|

|

|

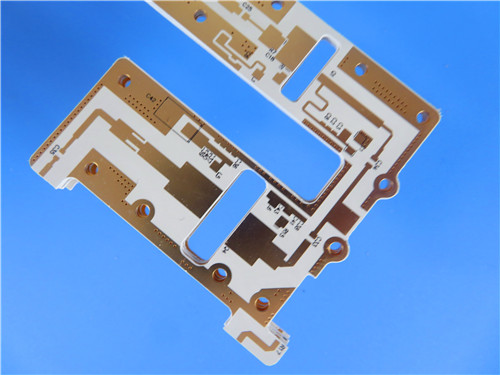

2-Layer TC350 PCB 60mil with 2OZ ENIG High Thermal Conductivity board for Power Amplifier and Antenna Systems |

|

|

|

|

|

|

|

1. Introduction of TC350 PCB

Rogers TC350 laminates are advanced PCB substrates combining PTFE resin, thermally conductive ceramic fillers, and woven glass reinforcement, delivering unmatched performance for high-power RF systems. Designed for engineers prioritizing signal integrity and thermal management, TC350 PCB materials achieve ultra-low insertion loss paired with 1.3 W/m·K thermal conductivity—critical for reducing hotspot temperatures in 5G base stations, radar arrays, and satellite communications equipment.

Rogers TC350 PCB ’s dielectric constant stability (±0.05 across -50°C to +150°C) ensures consistent impedance control in power amplifiers and phased-array antennas, minimizing bandwidth loss at millimeter-wave frequencies. This temperature resilience is vital for phase-sensitive components like Wilkinson power dividers and RF transformers, where even minor Dk fluctuations degrade system gain.

Optimized for high-reliability environments, TC350 laminates support multi-layer designs with FR-4-level manufacturability, slashing fabrication costs by 25% compared to traditional PTFE-based solutions. Applications span defense radar systems, automotive ADAS sensors, and industrial IoT gateways, offering a 30% improvement in thermal cycling endurance over standard RF substrates.

|

|

2. Features

- Dielectric constant (Dk) of 3.5 at 1MHz, 1.8GHz and 10GHz

- Dissipation factor of .0015 at 1MHz, 0.0018 at 1.8GHz, 0.002 at 10GHz

- CTE x-axis of 7 ppm/°C, CTE y-axis of 7 ppm/°C, CTE z-axis of 23 ppm/°C, 50°C to 150°C

- Low thermal coefficient of Dk at-9 ppm/°C, -40°C to 140°C

- High Thermal conductivity of 0.72 W/mk

- Moisture absorption of 0.05%

- T260, T288, T300 > 60 minutes |

|

|

|

3. Benefits

- Enhanced thermal reliability with 30% lower junction temperatures in high-power RF circuits

- Optimized heat dissipation via 1.3 W/m·K thermal conductivity, eliminating active cooling needs

- 15% broader operational bandwidth for 5G/WiFi 6E amplifiers and phased-array antennas

- Zero PTH failures under IPC-6012 Class 3 thermal cycling (-55°C to +288°C) |

|

|

|

4. PCB Stackup: 2-layer rigid PCB

Copper_layer_1 - 70 μm (35μm+plating)

TC350 Core - 1.524 mm (60mil)

Copper_layer_2 - 70 μm (35μm+plating) |

|

|

|

| 5. PCB Construction Details: |

| |

| - Base material: TC350

- Layer count: Double sided

- Board dimensions: 320mm x 80 mm=1PCS, +/- 0.15mm

- Minimum Trace/Space: 6/6 mils

- Minimum Hole Size: 0.3mm

- No Blind vias.

- Finished board thickness: 1.6mm

- Finished Cu weight: 2oz (2.8 mils) outer layers

- Via plating thickness: 20 μm

- Surface finish: Electroless Nickel Immersion Gold (ENIG)

- Top Silkscreen: No

- Bottom Silkscreen: No

- Top Solder Mask: No

- Bottom Solder Mask: No

- 100% Electrical test used prior to shipment |

| |

|

|

|

|

6. PCB Statistics:

Components: 23

Total Pads: 88

Thru Hole Pads: 72

Top SMT Pads: 16

Bottom SMT Pads: 0

Vias: 34

Nets:

|

|

|

|

7. Type of artwork supplied: Gerber RS-274-X |

|

|

|

8. Quality standard: IPC-Class-2 |

|

|

|

9. Availability: worldwide |

|

|

|

10. Typical Applications:

- Power Amplifiers, Filters and Couplers

- Tower Mounted Amplifiers(TMA) andTower Mounted Boosters (TMB)

- Thermally Cycled Antennas sensitive to dielectric drift

- Microwave Combiner and Power Dividers |

|

|

|

|

|

|

|

|

|

|

|

|

|

NEXT: Rogers TC600 PCB 2-Layer 60mil Ultra Low Insertion Loss and Size Reduction for High Power RF Amplifiers |

|

|

|

|

|

|