| |

|

| |

|

|

|

|

|

| |

|

What is Thermal Conductivity in High Frequency PCB? |

|

|

|

| |

|

1. The Introduction of Thermal Management |

|

|

|

| |

|

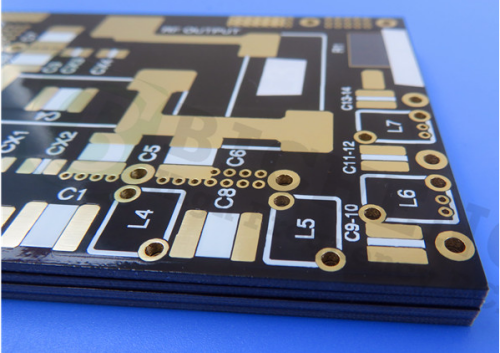

IThermal conductivity refers to a material's ability to conduct heat. In high-frequency PCBs, effective thermal management is essential because increased operating frequencies can lead to higher temperatures. If heat is not dissipated efficiently, it can result in signal integrity issues, reduced performance, and shorter lifespan of the PCB. Therefore, optimizing thermal conductivity is crucial for enhancing reliability and ensuring the proper functioning of high-frequency circuits. |

|

|

| |

|

|

|

|

| |

|

2. Material Selection and Its Impact |

|

|

| |

|

The choice of materials used in high-frequency PCBs greatly affects thermal conductivity. Materials such as copper, commonly used for traces, and specific dielectric materials can enhance thermal performance. For instance, materials with high thermal conductivity allow for better heat dissipation, which is vital for maintaining the integrity of high-frequency signals. By selecting materials that exhibit both high thermal conductivity and low dielectric loss, manufacturers can improve the overall performance of high-frequency PCBs. |

|

|

| |

|

|

|

|

| |

|

3. Design Strategies for Improving Thermal Conductivity |

|

|

| |

|

Design strategies also play a significant role in managing thermal conductivity in high-frequency PCBs. Effective thermal management can be achieved by optimizing the layout of the PCB, ensuring proper spacing between components, and incorporating heat sinks or thermal vias. These strategies help distribute heat more evenly across the board, reducing hotspots that could compromise performance. |

|

|

| |

|

|

|

|

| |

|

4. Highly Thermally Conductive Rogers TC350™ Laminates |

|

|

| |

|

TC350 laminates are PCB substrates composed of PTFE, woven glass reinforcement, and highly thermally conductive ceramic fillers. These materials offer designers a unique combination of low insertion loss and superior thermal conductivity at 1.0 W/mK,, resulting in enhanced reliability and lower operating temperatures in high-power applications. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

4-1.Standard Offerings of Rogers TC350 laminates |

|

|

| |

|

Standard Thicknesses |

0.010"(0.252mm) +/- 0.0007"

0.020"(0.508mm) +/- 0.0015"

0.030"(0.762mm) +/- 0.0020"

0.060"(1.524mm) +/- 0.0030" |

Standard Panel Sizes |

0.010": 18" X 12" (457 X 305mm)

18" X 24" (457 X 610mm)

All Other Thicknesses:

12" X 18" (305 X 457mm)

24" X 18" (610 X 457mm) |

Standard Claddings |

0.010": Reverse Treated Electrodeposited Copper Foil

1/2 oz. (18μm) and 1 oz. (35μm)

All Other Thicknesses:Electrodeposited Copper Foil1 1/2 oz. (18μm) and 1 oz. (35μm)

(including Reverse Treated) |

|

|

|

| |

|

|

|

|

| |

|

4.1 Features

Dielectric Constant: 3.5

Thermal Conductivity: High at 0.72 W/m-K

Thermal Coefficient of DK: Low at -9 ppm/°C within the range of -40°C to 140°C

Loss Tangent: Low at 0.002 at 10 GHz

Coefficient of Thermal Expansion: Low on the X and Y axes (7 ppm/°C) and slightly higher on the Z axis (23 ppm/°C) |

|

|

| |

|

|

|

|

| |

|

4.2 Benefits

Enhanced Reliability: Strong peel strength minimizes the risk of delamination, while reduced junction temperature further contributes to the longevity of the PCB.

Efficient Heat Dissipation: Excellent thermal management capabilities.

Optimized Bandwidth Utilization: Increased efficiency for amplifiers and antennas.

Reliable Plated Through Holes: Unsurpassed reliability for plated through holes. |

|

|

| |

|

4.3 Typical Applications

Power Amplifiers, Filters and Couplers

Tower Mounted Amplifiers(TMA) and Tower Mounted Boosters (TMB)

Thermally Cycled Antennas sensitive to dielectric drift

Microwave Combiner and Power Dividers |

|

|

| |

|

5. Conclusion |

|

|

| |

|

In conclusion, thermal conductivity is a vital factor in the performance and reliability of high-frequency PCBs. By prioritizing material selection and implementing effective design strategies, manufacturers can enhance thermal management, which leads to improved signal integrity and reduced failure rates. As one insightful observation states, “Optimizing thermal conductivity not only boosts high-frequency PCB performance but also prolongs their lifespan.” |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|