | - | - | ||

| Volume resistivity | Ω*cm | >10^14 (25℃) | >10^14 (25℃) | ||||||||

| Dielectric strength | kV/mm | >20 | >15 |

Introduction to AlN Ceramic Substrates

Aluminum Nitride (AlN) Ceramic Copper Clad Laminate—commonly referred to as AlN copper clad laminate—is a specialized electronic material. It consists of an aluminum nitride (AlN) ceramic substrate with a high-purity copper layer bonded to its surface. This material integrates three key advantages: the ultra-high thermal conductivity of AlN ceramic, excellent electrical insulation, and the superior electrical conductivity of metallic copper. As a result, it has become a core material in fields such as high-power electronic devices, high-frequency communications, and new energy vehicles, and is widely recognized as the "ultimate solution to heat dissipation challenges in the electronics industry."

Features & Benefits

1. Ultra-High Thermal Conductivity

The thermal conductivity of AlN reaches 170–200 W/(m·K)—8 to 10 times that of traditional aluminum oxide (Al₂O₃) ceramic. This exceptional thermal performance enables rapid transfer of heat generated by electronic components to the heat dissipation system, significantly lowering the chip junction temperature. In turn, this improves the reliability of equipment and extends its service life, addressing a critical pain point in high-power electronic applications.

2. Low Thermal Expansion Coefficient (CTE) – Matched to Semiconductor Materials

AlN has a CTE of 4.5×10⁻⁶/℃, which is highly compatible with semiconductor materials like silicon (Si) and silicon carbide (SiC). This close matching minimizes thermal stress between the substrate and semiconductor chips during thermal cycling, greatly reducing the risk of stress-induced cracking. This makes AlN ceramic substrates ideal for high-temperature and high-power scenarios where thermal stability is paramount.

3. Excellent Electrical Insulation & High-Frequency Performance

AlN exhibits a low dielectric constant (8.8–9.5) and extremely low dielectric loss (<0.001). These properties effectively reduce signal delay and energy loss during high-frequency signal transmission, ensuring signal integrity even in high-speed communication systems. Consequently, it has become an ideal choice for high-frequency devices such as 5G base stations and millimeter-wave radars.

4. High Mechanical Strength & Corrosion Resistance

AlN ceramic boasts high hardness and strong chemical stability. When combined with advanced copper cladding processes—such as Direct Bonding of Copper (DBC) or Active Metal Brazing (AMB)—it forms a tight, durable bond between the copper layer and the ceramic substrate. The resulting material is resistant to high temperatures and corrosion, enabling long-term stable operation in harsh environments (e.g., high humidity, chemical exposure, or extreme temperature fluctuations).

Typical Applications

1. Electric Vehicle Inverters

In electric vehicle inverters, a 1mm-thick AlN substrate serves as the heat dissipation carrier for IGBT modules. This application reduces the operating temperature of the module by 20–30℃, directly enhancing the inverter’s energy conversion efficiency and extending the overall service life of the power system.

2. GaN Power Amplifier Modules in 5G Base Stations

GaN power amplifiers in 5G base stations generate significant heat during high-frequency operation, which can disrupt signal stability. AlN substrates address this challenge by efficiently dissipating heat, while their low dielectric loss ensures minimal signal interference—critical for maintaining the performance of 5G communication networks.

3. Industrial Laser Cutting Machines

In industrial CO₂ laser cutting machines, AlN substrates are used for heat dissipation of the laser’s drive circuit. By preventing excessive temperature rise in the circuit, they avoid beam drift caused by thermal deformation, ensuring the precision and consistency of laser cutting operations.

Future Trends

With the widespread adoption of third-generation semiconductors (e.g., SiC, GaN), the demand for efficient heat dissipation solutions in high-power-density devices has grown exponentially. AlN ceramic circuit boards are poised to expand their application scope in the following key fields:

New Energy Sector: They will be increasingly used in photovoltaic inverters and energy storage systems, where reliable heat management is essential for optimizing energy efficiency and system longevity.

Artificial Intelligence (AI): As AI chips grow in power density, AlN substrates will serve as high-performance heat dissipation carrier boards, supporting the stable operation of AI servers and computing clusters.

6G Communications: For terahertz-frequency band circuits—critical for 6G technology—AlN substrates will act as core substrate materials, leveraging their low dielectric loss and high thermal conductivity to ensure signal integrity and thermal stability.