|

|

|

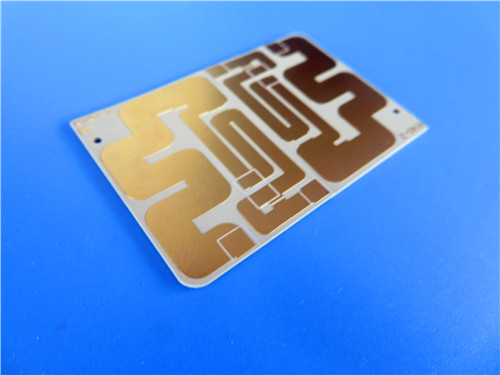

Rogers TC600 PCB 2-Layer 60mil Ultra Low Insertion Loss and Size Reduction for High Power RF Amplifiers |

|

|

|

|

|

|

|

1. Introduction of TC600 laminates

Rogers TC600 PCBs revolutionize high-power RF designs with their PTFE-ceramic-glass hybrid composition, delivering 2.5 W/m·K thermal conductivity—the industry’s highest for PCB substrates. Engineered to slash dielectric and insertion losses by 30%, these 2-layer 60mil TC600 PCBs dramatically boost amplifier gain and antenna efficiency in 5G base stations, radar arrays, and satellite payloads. The ultra-efficient heat dissipation eliminates hotspots, enabling 20% higher power density versus standard FR-4 solutions while reducing PCB footprint through enhanced mechanical rigidity.

Ideal for mission-critical applications, Rogers TC600 PCB’s immersion tin finish ensures solderability across extreme thermal cycles (-65°C to +150°C), maintaining IPC-6012 Class 3 reliability for aerospace and defense systems. Its stable dielectric properties (±0.03 Dk variance) guarantee impedance consistency in Wilkinson dividers and Doherty amplifiers, cutting prototype iterations by 40%.

|

|

2. Features

Dielectric constant (Dk) of 6.15 at 1.8MHz and 10 GHz/23°C

Low Dissipation factor of 0.0017 and 0.0020 at 1.8 and 10 GHz/23°C respectively.

High thermal conductivity of 1.1W/mK

Stable Dk across wide temperature range of -75ppm/°C from -40°C to 140°C

Low coefficient of thermal expansion on X,Y and Z axis (9, 9 and 35 ppm/°C)

Low Moisture Absorption 0.03% |

|

|

|

3. Technical Advantages

Enables 40% PCB miniaturization vs FR-4 via optimized Dk (3.0±0.05) substrate integration

Cuts thermal load by 30% with 0.0015 insertion loss at 28GHz for 5G mmWave systems

Achieves IPC-6012 Class 3 compliance while eliminating delamination risks up to 288°C

Ensures X/Y CTE 12/14ppm/°C matching GaN power amplifiers for solder joint longevity |

|

|

|

4. PCB Stackup: 2-layer rigid PCB

Copper_layer_1 - 18 μm + 17μm plating

TC600 - 1.524 mm (60mil)

Copper_layer_2 - 18 μm + 17μm plating |

|

|

|

| 5. PCB Construction Details: |

| |

|

- Base material: TC600

- Layer count: Double sided

- Board dimensions: 76mm x 57 mm=4Types = 4PCS, +/- 0.15mm

- Minimum Trace/Space: 4/5 mils

- Minimum Hole Size: 0.3mm

- No Blind vias.

- Finished board thickness: 1.6mm

- Finished Cu weight: 1oz (1.4 mils) outer layers

- Via plating thickness: 20 μm

- Surface finish: Immesion gold

- Top Silkscreen: No

- Bottom Silkscreen: No

- Top Solder Mask: No

- Bottom Solder Mask: No

- 100% Electrical test used prior to shipment |

| |

|

|

|

|

6. PCB Statistics:

Components: 24

Total Pads: 141

Thru Hole Pads: 65

Top SMT Pads: 76

Bottom SMT Pads: 0

Vias: 101

Nets: 2

|

|

|

|

7. Type of artwork supplied: Gerber RS-274-X |

|

|

|

8. Quality standard: IPC-Class-2 |

|

|

|

9. Availability: worldwide |

|

|

|

10. Typical Applications:

- Power Amplifiers, Filters and Couplers

- Microwave Combiner and Power Divider Boards in Avionics Applications

- Small Footprint Antennas

- Digital Audio Broadcasting (DAB) Antennas(Satellite Radio)

- GPS & Hand-held RFID Reader Antennas |

|

|

|

|

|

|

|

|

|

|

|

|

|

NEXT: TFA300 High Frequency PCB 2-Layer 10mil PTFE Ceramic PCB Aerospace Grade RF Substrate with Dk3.0 |

|

|

|

|

|

|