| |

|

| |

|

|

|

|

|

| |

|

What is TCK in High Frequency PCB? |

|

|

|

| |

|

1. Unveiling the Mystery of TCK |

|

|

|

| |

|

TCK, namely Trace Characteristic Key, refers to the key indicators of circuit characteristics, covering multiple professional parameters such as impedance matching, signal transmission rate, and attenuation characteristics. These parameters work in concert to precisely control the transmission behavior of high-frequency signals on PCB circuits, ensuring the integrity and stability of signals and laying the foundation for the high-performance operation of high-frequency PCBs. |

|

|

| |

|

|

|

|

| |

|

2. Critical Influence of TCK |

|

|

| |

|

When PCB encounters TCK, it is like Iron Man putting on his armor, instantly possessing the power to conquer all difficulties. Taking 5G base station construction as an example, with TCK technology, PCBs can stably carry the high-speed transmission of massive data at ultra-high frequencies, ensuring low-latency and error-free signals, allowing information to be transmitted at lightning speed and laying a solid foundation for the rapid development of the intelligent era. |

|

|

| |

|

|

|

|

| |

|

3. Factors and Optimization for TCK Effectiveness |

|

|

| |

|

However, TCK's effectiveness is limited by multiple elements, demanding a multi-faceted improvement approach. |

|

|

| |

|

|

|

|

| |

|

3.1 Material Compatibility |

|

|

| |

|

High-frequency application scenarios differ in PCB substrate needs. In millimeter-wave communication, substrates with low dielectric constant and loss tangent should be chosen to cut signal attenuation and meet TCK standards. |

|

|

| |

|

|

|

|

| |

|

3.2 Manufacturing Process Precision |

|

|

| |

|

Processes like circuit etching precision and laminate stability tie directly to TCK. Precise etching keeps line width and spacing uniform as per design, averting impedance mismatch from deviations. Stable lamination bonds circuit layers, preventing crosstalk and upholding TCK reliability. |

|

|

| |

|

|

|

|

| |

|

3.3 Environmental Adaptability Design |

|

|

| |

|

Given PCBs' diverse environments, from hot-humid industries to cold-dry outdoors, TCK design must factor in surroundings. Optimizing protective coatings, for instance, boosts humidity resistance, warding off short circuits due to moisture and ensuring TCK stability in tough conditions. |

|

|

| |

|

|

|

|

| |

|

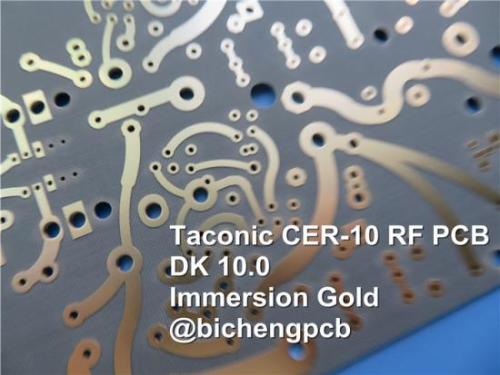

4. Overview of Taconic CER-10 PCB |

|

|

| |

|

Speaking of the TCK, CER-10 high-frequency PCB springs to my mind. Taconic CER-10 is an organic-ceramic laminate belonging to the ORCER family of Taconic's products. It is founded on woven glass reinforcement and showcases exceptional interlaminar bond strength and solder resistance. Taconic CER-10 laminate offers significant advantages in terms of TCK, supported by key data. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

4.1 Strengths of Taconic CER-10 laminate's TCK |

|

|

| |

|

- High Dielectric Constant Stability

At 10 GHz/23°C, the dielectric constant is 10 ± 0.05, ensuring stable signal transmission speed and reducing delay and distortion in high-frequency applications like phased array radars.

Loss factor at 10 GHz/23°C is as low as 0.0035, maintaining signal strength and integrity for long-distance and high-frequency transmissions.

- Excellent Thermal Stability

Thermal conductivity is 0.63 W/mK, with thermal expansion coefficients of 13 ppm/°C (X), 15 ppm/°C (Y), and 46 ppm/°C (Z). Operating temperature range is -55°C to 288°C, ensuring stability in high temperatures and extending equipment lifespan.

- Good Mechanical Properties

Flexural and tensile strengths are high, with peel strength at 9 N/mm. This durability supports reliability in aerospace and production environments.

Water absorption rate is only 0.02%, maintaining stable electrical properties in humid conditions and preventing signal attenuation.

- Good Dimensional Stability

Dimensional stability in machine direction (MD) is 0.0002 in/in and cross direction (CD) is 0.0003 in/in, ensuring accuracy in high-precision assembly of high-frequency printed circuit boards.

4.2 CER-10 PCB Capability

PCB Material: |

Organic-ceramic Laminate based on Woven Glass Reinforcement. |

Designation: |

CER-10 |

Dielectric constant: |

10 |

Layer count: |

Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

PCB thickness: |

25mil (0.635mm), 30mil(0.762mm), 47mil(1.194mm), 50mil (1.27mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG,Silver, Tin and OSP etc.. |

|

|

|

| |

|

5. Final Thoughts |

|

|

| |

|

From blueprint to physical PCB, TCK safeguards each step's accuracy. Only by grasping TCK's essence, managing factors, and constantly optimizing can high-frequency PCBs' full potential be tapped, propelling the electronics industry to new digital heights. |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|