| |

|

| |

|

|

|

|

|

| |

|

What is Thermal Coefficient of DK in High Frequency PCB? |

|

|

|

| |

|

1. Definition and Importance |

|

|

|

| |

|

IThe thermal coefficient of DK (TCDk) refers to the change in the dielectric constant of high-frequency PCB materials with temperature. It plays a crucial role in the performance of high-frequency PCBs, serving as a bridge connecting technology and innovation in the electronics world. Understanding the importance of the thermal coefficient of DK is akin to finding the key to unlocking exceptional performance. |

|

|

| |

|

|

|

|

| |

|

2. Relationship Between High-Frequency PCB Performance and TCDk |

|

|

| |

|

The performance of high-frequency PCB hinges on signal transmission stability and efficiency. The thermal coefficient of DK is directly related to thermal stability. A lower thermal coefficient of DK allows the PCB to maintain a relatively stable dielectric constant during temperature fluctuations, ensuring uninterrupted signal transmission. Conversely, a higher TCDk can lead to signal degradation and distortion. |

|

|

| |

|

|

|

|

| |

|

3. TCDk vs. Temperature Graph |

|

|

| |

|

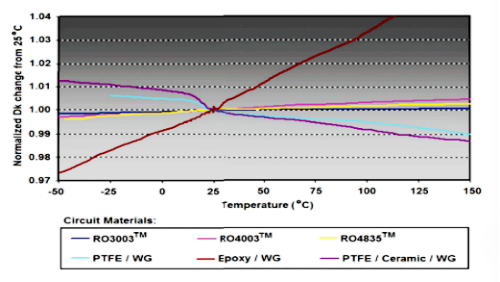

The two tables below illustrates the changes in the thermal coefficient of DK at varying temperatures for Taconic, Rogers, and Wangling materials, offering a clear comparison of their performance stability in high-frequency PCB applications. |

|

|

| |

|

|

|

|

| |

|

3-1.TCDk Value Comparison Table |

|

|

| |

|

Temperature (°C) |

Taconic DK Value |

Rogers DK Value |

Wangling DK Value |

25 |

3.2 |

3.0 |

3.1 |

50 |

3.2 |

3.1 |

3.1 |

85 |

3.3 |

3.2 |

3.2 |

100 |

3.4 |

3.3 |

3.3 |

125 |

3.5 |

3.4 |

3.4 |

|

|

|

| |

|

|

|

|

| |

|

Notes

- Taconic Material : Shows slight increases in DK values at high temperatures, indicating stability under temperature changes.

- Rogers Material: Maintains small DK value changes across temperatures, showcasing good thermal stability ideal for high-frequency applications.

- Wangling Material: Exhibits controllable DK values similar to Taconic and Rogers, suitable for various frequency and temperature conditions.

|

|

|

| |

|

|

|

|

| |

|

4. Features of Leading high-frequency Material Suppliers |

|

|

| |

|

4.1 Taconic

Taconic materials exhibit excellent thermal coefficient of DK performance. Their materials maintain a low DK thermal coefficient, allowing for a stable dielectric constant under varying temperatures. This characteristic ensures stable and efficient signal transmission in high-frequency communication and radar systems.

4.2 Rogers

Rogers materials are known for their effective control of the DK thermal coefficient. With minimal changes across a wide temperature range, Rogers materials significantly reduce signal transmission issues related to temperature fluctuations, making them suitable for high-performance microwave and RF applications.

|

|

|

| |

|

4-1. Schematic diagram of Rogers high-frequency PCB's DK value varying with temperature |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

Based on the data comparison, we will find that Rogers RO3003 exhibits an exceptionally stable dielectric constant thermal coefficient. This stability, combined with consistent mechanical properties, allows designers to create multi-layer board designs without encountering issues such as warpage or reliability concerns. |

|

|

| |

|

|

|

|

| |

|

4.2.1 The introduction of Rogers RO3003

Material Composition

Rogers RO3003 is a high-frequency circuit material made from ceramic-filled PTFE composites.

Circuit Board Specifications

The 2-layer Rogers 3003 10mil circuit board features:

Dielectric Constant (DK): 3.0

Dissipation Factor (DF): 0.001

Thermal Expansion Properties

Coefficient of Thermal Expansion (CTE):

X and Y Axes: 17 ppm/℃

Z Axis: 24 ppm/℃

Etching Characteristics

Etch Shrinkage: Typical shrinkage is less than 0.5 mils per inch after the etch and bake process.

Reliability

The thermal and mechanical stability of Rogers RO3003 contributes to exceptional reliability for plated through-holes, even in demanding environments.

Application

A wide range of microwave and RF applications. |

|

|

| |

|

|

|

|

| |

|

4-2. Rogers RO3003 high frequency PCB Substrate |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

4.3 Wangling

Wangling materials also demonstrate competitive DK thermal coefficients. Through innovative technology and strict quality control, Wangling offers materials with controllable DK thermal coefficients, providing stable performance for high-frequency circuits across various frequencies and temperatures. |

|

|

| |

|

|

|

|

| |

|

4.4 Summary of CPB Material |

|

|

| |

|

The following table summarizes the key features of Taconic, Rogers, and Wangling material. |

|

|

| |

|

Supplier |

DK Thermal Coefficient |

Applications |

Thermal Stability |

Taconic |

Low and stable |

Communication, Radar |

Slight increase at high temperatures |

Rogers |

Low and stable |

Microwave, RF |

Minimal DK value changes, good thermal stability |

Wangling |

Controllable |

Various frequencies |

Stable DK values, widely applicable |

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

5. Concluding Remarks |

|

|

| |

|

“In the vast universe of high-frequency PCBs, the thermal coefficient of DK is the shining star, guiding the development of the electronics industry.” Whether in communication devices, aerospace, or medical electronics, selecting appropriate PCB materials and closely monitoring the TCDk is crucial for optimizing design and enhancing quality. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|