|

|

|

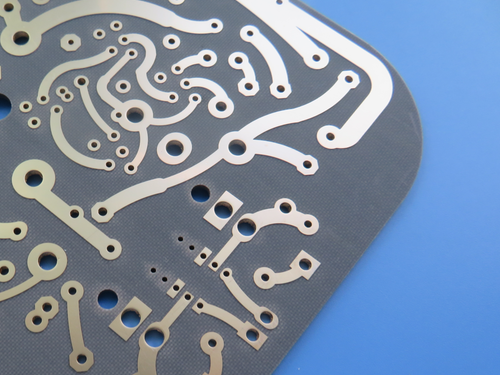

F4BM220 PCB 2-Layer 1.575mm Precision PTFE Material for Low Loss and PIM Critical Applications From Wangling |

|

|

|

|

|

|

|

1. Introduction of F4BM220

Wangling's F4BM220 laminates represent a scientifically engineered PTFE composite solution, combining fiberglass cloth with polytetrafluoroethylene resin and film to deliver superior electrical performance over conventional F4B220 materials. These high-performance laminates feature reduced dielectric loss, enhanced insulation resistance, and improved stability - providing a cost-competitive alternative to imported equivalents.

The series offers two optimized copper foil configurations: F4BM220 with ED copper for standard applications, and F4BME220 featuring reverse-treated foil (RTF) for designs requiring exceptional PIM performance, precision line control, and minimized conductor loss. Through precise adjustment of the PTFE-to-fiberglass ratio, both variants maintain excellent dielectric constant control while delivering industry-leading dimensional stability and thermal performance - with fiberglass content strategically balanced to optimize the thermal expansion coefficient, temperature drift, and loss characteristics.

|

|

2. Features (F4BM220) |

|

- Dielectric constant (Dk) of 2.2±0.04 at 10GHz

- Dissipation factor of .001 at 10GHz

- CTE x-axis of 25 ppm/°C, CTE y-axis of 34 ppm/°C, CTE z-axis of 240 ppm/°C, -55°C to 288°C

- Thermal coefficient of Dk at-142 ppm/°C, -55°C to 150°C

- Moisture absorption of ≤0.08%

- Flammability of UL-94 V0 |

|

|

|

3. PCB Stack-up: 2-layer Rigid PCB

Copper_layer_1 - 35 μm

F4BM220 Core - 1.575 mm

Copper_layer_2 - 35 μm

|

|

|

|

| 4. PCB Construction details: |

| |

| - Base material: F4BM220

- Layer count: 2 layers

- Board dimensions: 130.5mm x 103 mm=1PCS, +/- 0.15mm

- Minimum Trace/Space: 4/6 mils

- Minimum Hole Size: 0.3mm

- No Blind vias.

- Finished board thickness: 1.7mm

- Finished Cu weight: 1oz (1.4 mils) outer layers

- Via plating thickness: 20 μm

- Surface finish: Electroless Nickle Immersion Gold (ENIG)

- Top Silkscreen: No

- Bottom Silkscreen: No

- Top Solder Mask: No

- Bottom Solder Mask: No

- 100% Electrical test used prior to shipment |

| |

|

|

| |

|

|

|

5. PCB Statistics:

Components: 43

Total Pads: 94

Thru Hole Pads: 56

Top SMT Pads: 38

Bottom SMT Pads: 0

Vias: 51

Nets: 2

|

|

|

|

6. Type of artwork supplied: Gerber RS-274-X |

|

|

|

7. Quality standard: IPC-Class-2 |

|

|

|

8. Availability: worldwide |

|

|

|

9. Some Typical Applications:

- Microwave, RF, and radar systems

- Phase shifters

- Power dividers, couplers, combiners

- Feed networks

- Phase-sensitive antennas, phased array antennas

- Satellite communications

- Base station antennas |

|

|

|

|

|

|

|

|

|

|

|

|

|

NEXT: F4BTMS430 2-Layer PCB Wangling 3.175mm Aerospace Grade Ceramic PTFE Composite with Enhanced Dk Range and Stability |

|

|

|

|

|

|