| |

|

| |

|

|

|

|

|

| |

|

What is Tg in High Frequency PCB ? |

|

|

|

| |

|

1. Definition of Tg |

|

|

|

| |

|

In the field of PCBs, Tg (Glass Transition Temperature) denotes the temperature at which a material transitions from a glassy state to a rubbery state. At this temperature, the physical properties of the material undergo significant changes. In the glassy state, the material is hard and brittle; as the temperature rises above Tg, it begins to soften and exhibit rubber-like elasticity. This parameter is crucial for the thermal performance and reliability of PCBs. |

|

|

| |

|

|

|

|

| |

|

2. Importance of Tg |

|

|

| |

|

2.1 Dimensional Stability |

|

|

| |

|

Below Tg, the dimensions of PCB materials remain relatively stable. When temperatures approach or exceed Tg, the material can expand and contract, potentially leading to changes in line spacing and separation between copper foil and substrate. For instance, in high-precision PCB designs, such as those used in high-speed communication devices, a low Tg can result in signal transmission line spacing changes due to increased operating temperatures, which may affect signal integrity. |

|

|

| |

|

|

|

|

| |

|

2.2 Mechanical Property Changes |

|

|

| |

|

Below Tg, materials possess good mechanical strength and can withstand certain external forces. Once Tg is exceeded, the material softens and its mechanical strength decreases. During PCB assembly processes, such as through-hole insertion or soldering, exceeding the material's Tg can cause deformation, impacting subsequent assembly and usage.

|

|

|

| |

|

|

|

|

| |

|

3. Application Cases |

|

|

| |

|

For electronic devices that operate in high-temperature environments, such as PCBs in automotive electronic control systems, materials with a high Tg are essential. The temperature in an engine compartment can be quite high, and high Tg PCB materials ensure that the performance and dimensions of the circuit board remain stable under such conditions, preventing failures. |

|

|

| |

|

|

|

|

| |

|

4.2 Benefit of Taconic RF-60TC's Tg |

|

|

| |

|

Speaking of the Tg of high-frequency PCBs, Taconic RF-60 springs to my mind. RF-60 laminate has high Tg above 300°C and is designed for high-frequency and high-temperature applications, offering excellent electrical performance. Next,Let's delve into the key details and benefits of this remarkable product. |

|

|

| |

|

|

|

|

| |

|

4.1 RF-60TC Material Properties |

|

|

| |

|

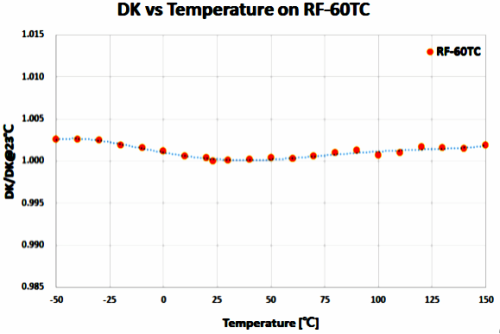

RF-60TC is a PTFE based, ceramic filled fiberglass substrate, delivering excellent electrical and thermal properties. At 10 GHz, it has a dielectric constant (Dk) of 6.15, ensuring minimal signal loss. With a dissipation factor of 0.002 at 10 GHz/23°C, it reduces signal attenuation and distortion. Its thermal coefficient of Dk is -3.58 ppm/°C from -50°C to 150°C, ensuring stable performance.RF-60TC laminate operates reliably within a temperature range from -40°C to +85°C,which is suitable for both extreme and moderate temperature environments. |

|

|

| |

|

|

|

|

| |

|

4-1.TCDK of RF-60TC |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

4.2 Benefit of Taconic RF-60TC High Frequency PCB |

|

|

| |

|

Benefit |

Description |

Loss Tangent |

Minimizes dielectric loss, reduces signal attenuation, boosts signal quality, power efficiency & system performance. |

Thermal Conductivity |

High conductivity dissipates heat well, extends component life in high-power apps. |

Dimensional Stability |

Ensures precise interconnection, vital for tight tolerance apps. |

Z-Axis CTE |

Low at 40 ppm/°C, cuts thermal cycling stress failures, heightens reliability. |

Adhesion |

Bonds excellently to copper, cuts insertion loss, aids signal integrity. |

DK Stability |

Keeps dielectric constant steady over freq. & temp., ensures consistent elec. performance. |

Moisture Absorption |

Low rate preserves prop. in humidity, key for long-term use. |

|

|

|

| |

|

|

|

|

| |

|

5. Typical Applications |

|

|

| |

|

- High Power Amplifiers

- Miniaturized Antennas

- GPS, Patch, RFID reader

- Filters, Couplers & Dividers

- Satellites

|

|

|

| |

|

|

|

|

| |

|

6. Final Thoughts |

|

|

| |

|

"In PCB design, Tg is not only a critical indicator of material performance but also a cornerstone for ensuring the reliability and stability of circuits." |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|