Home

-

Antenna PCB

-

Rogers IsoClad 917 High Frequency PCB Rogers non-woven fiberglass/PTFE PCB Materials for Antennas Application

Home

-

Antenna PCB

-

Rogers IsoClad 917 High Frequency PCB Rogers non-woven fiberglass/PTFE PCB Materials for Antennas Application

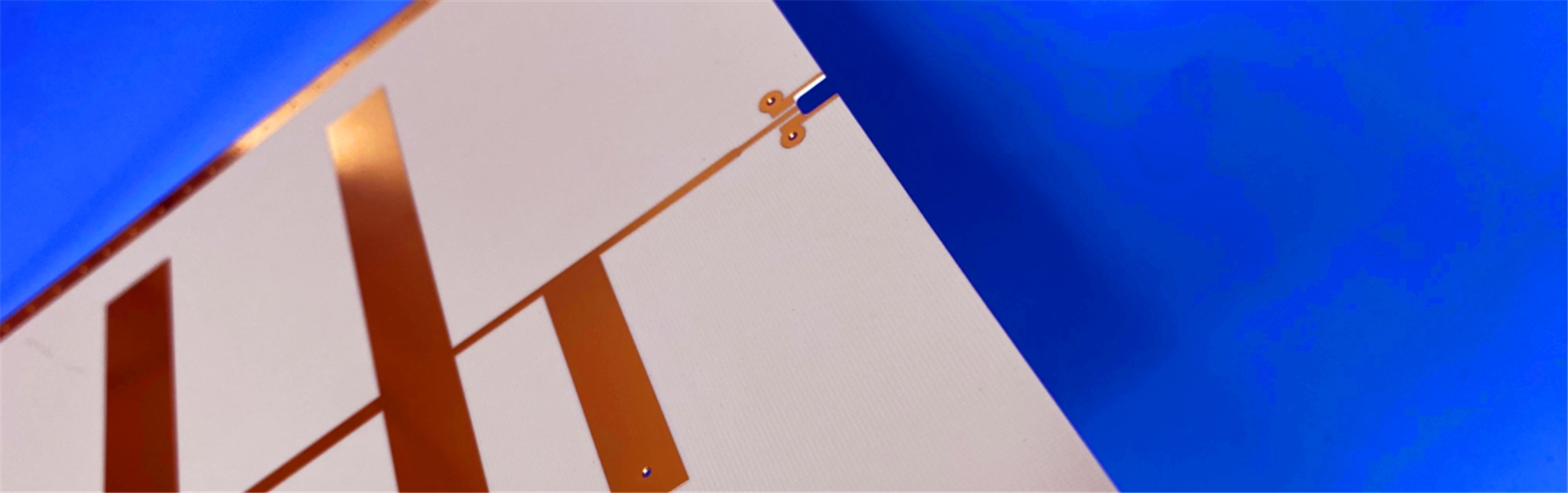

Rogers IsoClad 917 High Frequency PCB Rogers non-woven fiberglass/PTFE PCB Materials for Antennas Application

Printed Circuit Boards are custom-made products; the images and specifications provided are for reference only.

Brief Introduction

Rogers IsoClad 917 PCBs are non-woven fiberglass/polytetrafluoroethylene (PTFE) composite materials. To deliver an ultra-low dielectric constant—either 2.17 or 2.20—and a dissipation factor of 0.0013, these laminates utilize a low-proportion fiberglass-to-PTFE ratio.

A key advantage of IsoClad 917 laminate lies in its material and manufacturing design: it incorporates longer random fibers, paired with a proprietary production process. This combination enables the laminate to outperform competitors in the same product class, offering superior dimensional stability and more consistent dielectric constant across the material.

As a non-woven fiberglass-reinforced solution, IsoClad 917 PCB is less rigid compared to woven fiberglass-based laminates. This inherent flexibility makes it ideal for applications where the final printed circuit board (PCB) requires shaping or bending—such as in conformal antennas and wrap-around antennas.

.jpg)

Features

- Low dielectric constant (Dk) of 2.17 or 2.20

2. Low dissipation factor of .0013 at 10GHz

3. Extremely low loss

4. Low moisture absorption

5. Highly Isotropic in X, Y and Z Directions

Typical Applications:

- Conformal Antennas

2. Stripline and Microstrip Circuits

3. Guidance Systems

4. Radar Systems

Our PCB Capability (IsoClad 917)

| PCB Capability (IsoClad 917) | |

| PCB Material: | Non-woven Fiberglass / PTFE Composites |

| Designation: | IsoClad 917 |

| Dielectric constant: | 2.17 or 2.20 (10 GHz) |

| Dissipation factor | 0.0013 (10 GHz) |

| Layer count: | Single Sided, Double Sided, Multi-layer PCB, Hybrid PCB |

| Copper weight: | 1oz (35µm), 2oz (70µm) |

| Dielectric thickness | 20mil (0.508mm), 31mil (0.787mm), 62mil (1.575mm) |

| PCB size: | ≤400mm X 500mm |

| Solder mask: | Green, Black, Blue, Yellow, Red etc. |

| Surface finish: | ENIG(immersion gold), HASL, Immersion silver, Immersion tin, ENEPIG, OSP, Bare copper, Pure gold plated etc.. |

Appendix: Typical Values of IsoClad 917

| Typical Properties: IsoClad 917 | |||

| Property | IsoClad 917 | Condition | Test Method |

| Dielectric Constant @ 10 GHz | 2.17, 2.20 | C23/50 | IPC TM-650 2.5.5.5 |

| Dissipation Factor @ 10 GHz | 0.0013 | C23/50 | IPC TM-650 2.5.5.5 |

| Thermal Coefficient of Er (ppm/°C) | -157 | -10°C to +140°C | IPC TM-650 2.5.5.5 Adapted |

| Peel Strength (lbs.per inch) | 10 | After Thermal | IPC TM-650 2.4.8 |

| Volume Resistivity (MΩ-cm) | 1.5 x 10 10 | C96/35/90 | IPC TM-650 2.5.17.1 |

| Surface Resistivity (MΩ) | 1.0 x 10 9 | C96/35/90 | IPC TM-650 2.5.17.1 |

| Arc Resistance (seconds) | >180 | D48/50 | ASTM D-495 |

| Tensile Modulus (kpsi) | 133, 120 | A, 23°C | ASTM D-638 |

| Tensile Strength (kpsi) | 4.3, 3.8 | A, 23°C | ASTM D-882 |

| Compressive Modulus (kpsi) | 182 | A, 23°C | ASTM D-695 |

| Flexural Modulus (kpsi) | 213 | A, 23°C | ASTM D-790 |

| Dielectric Breakdown (kv) | >45 | D48/50 | ASTM D-149 |

| Density (g/cm3) | 2.23 | A, 23°C | ASTM D-792 Method A |

| Water Absorption (%) | 0.04 | E1/105 + D24/23 | MIL-S-13949H 3.7.7 IPC TM-650 2.6.2.2 |

| Coefficient of Thermal | 0°C to 100°C | IPC TM-650 2.4.24 | |

| Expansion (ppm/°C) | Mettler 3000 | ||

| X Axis | 46 | Thermomechanical | |

| Y Axis | 47 | Analyzer | |

| Z Axis | 236 | ||

| Thermal Conductivity (W/mK) | 0.263 | 100°C | ASTM E-1225 |

| Outgassing | 125°C, ≤10-6 torr | ||

| Total Mass Loss (%) | 0.02 | Maximum 1.00% | |

| Collected Volatile | 0.00 | Maximum 0.10% | |

| Condensable Material (%) | |||

| Water Vapor Regain (%) | 0.02 | ||

| Visible Condensate (±) | NO | ||

| Flammability | Meets requirements of UL94-V0 |

C48/23/50, E24/125 | UL 94 Vertical Burn IPC TM-650 2.3.10 |