|

|

|

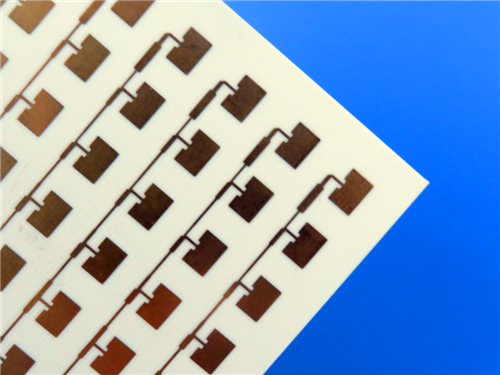

4mil 2-Layer Rogers RO4350B PCB Exceptional Thermal Stability and Dimensional Control for Reliable Plated Through Holes |

|

|

|

|

|

|

|

1. Introduction of RO4350B

Rogers RO4350B materials are advanced, proprietary laminates combining woven glass reinforcement with hydrocarbon/ceramic substrates. Designed to deliver electrical performance comparable to PTFE/woven glass and the manufacturability of epoxy/glass, RO4350B offers a unique balance of high-frequency capabilities and cost-effective fabrication.

|

|

|

|

RO4350B laminates provide exceptional control over dielectric constant (Dk) and low signal loss, while maintaining compatibility with standard epoxy/glass processing methods—all at a fraction of the cost of traditional microwave laminates. Unlike PTFE-based materials, RO4350B requires no special through-hole treatments or handling procedures, simplifying production and reducing costs. These materials are UL 94 V-0 rated, making them ideal for active devices and high-power RF designs. |

|

|

|

RO4350B's thermal coefficient of expansion (CTE) is engineered to match copper, ensuring excellent dimensional stability—a critical feature for mixed dielectric multi-layer boards. With a low Z-axis CTE, RO4350B delivers reliable plated through-hole performance, even under severe thermal shock conditions. Additionally, its high glass transition temperature (Tg >280°C / 536°F) ensures stable expansion characteristics across a wide range of processing temperatures. |

|

|

|

2. Features

- Dielectric Constant of DK 3.48 +/-0.05 at 10GHz/23°C

- Dissipation Factor of 0.0037 at 10GHz/23°C

- Thermal Conductivity 0.69 W/m/°K

- X axis CTE of 10 ppm/°C, Y CTE of 12 ppm/°C, Z CTE of 32 ppm/°C

- High Tg value of >280 °C

- Low water absorption of 0.06%

|

|

|

|

3. Benefits

Perfect for Multi-Layer Board (MLB) Designs

Processes Like FR-4 with Reduced Fabrication Costs

Exceptional Dimensional Stability for Precision Applications

Competitive Pricing for Superior Value |

|

|

|

4. PCB Stackup: 2-layer rigid PCB

Copper_layer_1 - 35 μm

Rogers RO4350B Core - 0.102 mm (4mil)

Copper_layer_2 - 35 μm |

|

| 5. PCB Construction Details: |

| |

| - Board dimensions: 340 mm x 340 mm=1PCS, +/- 0.15mm

- Minimum Trace/Space: 4/5 mils

- Minimum Hole Size: 0.25mm

- No Blind vias.

- Finished board thickness: 0.2mm

- Finished Cu weight: 1oz (1.4 mils) outer layers

- Via plating thickness: 20 μm

- Surface finish: Immersion Gold

- Top Silkscreen: No

- Bottom Silkscreen: No

- Top Solder Mask: No

- Bottom Solder Mask: No

- 100% Electrical test used prior to shipment |

| |

|

|

|

|

6. PCB Statistics:

Components: 16

Total Pads: 60

Thru Hole Pads: 38

Top SMT Pads: 22

Bottom SMT Pads: 0

Vias: 32

Nets: 2

|

|

|

|

7. Type of artwork supplied: Gerber RS-274-X |

|

|

|

8. Quality standard: IPC-Class-2 |

|

|

|

9. Availability: worldwide |

|

|

|

10. Some Typical Applications:

- Cellular Base Station Antennas and Power Amplifiers

- RF Identification Tags

- Automotive Radar and Sensors

- LNB's for Direct Broadcast Satellites

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NEXT: RT/duroid 6035HTC 2-Layer 20mil PCB Ceramic Filled PTFE for High Power RF and Microwave with Low Drilling Costs |

|

|

|

|

|

|