| |

|

| |

|

|

|

|

|

| |

|

What is Specific Heat Capacity in High Frequency PCB? |

|

|

|

| |

|

1. Definition of Specific Heat Capacity |

|

|

|

| |

|

Specific Heat Capacity generally refers to the ability of PCB materials to absorb, conduct, and release heat under specific conditions. This ability is not only determined by the material's physical properties such as thermal conductivity and coefficient of thermal expansion, but is also influenced by the PCB's structure, layout, and operating environment. |

|

|

| |

|

|

|

|

| |

|

2. Importance of Specific Heat Capacity Capacity |

|

|

| |

|

In high-frequency circuits, heat management is crucial. Improper heat accumulation can lead to performance degradation, signal distortion, and even equipment damage. Therefore, optimizing Specific Heat Capacity management holds immense value in enhancing the overall performance of the equipment. |

|

|

| |

|

|

|

|

| |

|

3. Optimization Measures |

|

|

| |

|

3.1 Optimizing PCB Layout

A reasonable layout can effectively distribute hot spots, reducing the risk of localized overheating. High-power components should be kept away from sensitive elements and placed in positions conducive to heat dissipation.

3.2 Selecting Materials with High Thermal Conductivity

The thermal conductivity of the substrate material directly impacts the PCB's heat dissipation performance. Choosing materials with high thermal conductivity, such as ceramic substrates or specially formulated FR-4, can improve heat transfer efficiency.

3.3 Increasing Copper Foil Thickness

Copper foil is not only used for circuit connections but also serves as an important pathway for heat transfer. Increasing the thickness of the copper foil provides a larger heat conduction area, reducing thermal resistance and enhancing cooling effects.

3.4 Designing Heat Dissipation Channels

Incorporating heat dissipation channels, such as thermal vias and slots, into the PCB design can facilitate rapid heat transfer from the heat source to the PCB's cooling area. 3.5 Using Thermal Pads and Heat Sinks Employing thermal pads between high-power components and the PCB, as well as installing heat sinks externally on the PCB, can significantly improve heat dissipation efficiency.

|

|

|

| |

|

|

|

|

| |

|

4.Strengths of RT/duroid 6035HTC's Specific Heat Capacity |

|

|

| |

|

When discussing the specific heat capacity in high-frequency PCBs, Rogers RT/duroid 6035HTC that combines ceramic-filled PTFE composites immediately comes to my mind. The specific heat capacity advantages of RT/duroid 6035HTC material are mainly shown in the following aspects. |

|

|

| |

|

|

|

|

| |

|

4.1 High thermal conductivity |

|

|

| |

|

Data: RT/duroid 6035HTC has a thermal conductivity of 1.44 W/m/K @ 80°C, while the standard RT/duroid 6000 product has a thermal conductivity only about 1/2.4 of it.

Analysis: High thermal conductivity allows the material to transfer heat quickly. In high - power applications like several - hundred - watt microwave amplifiers, it can lower its own temperature, manage heat efficiently, and prevent performance decline or damage from heat build - up. |

|

|

| |

|

|

|

|

| |

|

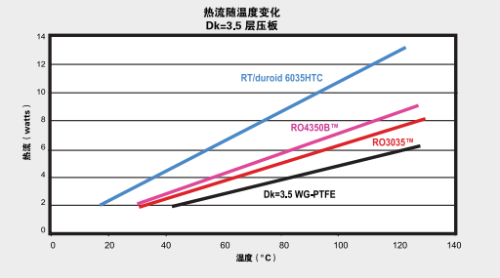

4-1. Graph of Heat Flow Variation with Temperature for 3.5 Dk Laminates |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

As can be seen from the above figure, among the four different laminate materials with a Dk of 3.5, RT/duroid 6035HTC has the highest resistance heat dissipation efficiency and the slowest temperature increase. |

|

|

| |

|

|

|

|

| |

|

4.2 Strong dielectric heat - dissipation

Data: At 10GHz, the material has a relative permittivity of 3.50 with a tolerance within 0.05 across the circuit board.

Analysis: The stable and suitable dielectric constant, along with the small tolerance, helps control electromagnetic wave propagation under high - frequency electric fields, reducing dielectric losses and heat generation. This enhances dielectric heat - dissipation, lowers the operating temperature of high - power devices, and ensures their stability and reliability during high - power operation.

4.3 Close CTE match with copper

Data: The RT/duroid 6035HTC material has a CTE of 19ppm/°C in the x and y axes, close to that of copper.

Analysis: This close CTE match reduces stress from thermal expansion differences when temperature changes. It prevents issues like circuit - board delamination and deformation, improving the board's structural integrity and reliability in various temperature conditions, thus ensuring thermal management and device operation. |

|

|

| |

|

|

|

|

| |

|

5. PCB Capability(RT/duroid 6035HTC) |

|

|

| |

|

PCB Capability (RT/duroid 6035HTC) |

PCB Material: |

Ceramic-filled PTFE composites |

Designation: |

RT/duroid 6035HTC |

Dielectric constant: |

3.50±0.05 |

Layer count: |

Double Layer, Multilayer, Hybrid PCB |

Copper weight: |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

PCB thickness: |

10mil (0.254mm), 20mil(0.508mm), 30mil (0.762mm), 60mil(1.524mm) |

PCB size: |

≤400mm X 500mm |

Solder mask: |

Green, Black, Blue, Yellow, Red etc. |

Surface finish: |

Bare copper, HASL, ENIG, OSP etc.. |

|

|

|

| |

|

|

|

|

| |

|

6. Conclusion |

|

|

| |

|

Through precise heat management design, we can ensure stable operation of equipment under high-frequency, high-power conditions, driving continuous progress in electronic technology. As the golden phrase goes, "Precise control is key in the field of PCB heat management." |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|