| |

|

| |

|

|

|

|

|

| |

|

What is Solder Mask in High Frequency PCB ? |

|

|

|

| |

|

1. Definition and Function |

|

|

|

| |

|

Solder mask includes top solder mask and bottom solder mask. The solder mask is an insulating material covering the copper foil traces on the surface of a PCB. Its primary function is to prevent short - circuits during the soldering process, such as preventing solder from bridging between adjacent traces and pads where soldering is not required. For example, on a mobile phone PCB with dense traces, without a solder mask, solder bridging is likely to occur during surface - mount component soldering, resulting in short - circuits. Additionally, the solder mask provides certain protection to the copper traces on the PCB, preventing oxidation and corrosion of the copper traces. |

|

|

| |

|

|

|

|

| |

|

2. Manufacturing Process |

|

|

| |

|

Common methods for manufacturing the solder mask include screen printing and photo - imaging processes. In screen printing, liquid solder - resist ink is printed onto the PCB surface and then cured to form the solder mask. The photo - imaging process uses photolithography technology. Through steps such as exposure and development, the photosensitive solder - resist material forms the solder mask in the required areas. |

|

|

| |

|

|

|

|

| |

|

3. Color and Appearance |

|

|

| |

|

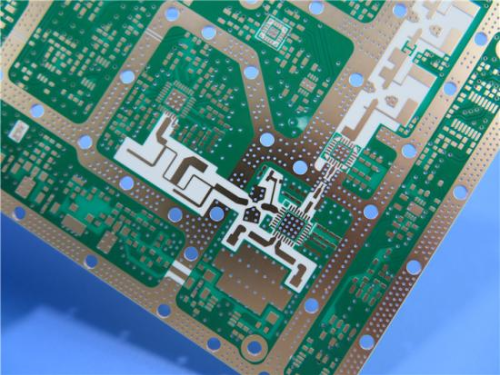

The solder mask is available in a variety of colors. The most common color is green, but other colors such as red, blue, and black are also available. In terms of appearance, the solder mask covers most of the copper trace areas, leaving openings only at the pads where soldering is needed, allowing the solder to come into contact with the pads for soldering. |

|

|

| |

|

|

|

|

| |

|

4.Strengths of RO4534 PCB's Solder Mask |

|

|

| |

|

When it comes to the application of board tooling holes in high-frequency PCBs, I can't help but think of Rogers RO4500™ laminates. Let's illustrate this by using RO4534 laminate as an example.

Rogers RO4534 High Frequency Laminates are materials based on hydrocarbon that are filled with ceramic and reinforced with glass. These cost-effective performance materials are specifically designed and produced to meet the unique requirements of the antenna market. |

|

|

| |

|

|

|

|

| |

|

4-1.Rogers RO4534 PCB |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

4.1 Excellent Process Compatibility |

|

|

| |

|

Compatibility with FR - 4 process: RO4534 PCB is highly compatible with FR - 4 process. For solder mask production, existing FR - 4 processes & equipment can be used, reducing defects risks like poor adhesion or uneven thickness, improving production efficiency & cutting costs. |

|

|

| |

|

|

|

|

| |

|

4.2 Outstanding Soldering Performance |

|

|

| |

|

Lead - free soldering compatibility: It's fully compatible with high - temp lead - free soldering. In such environment, it adapts well, reducing thermal shock & damage to solder mask, ensuring performance stability and minimizing cracking or peeling risks.

High thermal conductivity (0.600W/m - K) for heat dissipation: During soldering, it dissipates heat quickly, reducing overheating risks, maintaining solder mask stability, and improving soldering quality & efficiency. |

|

|

| |

|

|

|

|

| |

|

4.3 Stable Electrical Performance |

|

|

| |

|

Low loss characteristics (DF of 0.0027 at 10 GHz ): The low - loss helps reduce energy loss during signal transmission, decreasing thermal effect on solder mask, reducing cracking or peeling risks and soldering defects.

Stable dielectric constant (3.4 at 10 GHz): It maintains stable electric field distribution between solder mask and traces during soldering, reducing signal issues and impact on solder mask, ensuring performance consistency. |

|

|

| |

|

|

|

|

| |

|

4.4 Good Mechanical Properties |

|

|

| |

|

Low Z - axis CTE (46.0 µm/m - °C): When temperature changes, it reduces PCB's Z - axis expansion & contraction, decreasing stress on solder mask, reducing delamination & blistering risks, ensuring long - term stability & reliability.

Good dimensional stability: It has low dimensional change rate in X and Y directions. During soldering, PCB's size change is small, reducing stretching & squeezing on solder mask, maintaining its integrity & stability, and reducing cracking or peeling risks. |

|

|

| |

|

|

|

|

| |

|

4. RO4534 Capability |

|

|

| |

|

Let’s know more about the RO4534 PCB capability together. |

|

|

| |

|

PCB Capability (RO4534) |

Details |

PCB Material |

Ceramic-filled, Glass-reinforced Hydrocarbon |

Designation |

RO4534 |

Dielectric constant |

3.4 |

Dissipation Factor |

0.0027 at 10GHz |

Layer count |

Double Sided PCB, Multilayer PCB, Hybrid PCB |

Copper weight |

0.5oz (17 µm), 1oz (35µm), 2oz (70µm) |

PCB thickness |

20mil (0.508mm), 30mil (0.762mm), 60mil (1.524mm) |

PCB size |

≤400mm X 500mm |

Solder mask |

Green, Black, Blue, Yellow, Red etc. |

Surface finish |

Bare copper, HASL, ENIG, Immersion silver, Immersion tin, OSP, Pure gold plated etc. |

|

|

|

| |

|

|

|

|

| |

|

5.Takeaways |

|

|

| |

|

Solder mask in high-frequency PCBs acts as a guardian. By preventing short circuits and protecting copper, it enables seamless signal transmission and enhances the durability of the PCB for demanding high-frequency operations. |

|

|

| |

|

|

|

|

| |

|

Founded in 2003, Shenzhen Bicheng Electronics Technology Co., Ltd is an established high frequency PCB supplier and exporter in Shenzhen, China, serving customers worldwide.

We are devoted to delivering high-frequency PCB products and solutions of the highest quality, along with customized service. Feel free to consult and contant at any time !

Visit https://www.bicheng-enterprise.com to learn more.

Unlock its full potential by contacting Vicky at v.xie@bichengpcb.com. |

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|