|

|

|

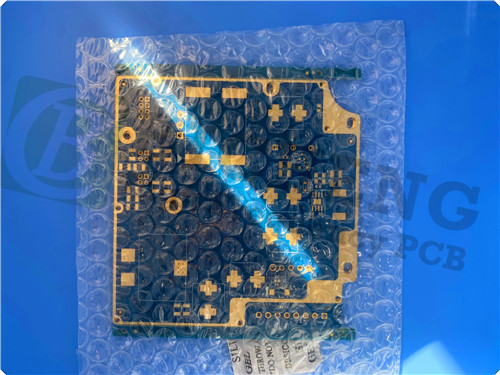

6-Layer 1.6mm High Tg180°C ISOLA 370 HR High Frequency PCB FR-4 Material |

|

|

|

|

|

|

|

1. Introduction of ISOLA 370HR

370HR laminates and prepregs, designed by Polyclad, utilize a patented high-performance FR-4 multifunctional epoxy resin system with a Tg of 180°C. This system is specifically tailored for multilayer Printed Circuit Board (PCB) applications where exceptional thermal performance and reliability are paramount. Manufactured with high-quality E-glass fabric, 370HR laminates and prepregs offer superior resistance to Conductive Anodic Filament (CAF). They deliver outstanding thermal performance, characterized by a low Coefficient of Thermal Expansion (CTE), along with mechanical, chemical, and moisture resistance properties that match or surpass traditional FR-4 materials.

|

|

370HR has been incorporated into thousands of PCB designs and has proven to be unparalleled in terms of thermal reliability, CAF performance, processing ease, and consistent performance in sequential lamination designs. |

|

|

|

2. Properties

- Glass Transition Temperature (Tg) by DSC is 180°C

- Decomposition Temperature (Td) by TGA @ 5% weight loss is 340°C

- Time to Delaminate, measured by TMA (with copper removed), is 60 minutes at 260°C and 30 minutes at 288°C

- Coefficient of thermal expansion (CTE) , pre-Tg: Z-Axis is 45ppm/°C, X/Y-Axis is 13/14ppm/°C

- Thermal Conductivity is 0.4W/MK

- Dielectric Constant (DK) or Permittivity is 3.92 at 5 GHz and 10 GHz, 4.24 at 100 MHz, 4.17 at 1 GHz, and 4.04 at 2 GHz

- Loss Tangent (Df) is 0.025 at 5 GHz and 10 GHz, 0.015 at 100 MHz, 0.0161 at 1 GHz, and 0.021 at 2 GHz

- Dielectric Breakdown Voltage is greater than 50kV

- Comparative Tracking Index (CTI) ranges from 175V to 249V

- Moisture Absorption is 0.15%

- Flammability (Laminate & laminated prepreg) is UL94-V0

|

|

|

|

3. Attributes

- High thermal reliability

- High density interconnect |

|

|

|

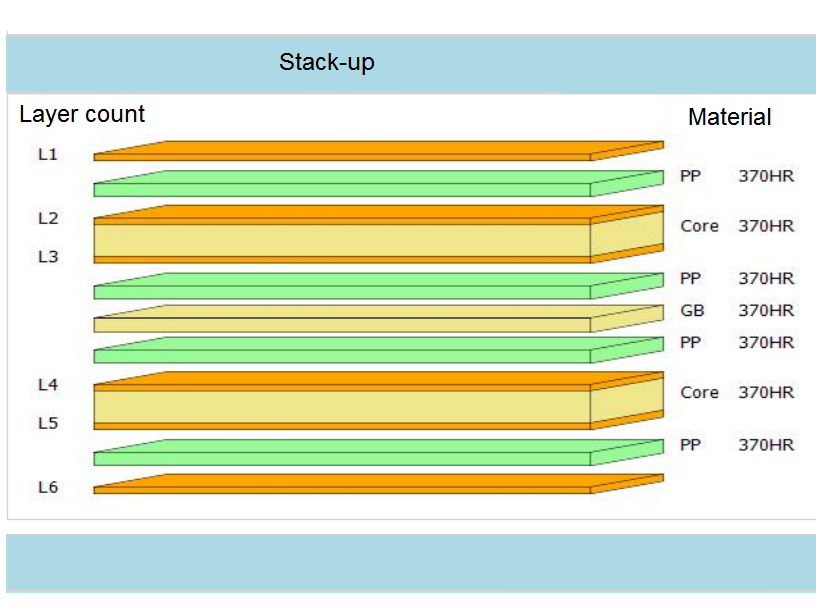

4. 6-Layer PCB stackup (370HR)

Layer Filename Thickness(mil)

Signal 1 Top 1.4 6.0

Plane 2 GND 1.4 6.0

Signal 3 SIG1 1.4 29.6

Signal 4 SIG2 1.4 6.0

Plane 5 PWR 1.4 6.0

Signal 6 Bottom 1.4

Total 62.0 mil

|

|

|

|

| 5. PCB Construction Details: |

| |

| - Board dimensions: 40mm x 55 mm=1PCS, +/- 0.15mm

- Minimum Trace/Space: 4/4 mils

- Minimum Hole Size: 0.2mm

- No Blind vias.

- Finished board thickness: 1.6mm

- Finished Cu weight inner layer/outer layer: 1oz (1.4 mils)

- Via plating thickness: 20 μm

- Surface finish: ENIG

- Top Silkscreen: White

- Bottom Silkscreen: White

- Top Solder Mask: Green

- Bottom Solder Mask: Green

- Top layer 10mil traces 50 ohm impedance control

- 100% Electrical test used prior to shipment |

| |

| |

| |

| |

| |

| |

|

|

|

|

|

|

6. PCB Statistics:

Components: 31

Total Pads: 46

Thru Hole Pads: 29

Top SMT Pads: 17

Bottom SMT Pads: 0

Vias: 24

Nets: 5 |

|

|

|

7. Type of artwork supplied: Gerber RS-274-X |

|

|

|

8. Accepted standard: IPC-Class-2 |

|

|

|

9. Availability: worldwide |

|

|

|

10. Some Typical Applications:

-Computing, Storage, and Peripheral Devices

-Consumer Electronic Devices

-Network and Communication Systems

-Medical, Industrial, and Instrumentation Technologies

-Automotive and Transportation Systems

-Aerospace and Defense Applications |

|

|

|

|

|

|

|

|

|

|

|

|

|

NEXT: 1.524mm 2-layer Fiberglass Cloth and PTFE Composites Wangling F4BM300 for Satellite Communications |

|

|

|

|

|

|